Enhancing Dust Collection Systems for Woodworking with Your Tool Switches

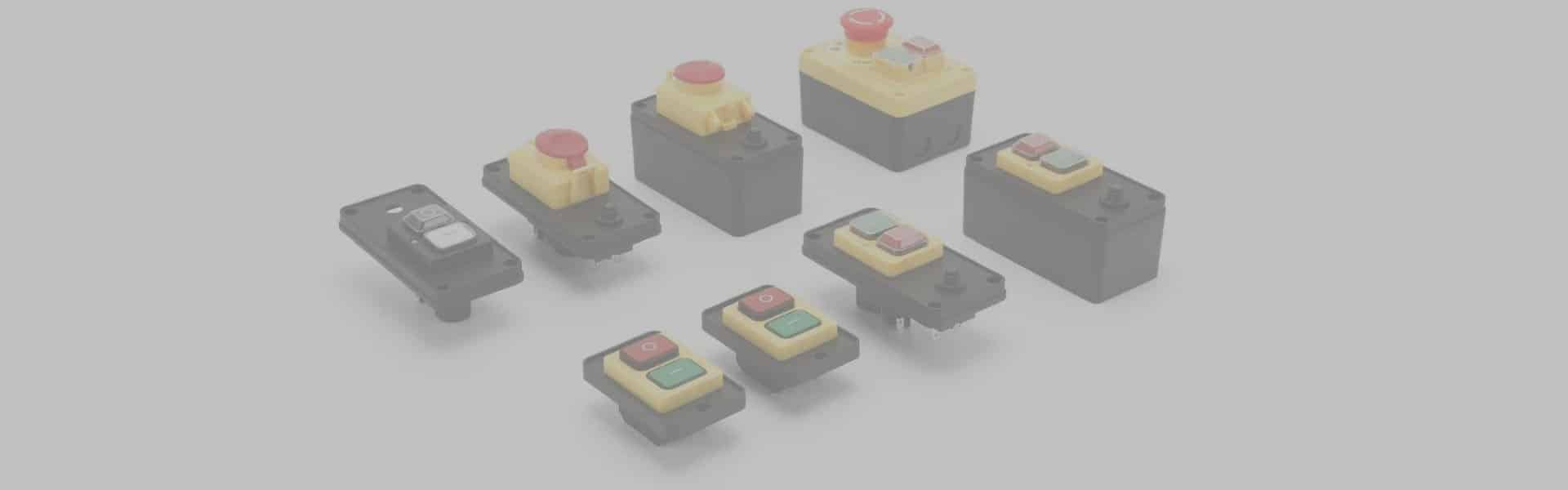

Electromagnetic push button switches are crucial components in dust collection systems for woodworking environments. Your high-quality switches help manage and control these systems efficiently, ensuring a safer and cleaner workspace. Here’s how your products can be applied and the benefits they bring:

Applications in Dust Collection Systems

- Control and Automation:

- Start/Stop Control: Your electromagnetic push button switches allow users to easily start and stop dust collection systems, providing straightforward control over the machinery.

- Emergency Stop: Your switches serve as reliable emergency stop buttons, enabling immediate shutdowns in case of a malfunction or emergency.

- Integration with Tools:

- Tool Activation: Your switches can be integrated to automatically activate the dust collection system when a woodworking tool is in use, enhancing operational efficiency.

- Sequencing:

- Sequential Operation: For larger systems, your switches facilitate the sequencing of multiple dust collectors and woodworking tools, ensuring synchronized operation and improved workflow.

Benefits of Electromagnetic Push Button Switches

- Enhanced Safety:

- Immediate Response: The quick response of your switches in emergency situations can prevent accidents and injuries, ensuring a safer working environment.

- Dust Control: Efficient dust collection, enabled by your switches, reduces respiratory risks and enhances overall safety in woodworking environments.

- Improved Efficiency:

- Reduced Downtime: Easy control and automation with your switches lead to reduced downtime, allowing workers to quickly start and stop the dust collection systems as needed.

- Energy Savings: Your automated systems ensure that the dust collection system operates only when necessary, resulting in significant energy savings.

- Durability and Reliability:

- Robust Design: Your electromagnetic push button switches are designed to withstand the harsh conditions of woodworking environments, including dust and vibrations.

- Long Lifespan: The durable construction of your switches ensures a long operational life, minimizing the need for frequent replacements.

Key Features of Your Switches

- Dust and Moisture Resistance: Your switches are rated for dust and moisture resistance, typically indicated by a high IP (Ingress Protection) rating.

- Ease of Installation: Your switches are designed for easy installation and integration with existing systems.

- Safety Certifications: Your switches meet relevant safety standards and certifications for industrial use, ensuring reliable and safe operation.

By incorporating your electromagnetic push button switches into their dust collection systems, woodworking operations can achieve better control, safety, and efficiency.

If you’re looking to enhance your dust collection systems, improve safety, and boost operational efficiency, contact us today. We can provide the high-quality switches you need to solve your related problems and improve your systems.