How to Choose a Reliable and Durable Rocker Switch?

As a leading Chinese switch manufacturer, we provide high-quality rocker switches known for their reliability and durability. Our switches feature robust electrical ratings, excellent environmental resistance, and impressive life cycle ratings, ensuring long-term performance. We use premium materials and maintain strict quality control, offering a variety of circuit configurations and mounting options to fit diverse applications.

Our products meet international safety standards, including UL, CE, and RoHS, making them suitable for various industries, from automotive to consumer electronics. By choosing our switches, you invest in durable solutions that enhance product reliability. Whether for new designs or upgrades, our rocker switches deliver the perfect balance of functionality and quality, ensuring your products remain competitive and reliable in the market. Trust us to provide switches that meet your current needs and anticipate future challenges, ensuring ongoing performance in your applications.

Types of Rocker Switches

Types of Rocker Switches

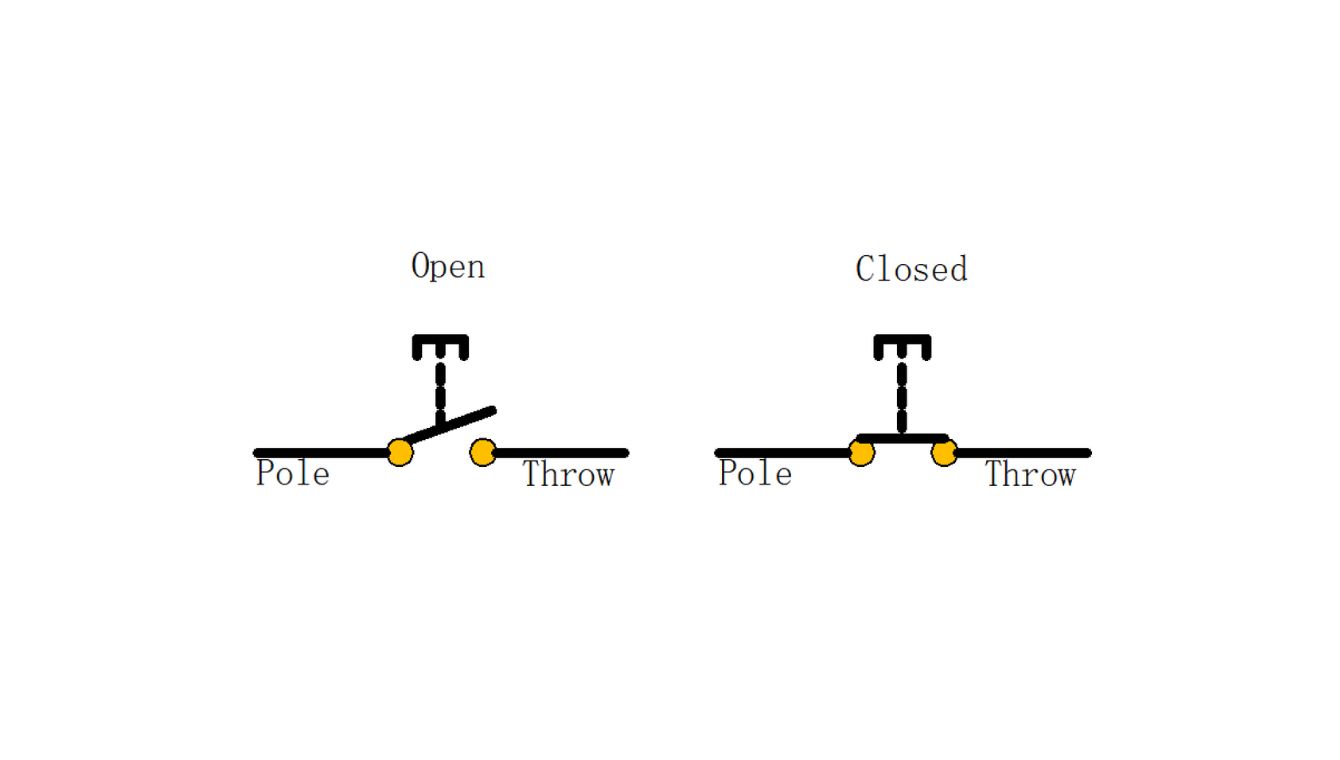

Single Pole Single Throw (SPST)

Has one circuit with one input and one output terminal.

Functions as a simple ON-OFF switch.

Example: Turning a desk fan ON or OFF with a single rocker.

