How to select the button switch?

Button switches come in a wide variety of shapes, sizes, and colors, which can make selecting the right switch for your project a bit overwhelming. To simplify the process, we can follow these four principles to help you choose the most suitable button switch.

First, select the appropriate button type based on its intended use. Button switches are designed for various functions, such as rotary handle, push-button, emergency stop, or illuminated types. For example, models with indicator lights can display the operating status of equipment, while those with key-operated designs can prevent accidental operation by personnel.

Second, choose the button type according to the operating environment. Different applications require different levels of protection, such as open-type, protective, waterproof, or corrosion-resistant switches. For instance, a waterproof button switch installed on a panel can meet daily operational needs while effectively preventing liquid ingress, ensuring the equipment operates smoothly.

Next, select the button and indicator colors based on the operating status, indication requirements, and working conditions. Color selection typically follows industry standards, such as green for “start” or “on” and red for “stop” or “emergency.” Proper color design enhances operational intuitiveness and safety.

Finally, determine the number and configuration of buttons based on the control circuit requirements. Button switches are available in single-key, double-key, triple-key, and multi-key configurations. For example, when both “start” and “stop” controls are needed, two buttons can be integrated into a single button box, saving space and facilitating operation.

By considering these four principles, you can select a button switch that matches the functionality, reliability, and appearance required for your project, ensuring efficient equipment operation and operational safety.

Types of Push Button Switches

What is a Push Button switch?

A push button switch is an electromechanical device that completes or breaks an electrical circuit through a physical pushing action. At its core, this seemingly simple component consists of a movable actuator (the button) connected to a switching mechanism that changes state when pressure is applied. When the button is pressed, it either makes or breaks electrical contacts inside the switch body, allowing or preventing current flow through the connected circuit.

