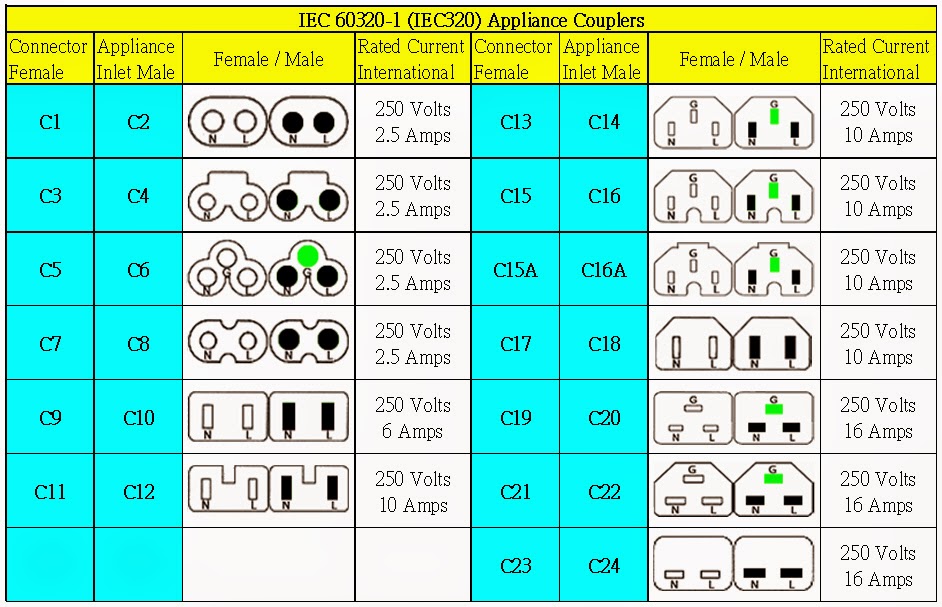

The International Electrotechnical Commission (IEC) connectors are standardized power connections used globally for the connection of electrical devices. They range from C1 to C20, each serving different applications, power capacities, and equipment types. This range allows for the safe, standardized connection of devices to power sources, ensuring compatibility and safety across various regions and devices. Here’s a breakdown to demystify the IEC C1-C20 connectors:

C1/C2 Connectors

- Use: Primarily used in very low power applications, such as electric shavers.

- Features: These are the smallest IEC connectors, with C1 being the male connector and C2 the female. The design is obsolete for most new devices.

C3/C4 Connectors

- Use: Similar to C1/C2 but slightly larger, these connectors are also rarely used in modern electrical equipment.

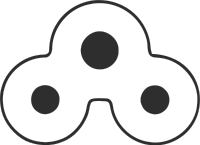

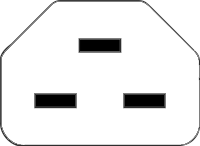

C5/C6 Connectors

- Use: Known as the “Mickey Mouse” connector due to the shape of the C5 female connector resembling Mickey Mouse’s silhouette. Commonly used for laptop power supplies and portable projectors.

- Features: Three pins, including a ground pin. The C6 is the male connector that plugs into the C5 socket.

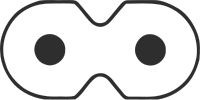

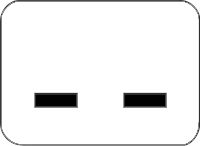

C7/C8 Connectors

- Use: Widely used for low-power devices like radios, game consoles, and video equipment. Known as the “figure-eight” or “infinity” connector.

- Features: Two pins, no ground connection. The C8 male connector plugs into the C7 female socket.

C9/C10 Connectors

- Use: Less common, these were used in some older audio and video equipment.

- Features: Similar to C7/C8 but with a different shape and not interchangeable.

C11/C12 Connectors

- Use: Now obsolete, these were used for some older pieces of equipment.

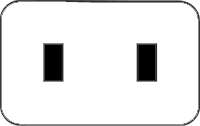

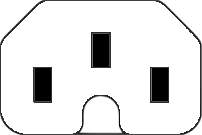

C13/C14 Connectors

- Use: One of the most common IEC connector pairs, used for connecting most computer, server, and networking equipment to power sources.

- Features: Three pins, including a ground pin. The C13 is the female socket, and the C14 is the male plug.

C15/C16 and C15A/C16A Connectors

- Use: Similar to C13/C14 but designed for higher temperatures, making them suitable for appliances like electric kettles.

- Features: The C15 female connector has a notch at the base to prevent it from being plugged into a C13 socket, which is not rated for high temperatures.

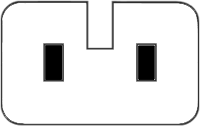

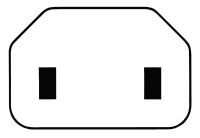

C17/C18 Connectors

- Use: A two-pin version of the C13/C14 without a ground pin, used for devices where grounding is not necessary or provided by another means.

- Features: Commonly found in household appliances like kitchen machines.

C19/C20 Connectors

- Use: Used for high-power devices, such as data center and IT equipment, that require more current than what C13/C14 can handle.

- Features: Similar to C13/C14 but larger and rated for higher currents.

C21/C22 Connectors

- Use: High-temperature versions of the C19/C20, capable of withstanding temperatures up to 155°C.

- Features: Designed for industrial and high-performance equipment that operates at higher temperatures.

Each of these connector types is designed with specific applications in mind, ensuring that devices receive the appropriate power supply in a safe and efficient manner. The connectors are distinguished by their physical shape, the number of pins, and their capacity for handling current and temperature, making it crucial to select the correct connector type for your specific application.