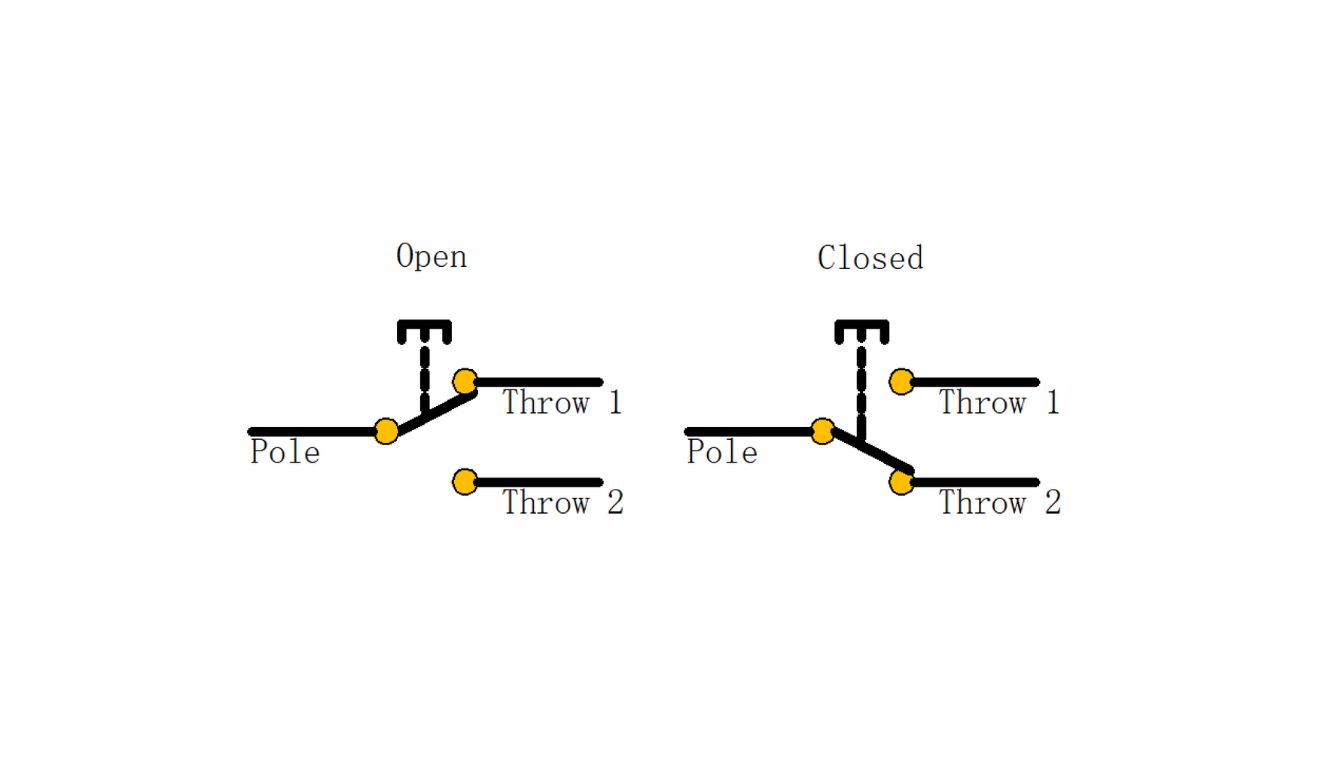

Single Pole Double Throw (SPDT)

Has one input terminal connected to one of two output terminals.

Allows switching between two circuits or options, such as power sources or operating modes.

Often called a three-way switch.

There are several common types of rocker switches, classified based on their pole and throw configurations, switching functions, and other features:

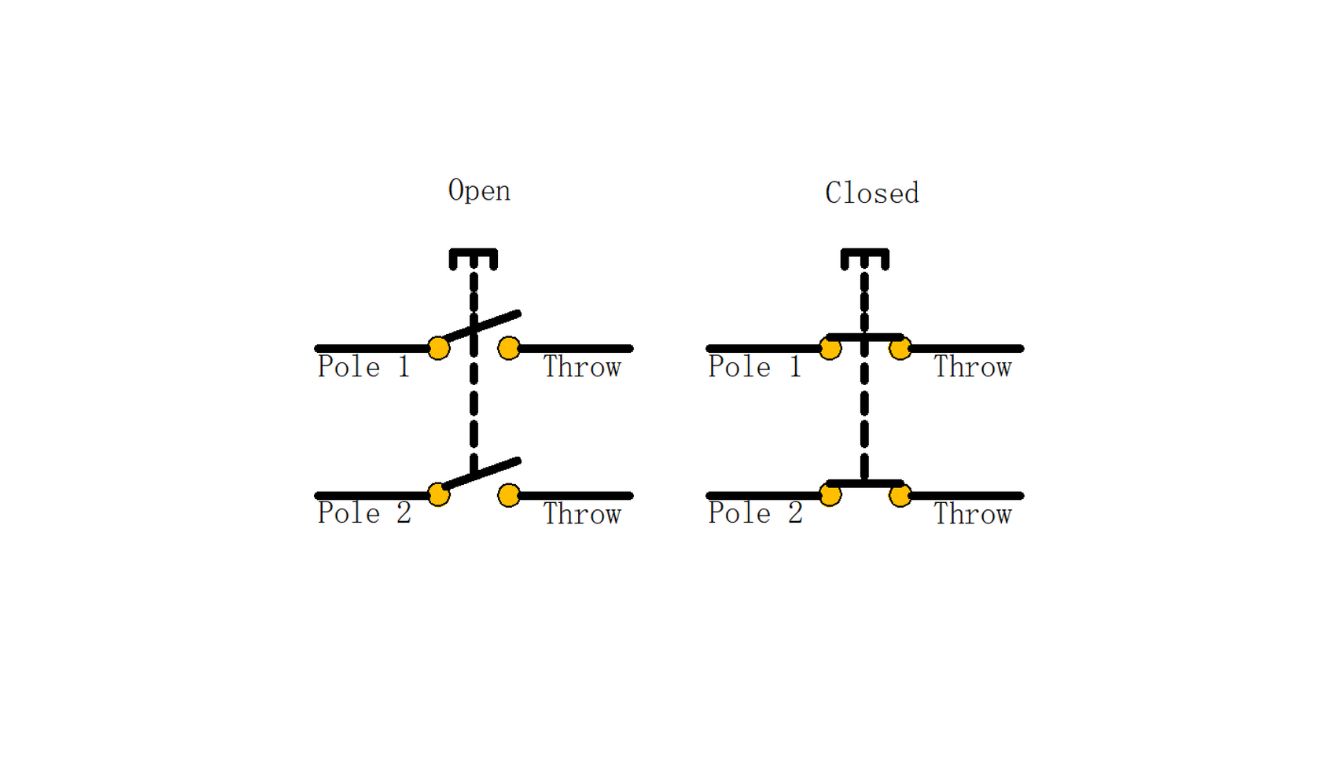

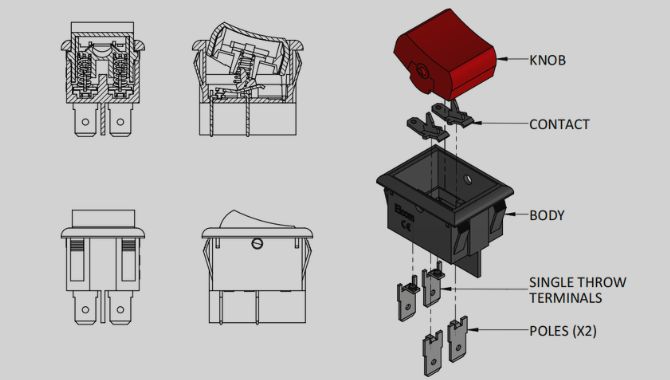

Double Pole Single Throw (DPST)

Controls two separate circuits simultaneously with one switch.

Has two inputs and two outputs, turning two circuits ON or OFF together.