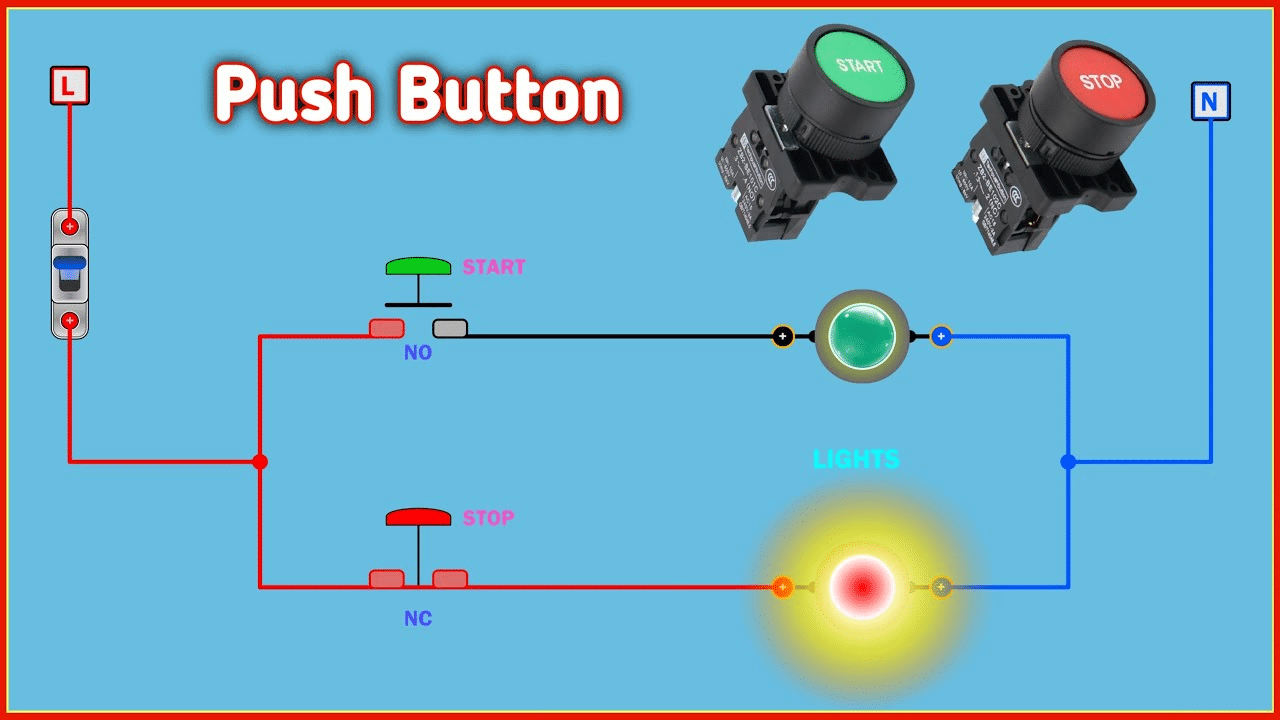

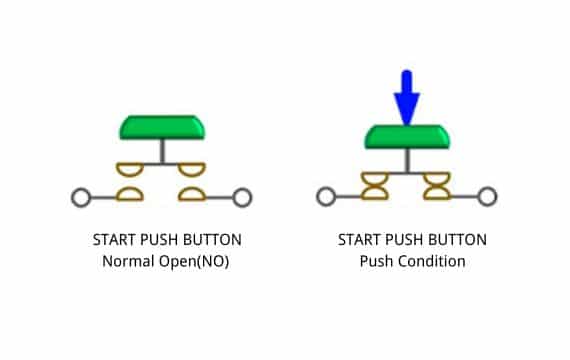

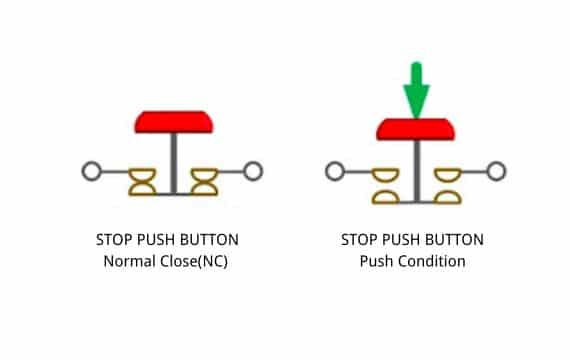

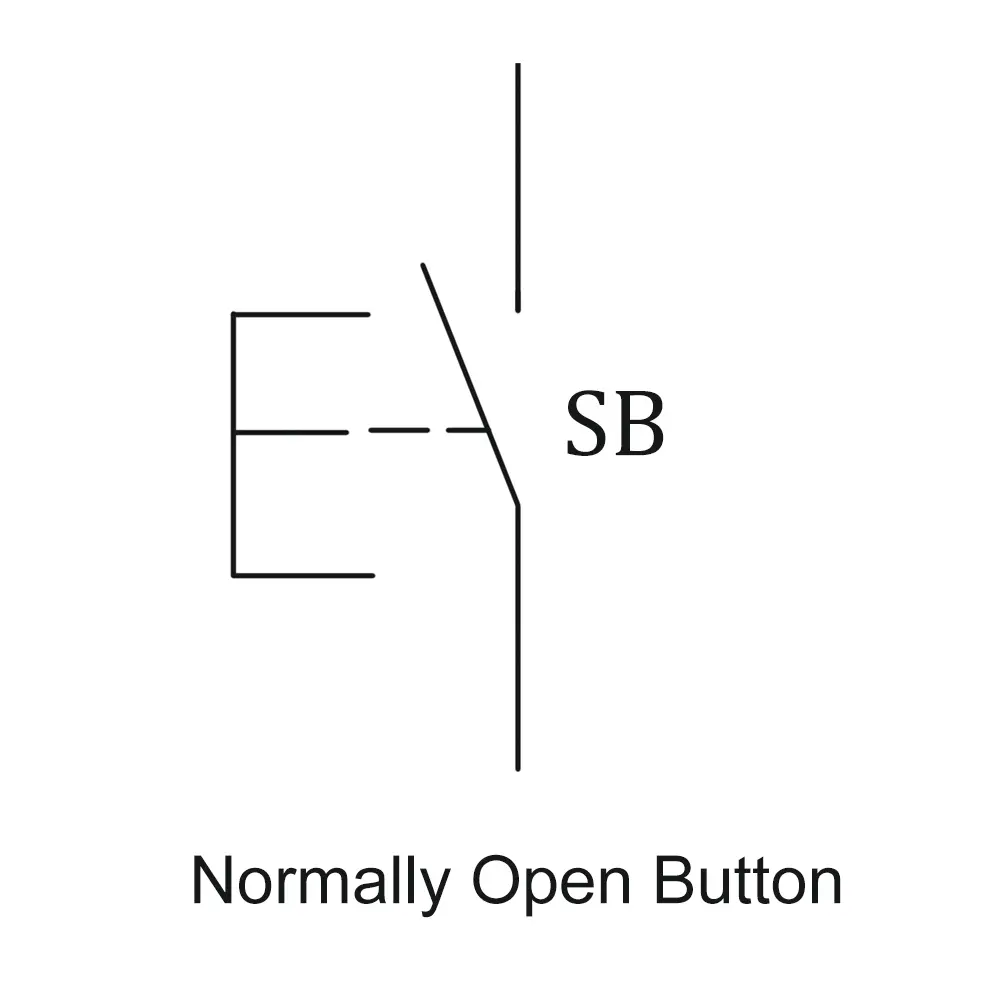

The working principle of a push button switch relies on mechanical movement translated into electrical action. When pressed, the actuator moves contacts together (normally open configuration) or separates them (normally closed configuration). This physical connection or disconnection creates a reliable and tactile method of controlling electrical circuits that has proven effective across countless applications for over a century.

Core Components and Construction

Understanding the construction of a push button switch helps procurement professionals evaluate quality, durability, and suitability for specific applications. While designs vary widely, most modern switches share these fundamental components:

- Actuator: The external button that receives physical pressure, typically made from durable thermoplastics or metal. Actuator design varies greatly, from simple round buttons to complex shapes with integrated guards, legends, or illumination features.

- Housing/Body: The outer casing that contains the internal mechanism and provides mounting features. Housing materials and design determine environmental protection, mounting options, and overall durability.

- Contact Assembly: The heart of the switch, consisting of conductive elements (typically copper alloys with silver, gold, or other precious metal plating) that make or break the electrical connection. Contact design directly influences electrical ratings, reliability, and lifecycle.

- Return Mechanism: Usually a spring system that returns the actuator to its resting position after pressure is released (in momentary switches). The design of this mechanism affects tactile feel, operating force, and long-term reliability.

- Terminals: The connection points for external wiring, available in various styles including solder, quick-connect, screw, and PCB mount configurations.

Additional components may include sealing gaskets for environmental protection, illumination elements (LEDs or lamps), contact blocks for multiple circuits, and specialized features for specific applications.

The quality of materials and precision of manufacturing in these components directly impact the performance, reliability, and lifespan of the push button switch. Premium switches utilize high-grade materials and tight manufacturing tolerances to ensure consistent operation over millions of cycles, while economy versions may compromise on materials or precision to achieve lower price points.

Push Button switch how to work?

