The Historical Evolution of Toggle Switch

Early Mechanical Switches

The history of the Toggle Switch can be traced back to the electrical revolution in the early 19th century. The earliest Toggle Switches were purely mechanical devices, usually consisting of a metal lever and simple contacts. These early switches were mainly used to control lighting systems and basic electrical equipment.

In 1917, Herbert H. Hubbell obtained an important patent for the Toggle Switch, a design that introduced an internal spring mechanism that allowed the switch to remain stably in the “on” or “off” position. This innovation laid the foundation for the modern Toggle Switch and promoted its widespread use in home and industrial environments.

Industrial Standardization Period

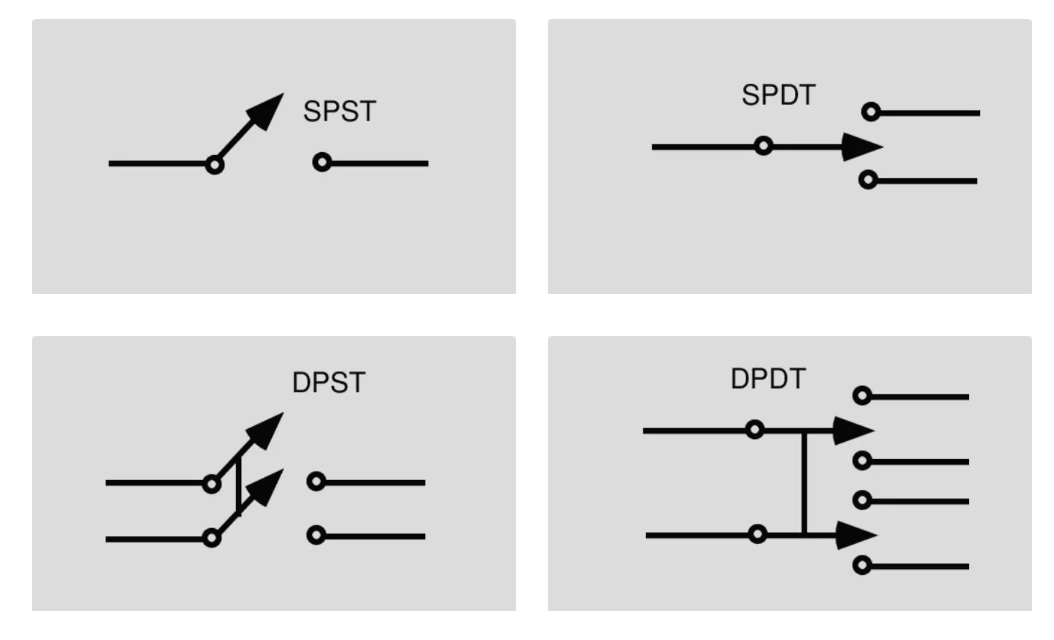

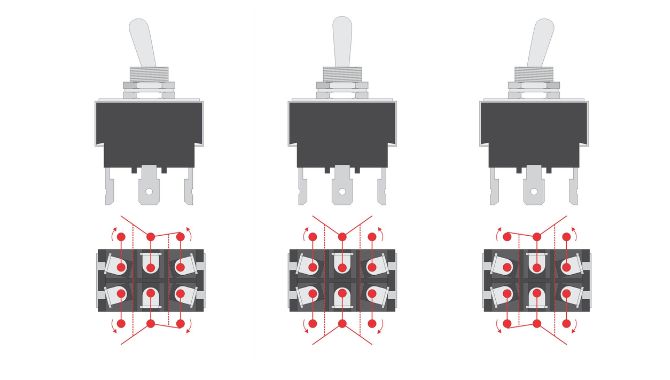

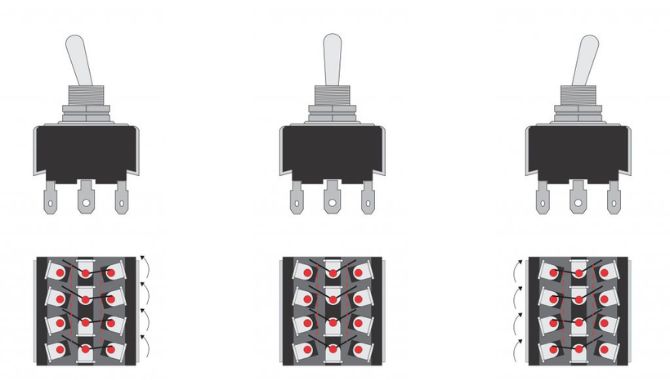

With the development of the electrical industry, the standardization of the Toggle Switch occurred in the mid-20th century. Various specifications and configurations were developed, including single-pole single-throw (SPST), single-pole double-throw (SPDT), double-pole single-throw (DPST), and double-pole double-throw (DPDT). This period also witnessed the emergence of miniature and subminiature Toggle Switches, and these miniaturized designs allowed the switch to be applied to more scenarios and devices.

