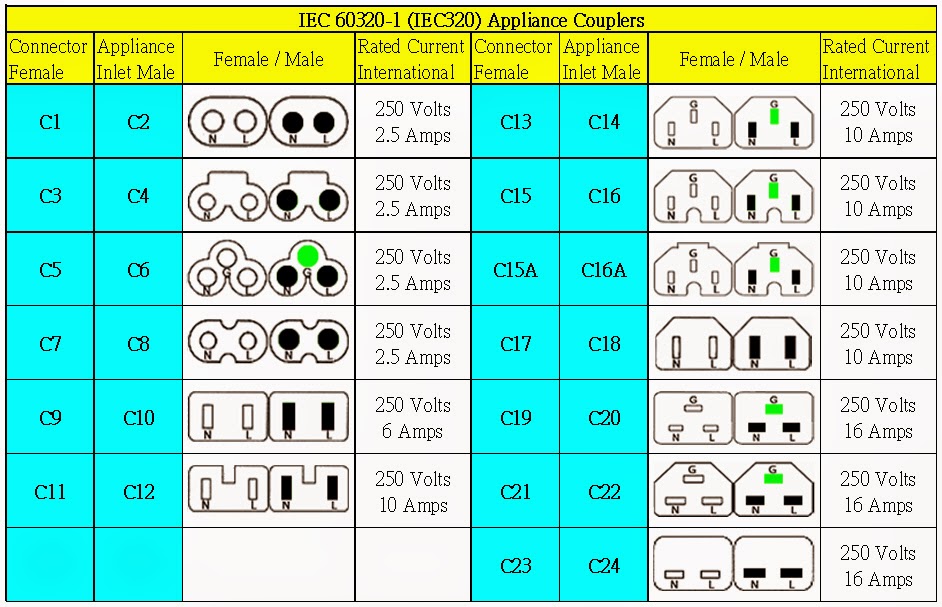

Understanding the pin layout in IEC connectors is crucial for ensuring compatibility and safety in electrical and electronic equipment connections. IEC connectors are categorized by the International Electrotechnical Commission with specific standards, notably the IEC 60320 series, which defines connectors for the connection of electrical equipment. Here’s a basic guide to understanding the pin layouts for some common types of IEC connectors:

Common IEC Connector Types and Their Pin Layouts:

- IEC 60320-1 C13/C14 Connectors:

- Type: These are among the most widely used IEC connectors for computer and server equipment.

- Pin Layout: The C13 (female) and C14 (male) connectors have three pins. These include two pins for the line (live) and neutral connections, and a third pin for the ground (earth).

- IEC 60320 C7/C8 Connectors:

- Type: Commonly used for portable electronics, like radio and laptop chargers.

- Pin Layout: The C7 (female) connector, known as the “figure-8” due to its shape, has two pins for line and neutral connections. It does not have a ground pin. The C8 (male) is its counterpart.

- IEC 60320 C5/C6 Connectors:

- Type: Often referred to as the “Mickey Mouse” connector due to the shape of the C5 (female) connector resembling Mickey Mouse’s silhouette, used for laptop power supplies.

- Pin Layout: This connector also features three pins – two for line and neutral, and one for ground.

- IEC 60320 C19/C20 Connectors:

- Type: Used for high-power equipment and IT applications.

- Pin Layout: Similar to the C13/C14, the C19 (female) and C20 (male) connectors have three pins for line, neutral, and ground but are designed for higher current ratings.

Key Considerations:

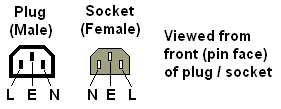

- Polarity and Grounding: It’s important to note that the specific pin assignments (which pin is line, neutral, and ground) can vary by country and equipment type, but grounding pins are typically longer or designed in a way to make first contact for safety.

- Voltage and Current Ratings: Each IEC connector type is rated for specific voltages and currents. It’s critical to match the connector to the power requirements of your device.

- Hot and Cold Conditions: Some connectors are specifically designed to withstand hot conditions, such as those used for kettles and other heating appliances, with a cut-out below the earth pin to prevent mating with non-heat resistant connectors.

When dealing with IEC connectors, always ensure that the connector type matches your equipment’s requirements and that you understand the pin layout and wiring specifications. Incorrect use or wiring can lead to equipment damage or pose serious safety risks. For detailed specifications and wiring instructions, refer to the equipment’s user manual or consult with a professional electrician, especially when dealing with high-powered or sensitive equipment.