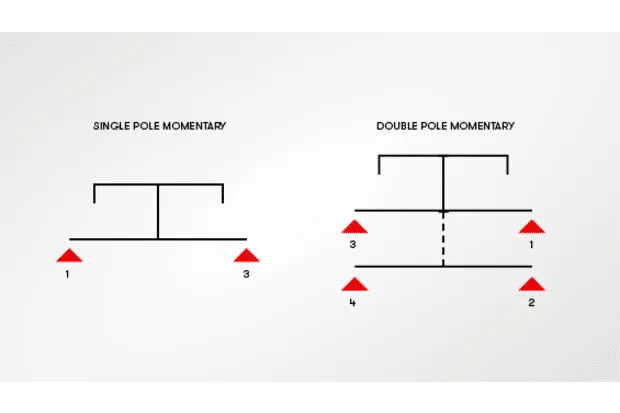

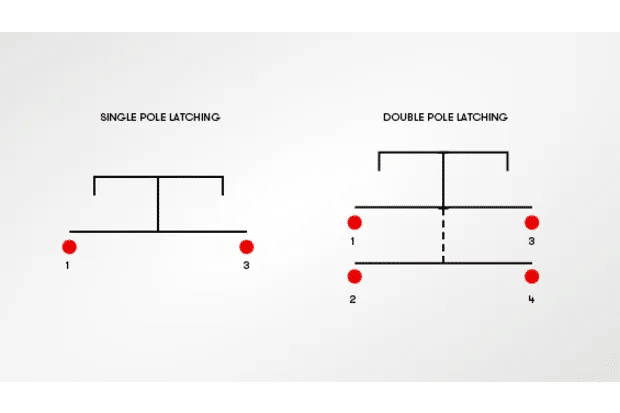

A push-button switch is a device that controls circuits through manual pressing. According to their operational characteristics, push-button switches can be divided into two main categories: momentary and maintained types. Momentary switches are activated (or deactivated) only when pressed, while maintained switches can remain in the on (or off) state after being pressed until they are operated again.

From a working principle perspective, the core mechanism of a push-button switch is to achieve circuit connection or disconnection through mechanical contact. When the operator presses the button, the internal spring mechanism drives the movable contact to connect with the fixed contact, thereby forming a closed circuit that allows current to flow and drive the load (such as lighting equipment or an electric motor) to operate. When the button is released, the contacts separate under the spring’s restoring force, breaking the circuit and stopping the load.

Push Button Switch Wiring Diagrams

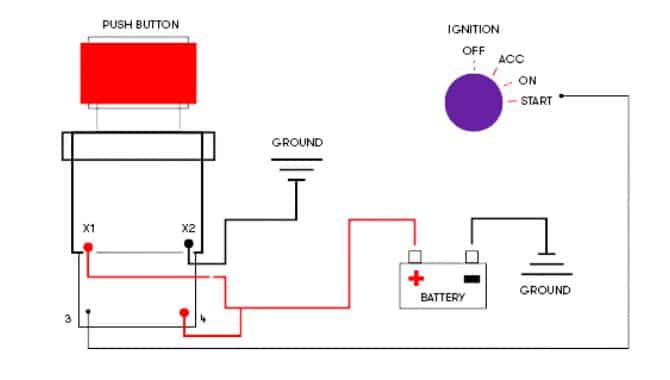

2 Pin Push Button Switch Wiring Diagrams

3 Pin Push Button Switch Wiring Diagrams

4 Pin Push Button Switch Wiring Diagrams

5 Pin Push Button Switch Wiring Diagrams

6 Pin Push Button Switch Wiring Diagrams

What's the Difference Between NO Contacts and NC Contacts?

NO Contacts:

usually, the initial state is not energized, the device is off, and only when you press the button, the device can start.