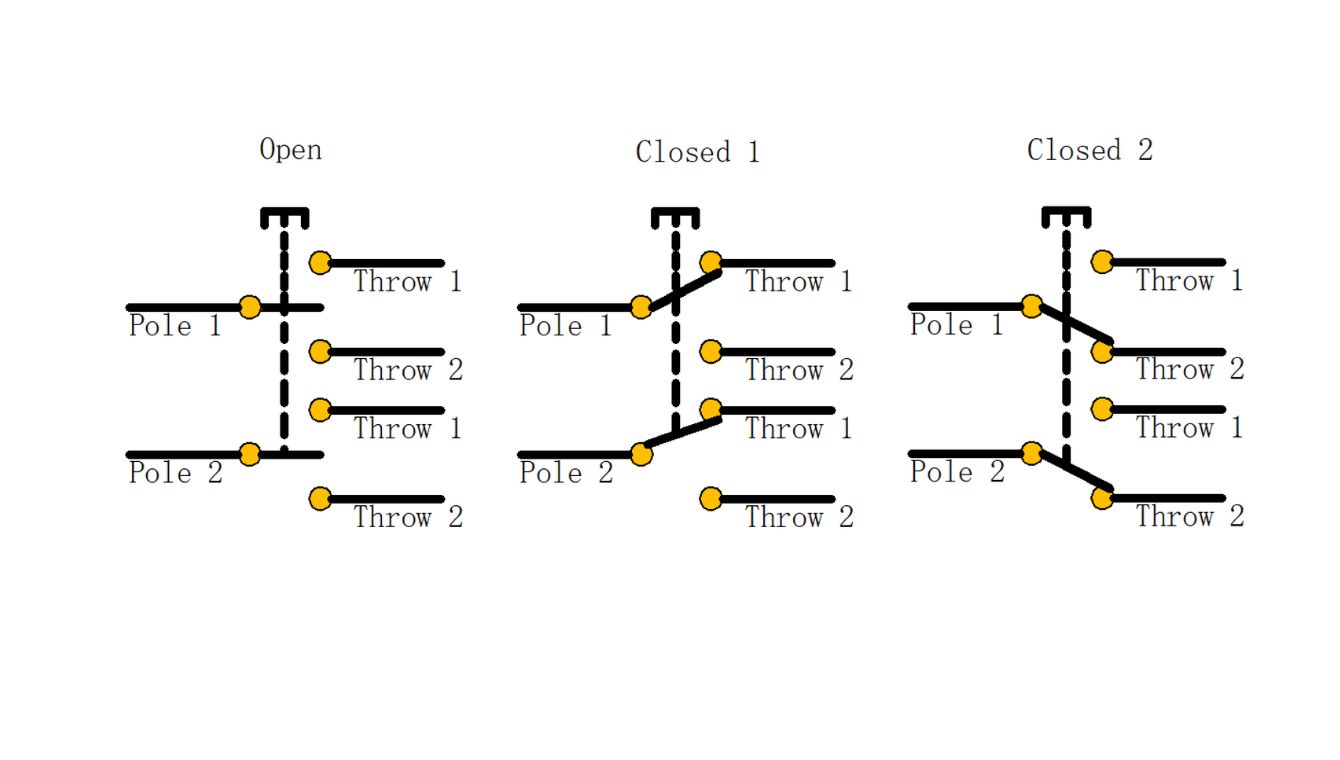

Double Pole Double Throw (DPDT)

Controls two circuits, each with two output options.

Can switch both circuits between two positions independently or simultaneously.

Often more complex, used for multi-circuit control.

Rocker Switch Waterproof Cover

Rocker Switch Waterproof Cover: Our Chinese-manufactured covers protect rocker switches from water, dust, and debris, ensuring reliability in harsh environments. Features include high-quality materials, robust sealing, and easy installation. Choose us for superior durability, competitive pricing, and fast shipping. Perfect for marine, automotive, and industrial applications. Click to learn more!

With Full Product Certification

Rocker Switch Applications

Marine and Boating

Outdoor Equipment

Industrial and Manufacturing

Automotive

Laboratory and Medical Equipment

Pool and Spa Controls

Rocker Switch VS Toggle Switch

| Feature | Rocker Switches | Toggle Switches |

|---|---|---|

| Design | Flat, wide surface | Lever mechanism |

| Operation | Rocks back and forth | Flipped up or down |

| Ease of Use | Easier to operate with one hand | May require more force |

| Applications | Common in household appliances | Used in both household and industrial settings |

| Versatility | Primarily on/off | Can have multiple positions |

Rocker Switches More Related Articles

equip yourself with the knowledge shared in this article to smoothly rock your way towards an optimal electrical solution! how does rocker switch work

A single pole switch is an electrical switch that controls one circuit by opening or closing the connection. It has two terminals and is commonly used to turn lights or devices on and off from a single location.

A double pole switch is an electrical switch that controls two separate circuits at the same time. It has four terminals and can switch both the live and neutral wires, making it ideal for safely isolating appliances from power sources.

Master the art of wiring 12V Rocker Switches and illuminate your world! Dive into our comprehensive guide and brighten your DIY electronics skills.

