DPDT (Double Pole Double Throw) marine rocker switches are a type of electrical switch commonly used in marine environments due to their reliability, durability, and ability to handle the specific requirements of marine applications. Here’s a comprehensive understanding of DPDT marine rocker switches:

Basic Structure and Function

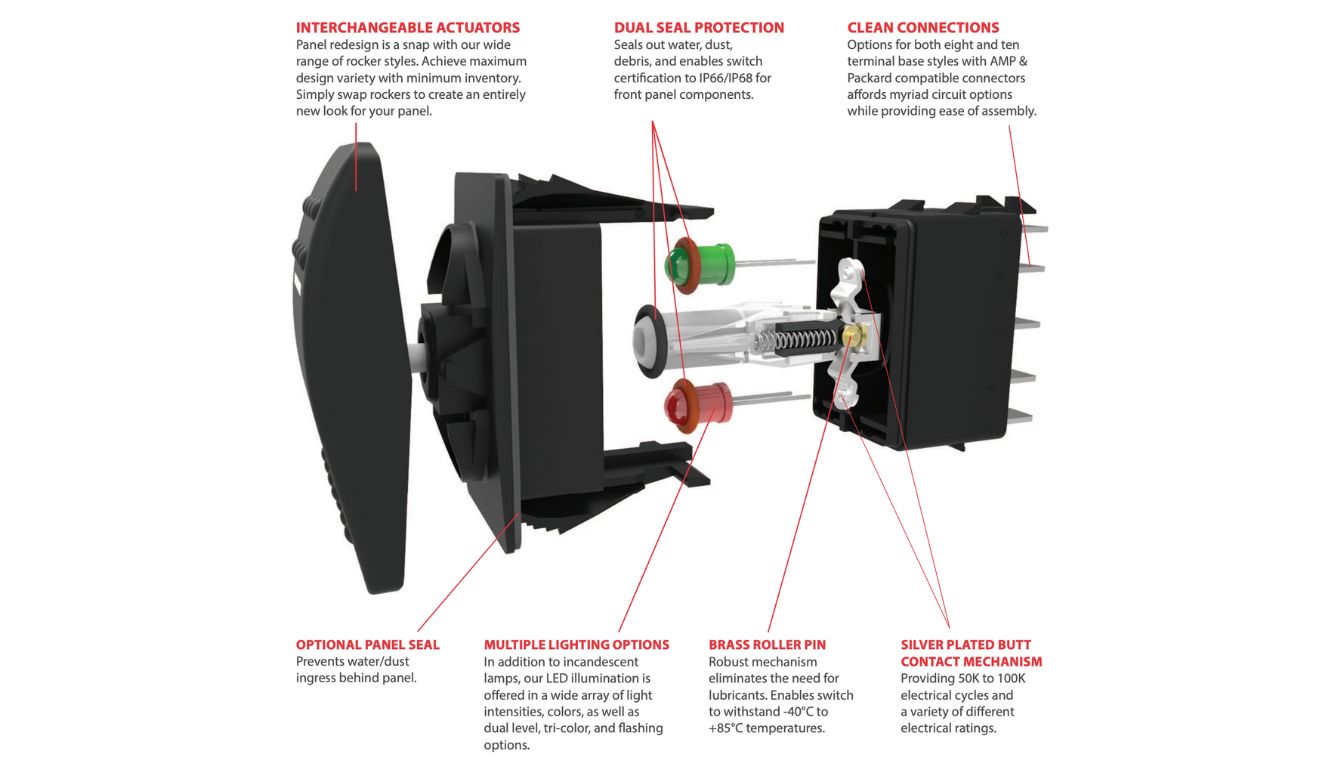

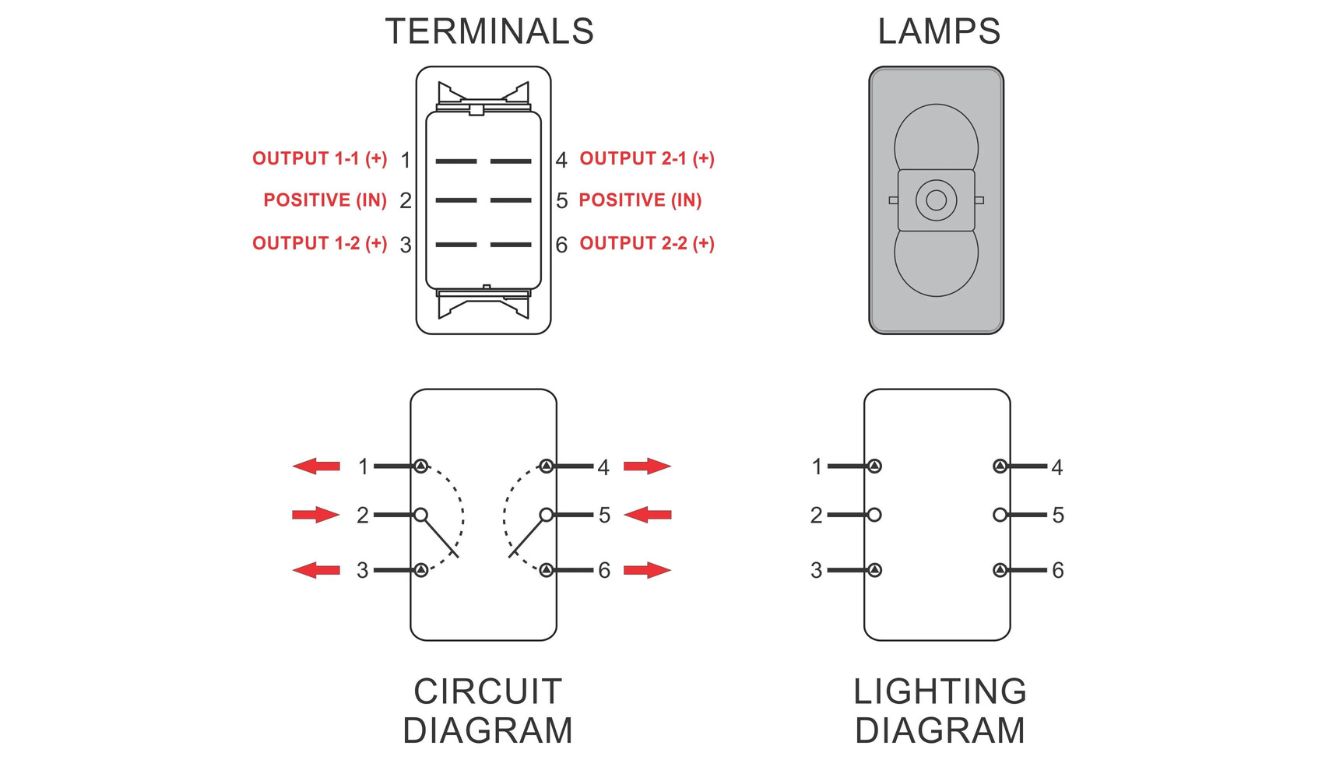

- Double Pole Double Throw (DPDT): This refers to the switch’s configuration, which has two sets of contacts (poles) that can each be thrown (connected) to two different positions. This allows for more complex switching operations, such as reversing motors or controlling two circuits simultaneously.

- Rocker Switch: A rocker switch is a type of switch where the actuator is a rocker arm that can be pressed in two directions. This design makes it easy to operate, even with gloves or in difficult environments.

Key Features of DPDT Marine Rocker Switches

- Durability: Marine environments are harsh, with exposure to saltwater, humidity, and temperature extremes. DPDT marine rocker switches are designed to withstand these conditions, often featuring waterproof and corrosion-resistant materials.

- Reliability: These switches are engineered to maintain stable performance over extended periods, even under heavy use. They typically have a long mechanical and electrical life cycle, ensuring reliable operation.

- Safety: Marine safety standards are stringent. DPDT marine rocker switches often comply with international safety standards, such as IP66 or IP68 ratings, which indicate a high level of dust and waterproof protection.

- Versatility: DPDT marine rocker switches come in various configurations, including different current and voltage ratings, LED indicators, and mounting options. This allows them to be used in a wide range of marine applications.

Common Applications

- Navigation Lighting: Controlling navigation lights on boats and ships.

- Engine Controls: Switching between engine functions, such as starting, stopping, and reversing.