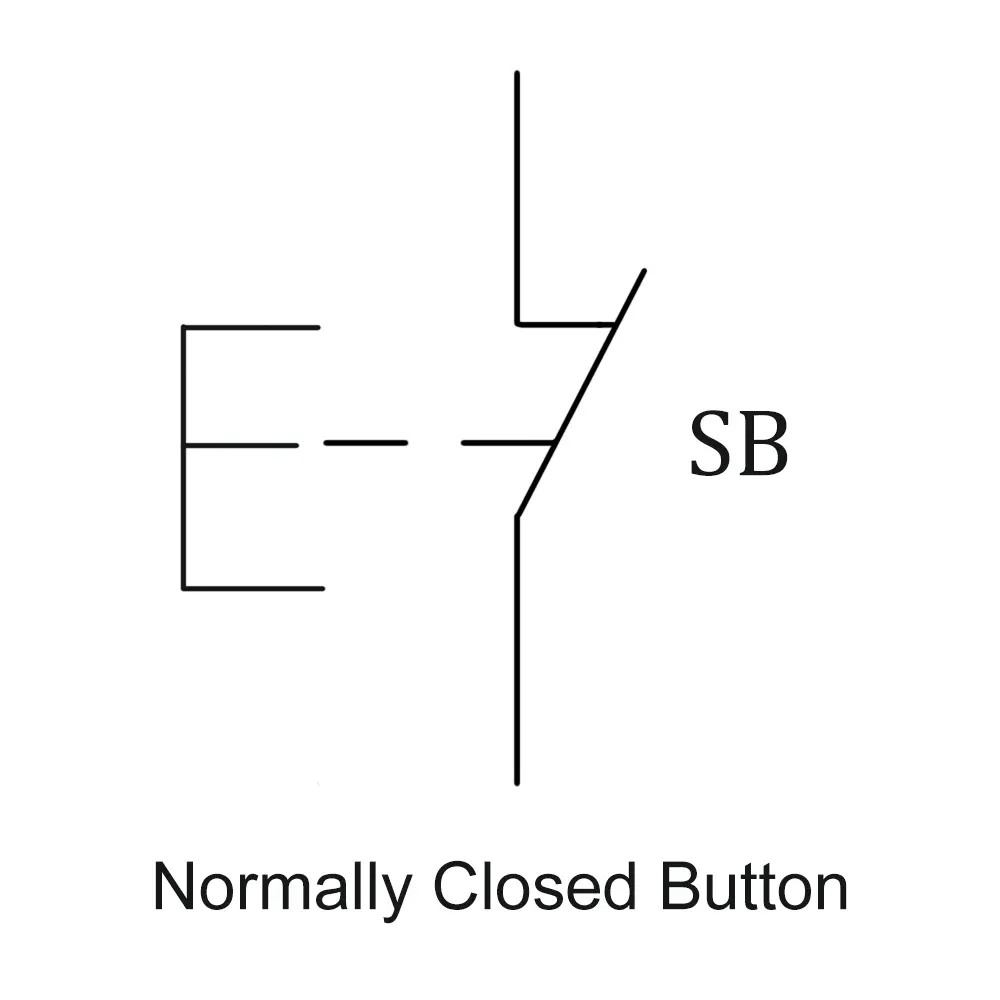

NC Contacts:

usually, the initial state is energized, and only when you press the button, the device will be powered off to realize the function.

What's the Difference Between Momentary and Maintained Push Button Switches?

Momentary Push Button Switches start working when you press the button and return to the initial state when you release it. A typical example is the Doorbell Switch, where the doorbell rings when you press the button and turns off when you release it.

Non-momentary Push Button switches, when you press the button to start working, when you release the button to maintain such a locked state, when you repeatedly press the button when it can return to the initial state.

Push Button Switch Types

A Normally Open (NO) button switch is a type of momentary switch that remains in the open (off) state under normal conditions, meaning the circuit is disconnected and no current flows through it. When the button is pressed, the internal contacts close, completing the circuit and allowing current to flow, which activates the connected load (such as a light or motor). Upon releasing the button, the contacts return to their original open position, breaking the circuit and deactivating the load.