Related Product

FAQs

Rocker switches are commonly used in various applications, and people often have questions about them. Here are five of the most popular FAQs for rocker switches:

A rocker switch operates by tilting (or rocking) from one side to the other. This action either completes or interrupts the electrical circuit, turning a device on or off.

Rocker switches come in various types, including single-pole single-throw (SPST), single-pole double-throw (SPDT), double-pole single-throw (DPST), and double-pole double-throw (DPDT). SPST switches have a single circuit, while SPDT switches can control two circuits with one actuator. DPST and DPDT switches offer two or four circuits, respectively. Additionally, there are momentary rocker switches that only maintain their position while they are pressed.

Rocker switches are used in a variety of settings, including household appliances, automotive dashboards, marine equipment, industrial machinery, and electronic devices.

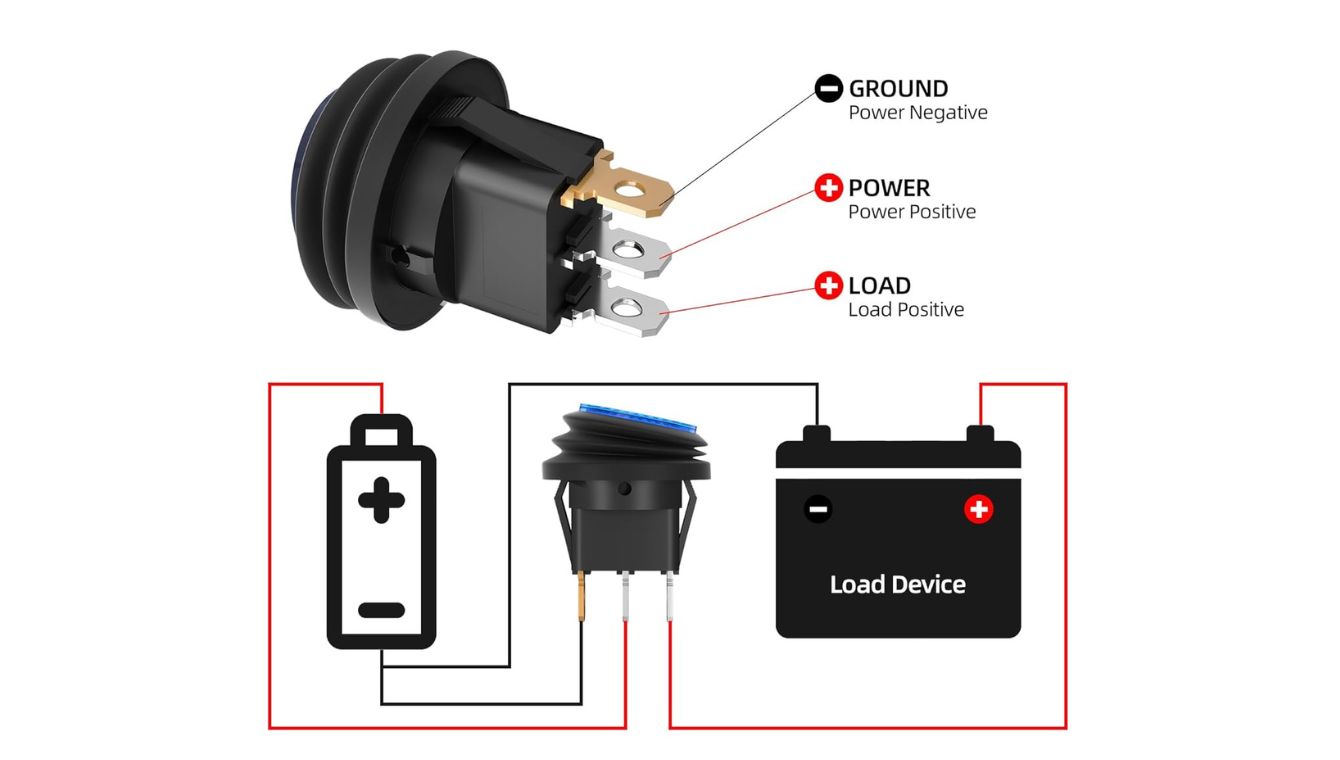

Wiring a rocker switch involves connecting the terminals on the switch to the power source and the device you want to control. It’s essential to follow a wiring diagram specific to your switch model to ensure correct connections and safe operation.、

Common terminals on a rocker switch include:

- COM (Common): The input terminal connected to the power source.