Transformation in the Digital Age

With the rise of computers and digital technology, the Toggle Switch began to transform from a purely physical form to a digital interface element. The development of graphical user interfaces (GUIs) in the 1980s and 1990s introduced the concept of digital Toggle Switches, virtual switches that simulated the appearance and functionality of a physical Toggle Switch, but existed on a screen rather than in the physical world.

Modern Developments

Since the 21st century, both physical and digital Toggle Switches have undergone significant developments. Physical switches have made advances in materials, reliability, and protection levels, while digital Toggle Switches have continued to innovate in user experience, accessibility, and visual design.

Today, with the prevalence of the Internet of Things (IoT) and smart home technology, the line between physical and digital Toggle Switches has become increasingly blurred. Many modern Toggle Switches combine physical operation and digital control, such as smart switches that can be controlled by physical toggle or mobile apps.

What is Toggle Switch?

A toggle switch is a mechanical device that opens or closes an electrical circuit by moving a lever. The switch gets its name from its characteristic toggle action, which clearly indicates the “on” or “off” state. Toggle switches are ubiquitous in our daily lives and various technological applications, from simple home appliance controls to complex industrial equipment operations to user interaction elements in modern digital interfaces.

As technology develops, toggle switches have evolved from purely mechanical devices to important elements in digital interfaces. Today, when we talk about toggle switches, we may be referring to physical switches or switch controls in digital user interfaces. Although these two forms differ in appearance and implementation, their core function is the same: allowing users to switch between two mutually exclusive states.

Classification by electrical configuration

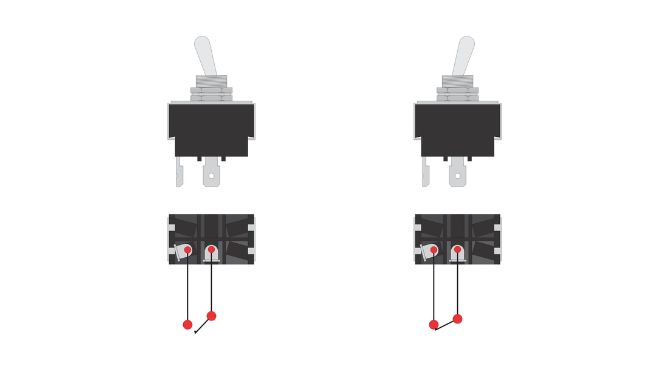

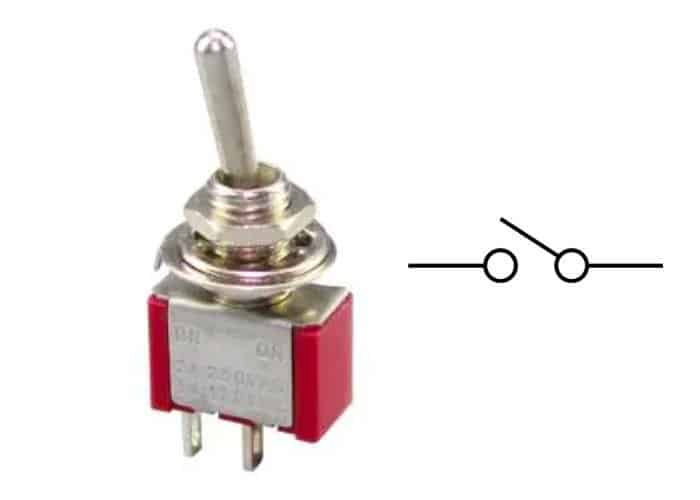

Single Pole Single Throw (SPST – Single Pole Single Throw)

The most basic type of Toggle Switch, with only one input and one output. It can connect or disconnect a single circuit, achieving a simple on/off function. Commonly seen in household light switches and simple electronic devices.

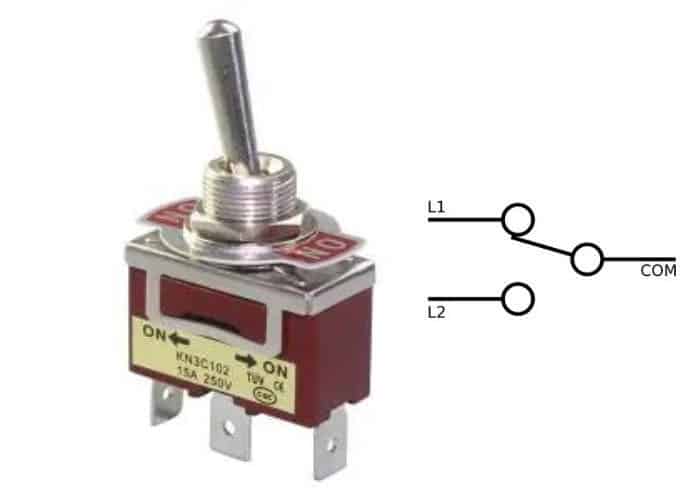

Single Pole Double Throw (SPDT – Single Pole Double Throw)

Has one input and two possible outputs. This switch allows a single input to be connected to one of two different outputs, often used to select switching between two power or signal paths.