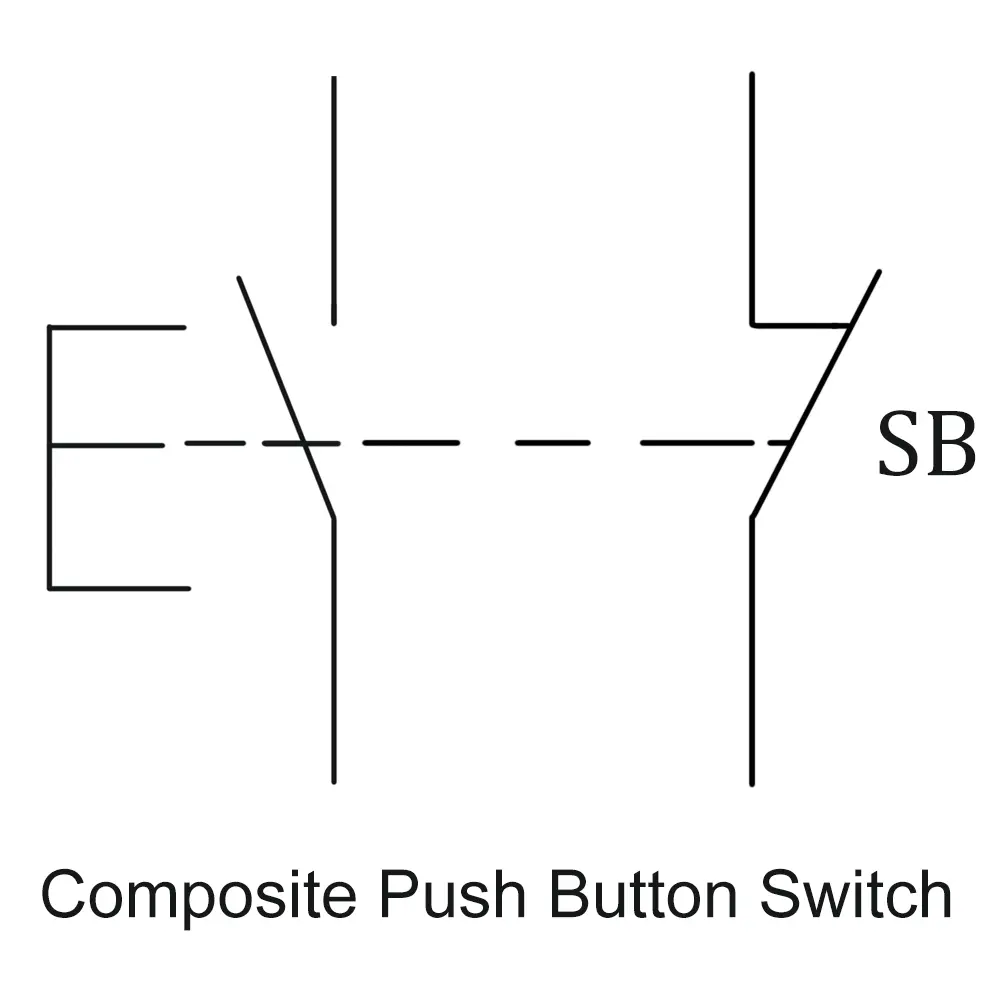

A Composite Push Button Switch is a multifunctional switching device that integrates multiple control functions into a single unit. It typically combines both Normally Open (NO) and Normally Closed (NC) contacts within one switch assembly, allowing it to perform multiple operations simultaneously or sequentially. This type of switch is commonly used in control systems where compact design and versatile functionality are required.

A Normally Closed (NC) Button Switch is a type of momentary switch that remains in the closed (on) state under normal conditions, meaning the circuit is connected and current flows through it. When the button is pressed, the internal contacts open, breaking the circuit and stopping the flow of current. Upon releasing the button, the contacts return to their original closed position, reconnecting the circuit and allowing current to flow again.

Related Product

Push Button Switch FAQ

Certainly! Here’s a FAQ (Frequently Asked Questions) list for push button switches, covering common queries and important aspects:

A push button switch is a simple type of switch mechanism used to control an aspect of a machine or process. It operates by pressing a button to make or break an electrical connection.

When pressed, the button either closes (makes) or opens (breaks) an electrical circuit. This action can start or stop electrical current flow, thereby controlling a device or process.

- Momentary: Activates only while the button is pressed and returns to its default state when released.

- Latching: Changes its state with each press, staying in either the closed or open position until pressed again.

They are used in a wide range of applications, including industrial equipment, consumer electronics, automotive interfaces, and household appliances.

While many push button switches are designed for low to moderate power applications, there are models rated for higher power and currents. It’s essential to check the switch’s specifications.

Durability varies by design and material. Industrial-grade switches are typically more robust than those used in light consumer applications.

Yes, many models come with built-in LEDs for illumination and indication purposes.

Some push button switches are designed to be waterproof, making them suitable for outdoor or harsh environmental applications. Check the IP rating for water and dust resistance.

Installation varies by model but generally involves inserting the switch into a pre-drilled panel hole and securing it, followed by connecting the electrical contacts.

A push button switch operates with a push action, while a toggle switch typically uses a lever that is toggled back and forth to change states.

Consider the electrical requirements (voltage, current), the type of operation (momentary or latching), environmental factors (waterproofing, dust resistance), size, and mounting style.

Yes, many s offer customization options like button color, labeling, and even switch configuration.