- NO (Normally Open): The terminal that connects to the load when the switch is in the ‘on’ position.

- NC (Normally Closed): The terminal that connects to the load when the switch is in the ‘off’ position.

Yes, there are specific rocker switches designed for marine environments. These switches are waterproof and corrosion-resistant, making them suitable for boats and other marine applications.

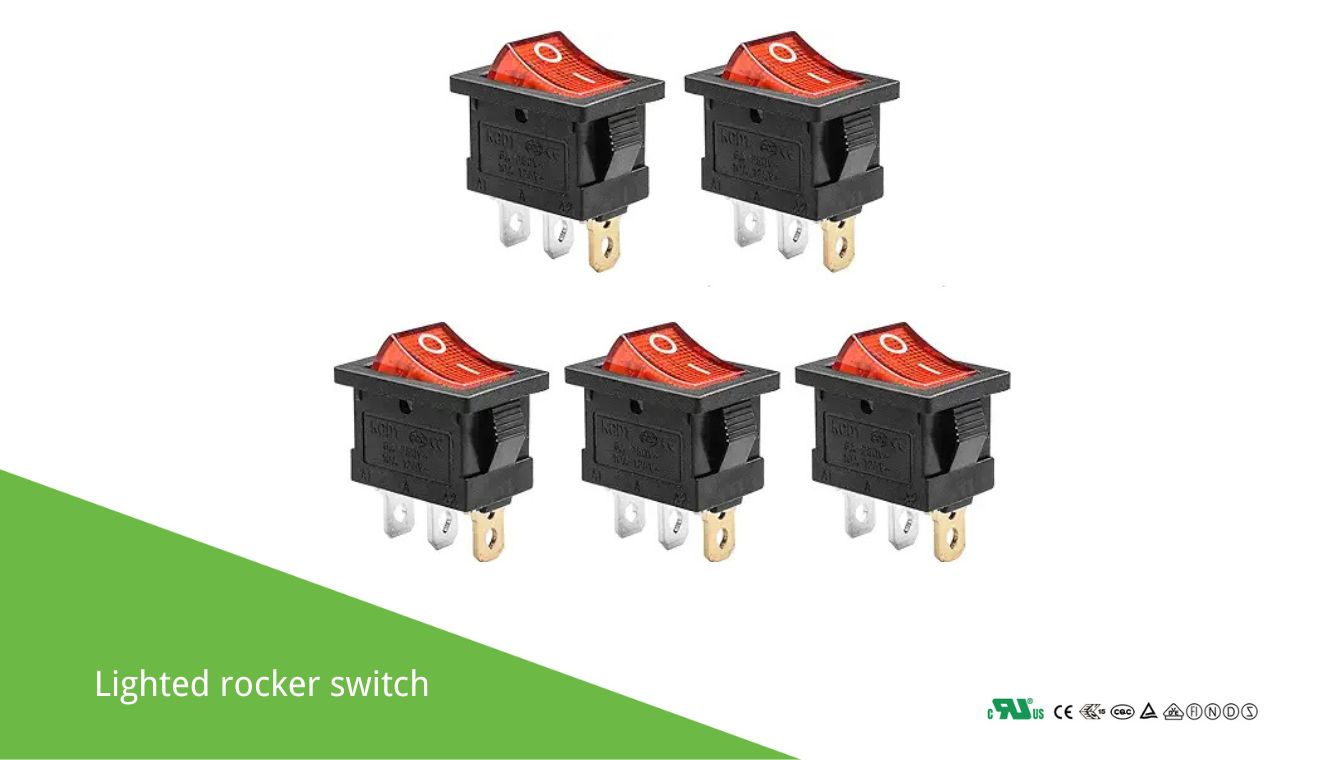

Yes, many rocker switches come with built-in LED or incandescent lights that illuminate when the switch is in the ‘on’ position, providing a visual indication of the switch’s status.

When selecting a rocker switch, consider factors such as the switch’s voltage and current rating, the type of load it will control, environmental conditions (such as exposure to water or dust), and any specific features like illumination or multiple poles/throws.

To maintain a rocker switch, regularly check for loose connections and signs of wear or corrosion. If a switch fails to operate, troubleshoot by checking the wiring connections, ensuring the power source is active, and replacing the switch if necessary.

Yes, we provide comprehensive technical support for installing and using rocker switches. Contact our customer service team for assistance with your specific model and application.