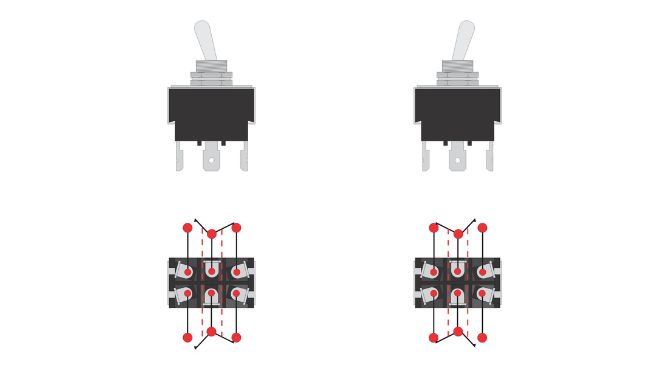

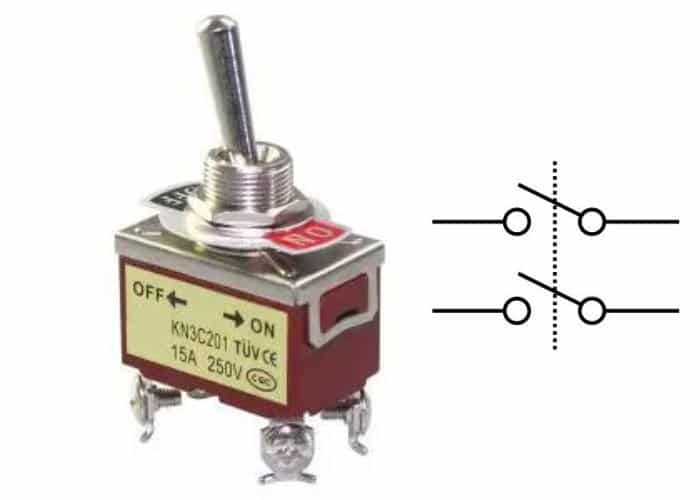

Double Pole Single Throw (DPST – Double Pole Single Throw)

A switch that controls two independent circuits at the same time. When the lever is flipped, the two circuits are connected or disconnected at the same time. This type is often used in scenarios where two independent circuits need to be controlled at the same time.

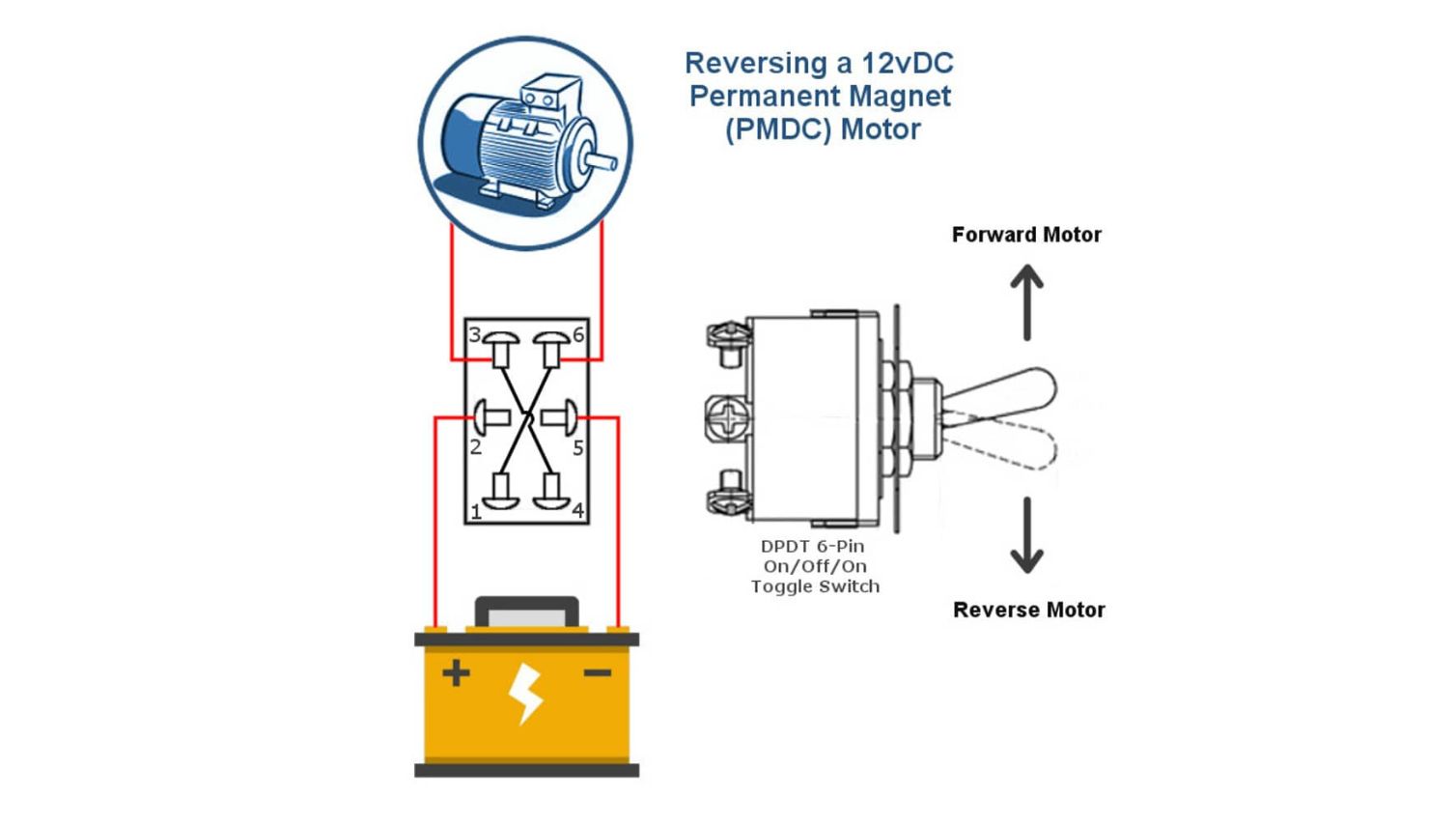

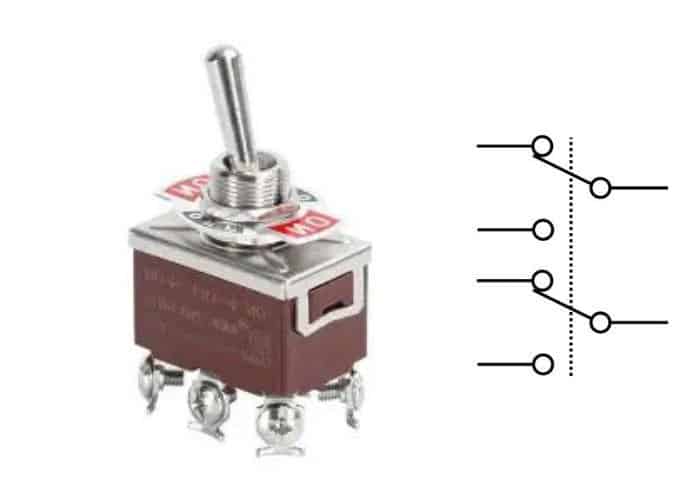

Double Pole Double Throw (DPDT – Double Pole Double Throw)

The most complex common type of Toggle Switch, with two inputs, each of which can be connected to one of two possible outputs. This switch is often used in motor reversing control or complex circuit switching scenarios.

Classification by operation mode

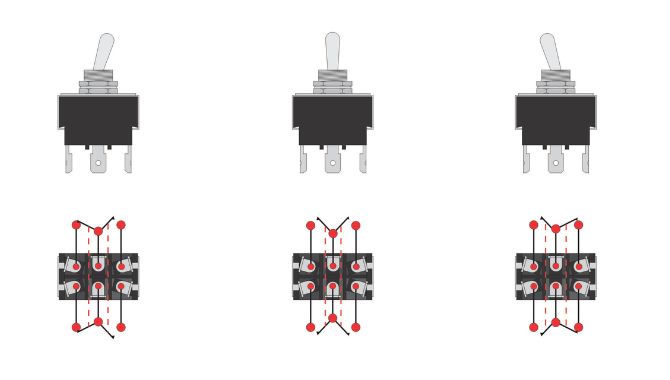

Maintained Switch

This type of Toggle Switch will remain in its new position after being moved until it is moved again. Most household light switches are maintained, and will remain on after being moved to the “on” position until they are moved back to the “off” position.

Momentary Switch

This type of Toggle Switch changes state only when it is operated, and will automatically return to its default position after it is released. Momentary Toggle Switches are often used in scenarios where a function needs to be temporarily activated, such as the talk button on an intercom.

Toggle switch by size

Standard size:

Traditional Toggle Switch size, commonly found in industrial equipment and older appliances.

Miniature:

A Toggle Switch that is smaller than the standard size, suitable for applications where space is limited.

Subminiature:

An even smaller Toggle Switch, commonly used in electronic equipment and precision instruments.

Ultra-subminiature:

The smallest Toggle Switch type, designed for applications with extremely limited space.

How Physical Toggle Switches Work

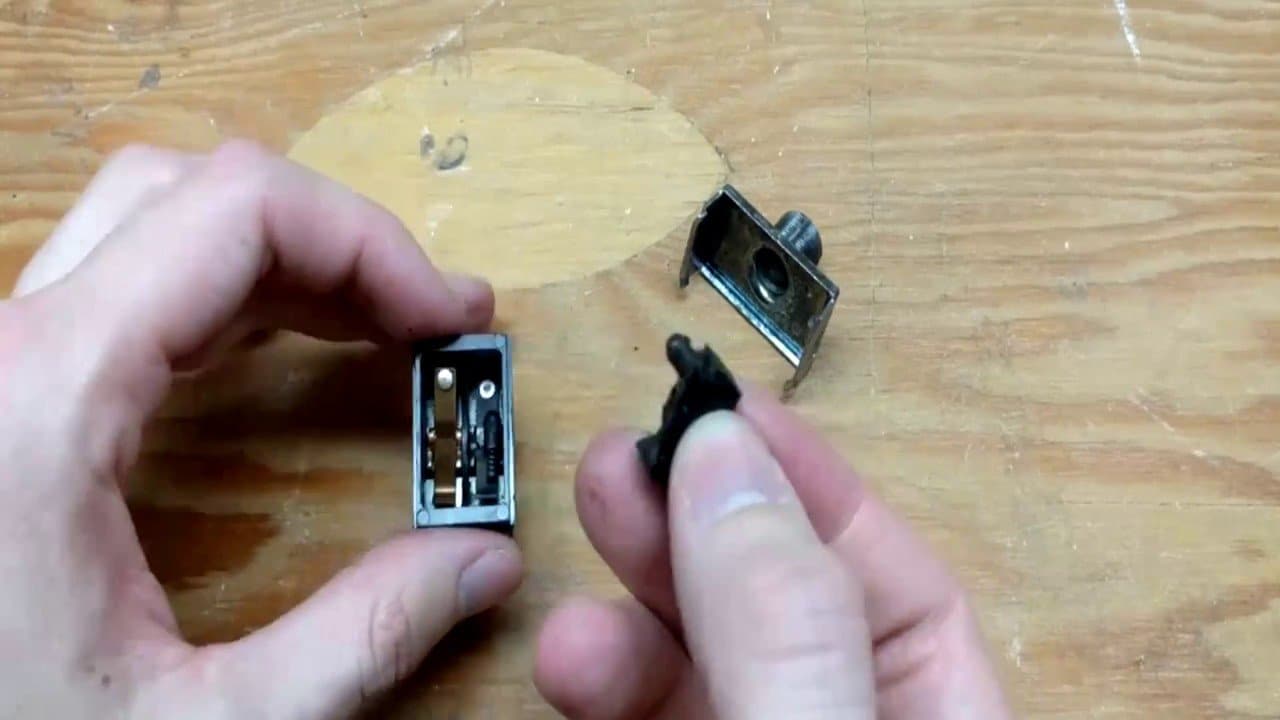

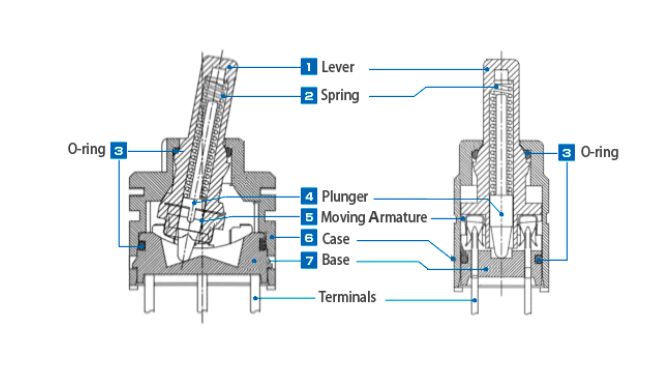

The working principle of a physical toggle switch is based on a simple and reliable mechanical structure. A typical toggle switch contains the following core components:

1. Lever/handle: The external part that the user operates, usually made of plastic or metal.

2. Spring mechanism: Provides tactile feedback and helps the switch stay in a specific position.

3. Contacts: The metal part that actually completes or breaks the circuit, usually made of conductive materials such as copper, silver or gold.

4. Housing: The structure that protects the internal components and provides mounting support.

When the user flips the lever, the internal mechanism moves, causing the contacts to contact or separate, thereby completing or breaking the circuit. In a maintained toggle switch, the spring mechanism helps the switch stay in the new position, while in a momentary toggle switch, the spring pulls the switch back to the default position after release.

Sub-Mini Toggle Switch

Rating: 3A 125VAC; 1.5A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1000VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥10,000 Cycles

Miniature Toggle Switch

Rating: 6A 125VAC; 3A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1500VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥10,000 Cycles

Medium Toggle Switch

Rating: 10A 125VAC; 6A 250VAC

15A 125VAC; 10A 250VAC

20A 125VAC; 15A 250VAC

Contact Resistance: 20mΩ max

Insulation Resistance: 500VDC 1000MΩ min

Dielectric strength: 1500VAC, 1 Minute

Operating Temperature: -25℃ to +85℃

Electrical Life: ≥10,000 Cycles

Why use safety covers for toggle switches?

Safety covers for toggle switches prevent accidental activation, ensuring operational safety and reliability. Our covers are made from high-quality, durable materials, offering superior protection and longevity. As a leading switch in China, we provide customizable designs to meet specific needs. Trust our expertise for innovative, reliable solutions. Click here to learn more!

toggle switch waterproof cover

Our toggle switch waterproof covers provide robust protection against water and dust, ensuring reliable performance in harsh conditions. Manufactured in China, we guarantee high-quality materials and precise engineering. Our covers are easy to install, durable, and compatible with various switch models. Choose our products for superior security and longevity of your electrical components.

Toggle Switch Panel

Our high-quality toggle switch panel, designed and manufactured in China, offers exceptional durability and precision. With a sleek design, it ensures reliable performance for various applications. Key features include easy installation, robust construction, and long-lasting materials. Choose our products for competitive pricing, excellent customer service, and superior craftsmanship. Click to learn more!

SPST Toggle Switch

A Single Pole Single Throw (SPST) Toggle Switch is a basic on/off switch used in various electrical applications. Our switches are manufactured with high-quality materials ensuring durability and reliability. We provide customizable options, competitive pricing, and fast delivery. Ideal for automotive, industrial, and household use, our switches meet international safety standards. Click to view more!

DPDT Toggle Switch

A DPDT Toggle Switch is a versatile switch that can control two separate circuits, allowing for dual on/off functionality. Our switches are renowned for their durability, precision, and reliability, ensuring seamless performance in various applications. Manufactured in China with high-quality materials, our products meet international standards and offer competitive pricing. Click to explore our robust, user-friendly designs!

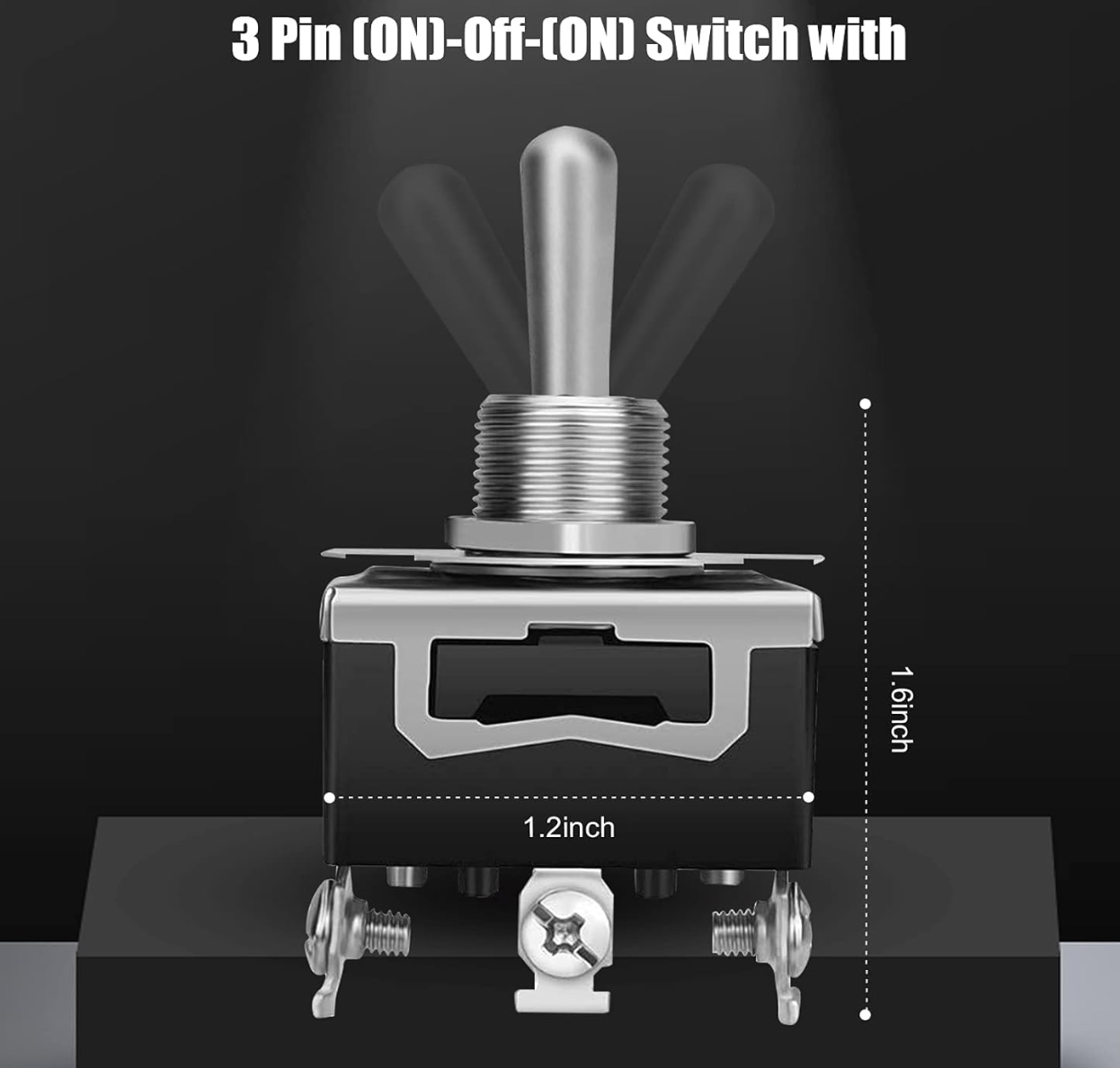

ON OFF ON Toggle Switch

The ON OFF ON Toggle Switch is a durable, high-quality switch designed for reliable performance in various applications. Manufactured with premium materials, it ensures longevity and safety. Our switches offer smooth operation, clear markings, and robust construction. Choose our products for their precision engineering, competitive pricing, and exceptional customer support. Click to learn more about our innovative solutions.

Momentary Toggle Switch

Our momentary toggle switches are designed for reliability and precision. They activate circuits only while being pressed, ensuring efficient control in various applications. Manufactured with high-quality materials, our switches offer durability and excellent tactile feedback. With customizable options and competitive pricing, we provide the best solutions for your switching needs.

-Toggle-Switch.jpg)

ON OFF(ON) Toggle Switch

Our ON OFF(ON) Toggle Switch ensures reliable performance and durability, designed to meet your specific needs. Featuring a robust construction, it handles high current loads with ease. Our switches are easy to install, offering smooth operation and long-lasting service. Choose us for top-quality manufacturing, competitive pricing, and exceptional customer support. Click to explore more!

4PDT Toggle Switch

Our 4PDT (Four Pole Double Throw) toggle switch offers robust functionality, allowing control over four separate circuits. Manufactured in China with precision engineering, our switches ensure reliability, durability, and excellent performance. Ideal for various applications, they feature a sturdy design, high-quality materials, and easy installation. Choose us for competitive pricing and superior customer support.

How to Wire a Toggle Switch?

A toggle switch is an electrical switch that opens and closes an electrical circuit by moving a lever back and forth. Our high-quality toggle switches feature rugged construction, long-lasting performance, and easy installation. Carefully manufactured in China, they are ideal for a variety of applications, ensuring reliable, efficient operation. Click to explore our extensive product line and find the toggle switch wiring method that meets your needs.

How Does a Toggle Switch Work?

A toggle switch operates through a simple yet elegant mechanism. When you manipulate the external lever, you’re actually controlling two internal contacts. In the ‘off’ position, the contacts remain open, blocking the passage of electricity. Flip the lever to ‘on’, and you’ll close those contacts, forming a complete circuit that energizes your system. This binary operation is fundamental, whether you’re switching on a light or integrating a switch into complex industrial machinery.

Buying Guide for Toggle Switches?

Selecting the right Toggle Switch is critical to ensuring the functionality, usability, and reliability of a device or interface. Here are the key considerations when selecting physical and digital Toggle Switches:

Electrical requirements

Current and voltage ratings: Make sure the switch can safely handle the current and voltage of the circuit.

Contact configuration: Select the appropriate configuration (SPST, SPDT, DPST, DPDT, etc.) based on the circuit requirements.

Electrical life: Consider the life of the switch under the expected load.

Special requirements: Special electrical performance requirements such as low contact resistance and high insulation resistance.

Mechanical requirements

Size and mounting method: Make sure the switch fits the installation space and mounting method (panel mount, PCB mount, etc.).

Operation type: Choose maintained or momentary, depending on the application requirements.

Operation force and feel: Consider the requirements for operation force and feel for the target user and usage scenario.

Mechanical life: Evaluate the number of operations the switch needs to withstand.

Environmental factors

Temperature range: Make sure the switch can operate normally in the expected ambient temperature range.

Protection level: Select the appropriate IP protection level based on environmental conditions.

Vibration and shock resistance: In environments with vibration or shock, choose switches with corresponding resistance.

Chemical resistance: In environments with chemicals, choose switches with appropriate materials.

Safety and certifications

Safety standards: Make sure the switch meets relevant safety standards and regulations.

Industry certifications: Choose switches with appropriate certifications (such as UL, CSA, VDE, etc.) depending on the application area.

Special requirements: Some applications may require explosion-proof, fire-proof or other special safety features.

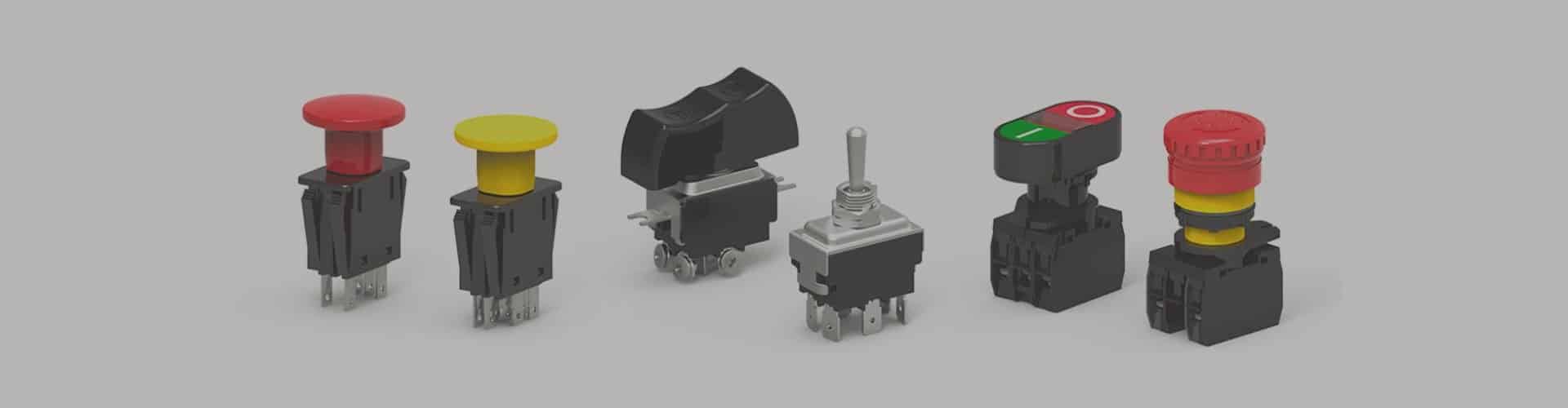

Types of Toggle Switches

These are basic on-off switches with one pole (input) and one throw (output). They are used in simple electrical circuits where only two states are required: open or closed. An example is a light switch that turns a light on or off.

SPDT toggle switches have one pole but two throws, allowing the user to choose between two separate outputs. These switches are commonly used for switching between different power sources or selecting different modes in electronic devices.

DPST toggle switches have two poles and one throw for each pole. These are essentially two SPST switches Acombined into a single component. They can control two separate circuits simultaneously and are commonly used when both circuits need to be switched at the same time.

DPDT toggle switches have two poles and two throws for each pole. They function like a combination of two SPDT switches and allow users to control and switch between two separate pairs of circuits simultaneously.

An “on-off-on” toggle switch is a type of toggle switch that provides three positions: two of which are “on” positions, and one that is the “off” position. These switches are often used in applications where a device or system needs to be controlled in multiple ways or where different functions are required.

Momentary toggle switches return to their original position after being activated by the user. They only maintain contact while being held in position, making them suitable for applications where temporary activation is required, such as starting an engine or triggering an event in electronic devices.

Waterproof toggle switch is a type of toggle switch designed to resist the ingress of water or other liquids. These switches are commonly used in applications where exposure to moisture or liquids is a concern, such as in marine environments, outdoor settings, or industrial applications where equipment may be exposed to water.

toggle switch cover is a protective accessory that is designed to encase and shield a toggle switch. These covers serve several purposes, including enhancing safety, preventing accidental activation or deactivation of the switch, and providing additional protection against environmental elements. Toggle switch covers come in various designs and styles to accommodate different applications and user preferences.

Lighted toggle switches incorporate small LED lights within the switch mechanism to provide visual feedback about their current state. This makes it easy for users to know whether a circuit is active or not and can be especially helpful in low-light environments.

These switches have smaller external size and internal components, making them suitable for compact devices and applications with space limitations. Despite their reduced size, they still offer a variety of contact ratings and electrical life.

Genetic toggle switches are specialized gene circuits used in synthetic biology to create continuous, non-linear biochemical control networks. They utilize stochastic mechanisms to control gene expression levels, enabling the precise regulation of cellular processes.

Related Product

As a simple yet powerful control mechanism, the Toggle Switch has evolved from its original mechanical electrical switches to become an essential element in modern digital interfaces. Their persistence and ubiquity are a testament to the value of good design—intuitive, reliable, and easy to use.

Whether in physical or digital form, the Toggle Switch embodies the same core principles: providing a clear binary choice and communicating the current state through intuitive visual and tactile feedback. This simplicity has made the Toggle Switch an indispensable component in a wide range of applications, from home appliances to industrial equipment, from mobile apps to website interfaces.

As technology continues to develop, the Toggle Switch will continue to evolve, incorporating new materials, new technologies, and new interaction modes. However, its basic functionality and user experience principles are likely to remain relatively stable because they are based on the basic human understanding of binary choices and interaction needs.

When designing and selecting a Toggle Switch, it is important to consider technical requirements, user needs, environmental factors, and sustainability. By considering these factors comprehensively, you can ensure that the Toggle Switch not only functions properly, but also provides an excellent user experience and has minimal impact on the environment.

Whether you are an engineer, designer, or ordinary user, understanding how the Toggle Switch works, its types, and best practices can help you create and use better products and interfaces. In this increasingly digital and connected world, Toggle Switch will continue to play an important role as a basic element of human-computer interaction.

FAQs

Toggle Switches are commonly used in various applications, and people often have questions about them. Here are five of the most popular FAQs for Toggle Switches:

Toggle switches are widely used in various applications, including automotive controls, industrial machinery, home appliances, and electronic devices. They are favored for their simplicity and reliability in controlling electrical circuits.

oggle switches are commonly made from durable materials like metal, plastic, or a combination of both. The internal contacts are often made of copper or silver to ensure good conductivity and long-lasting performance.

Yes, there are waterproof and weatherproof toggle switches designed for use in harsh environments, such as outdoor or marine applications. These switches are typically sealed to prevent water and dust from entering the internal components, ensuring reliable operation even in challenging conditions.

Choosing the right toggle switch depends on several factors, including the required voltage and current ratings, the number of poles and throws, the operating environment, and whether you need additional features like waterproofing or illumination. It’s important to match the switch’s specifications with the requirements of your application.

Yes, many s offer customization options for toggle switches, such as different actuator styles, terminal types, and additional features like LED indicators. Customization ensures that the switch meets the specific needs of your application.

oggle switches offer several advantages, including ease of use, reliability, durability, and the ability to control circuits with a simple flip of a lever. They are also available in various configurations, making them versatile for different applications.

Toggle switches require minimal maintenance. However, regular inspections for signs of wear or damage, especially in harsh environments, are recommended. Ensure that the switch and its connections are clean and free from corrosion to maintain optimal performance.