- Electrical System Management: Managing electrical circuits, such as power distribution and battery charging systems.

- Auxiliary Equipment: Controlling auxiliary equipment like pumps, winches, and other machinery.

Selection and Installation Considerations

- Rating: Choose a switch with the appropriate current and voltage ratings for the specific application. Overloading a switch can lead to failure or safety hazards.

- Environment: Consider the specific environmental conditions, such as saltwater exposure, humidity, and temperature extremes. Select a switch with the appropriate protection ratings (e.g., IP66 or IP68).

- Mounting: Ensure the switch is properly mounted and securely fastened to prevent movement or vibration, which could affect performance or cause damage.

- Compliance: Check that the switch complies with relevant safety standards and regulations for marine use.

Maintenance and Troubleshooting

- Regular Inspection: Periodically inspect the switch for signs of wear, corrosion, or damage.

- Cleaning: Keep the switch clean and free of debris, particularly saltwater, which can cause corrosion.

- Testing: Regularly test the switch’s functionality to ensure it operates correctly.

- Troubleshooting: If the switch fails, consult the manufacturer’s documentation for troubleshooting tips or contact a qualified technician for assistance.

Examples of DPDT Marine Rocker Switches

Several manufacturers offer DPDT marine rocker switches, such as Littelfuse, which has a range of sealed rocker switches suitable for marine applications. These switches are available with different current and voltage ratings, LED illumination options, and mounting styles.

Conclusion

DPDT marine rocker switches are essential components in marine electrical systems. Their durability, reliability, and versatility make them well-suited for the harsh marine environment. When selecting and installing these switches, it’s important to consider the specific requirements of the application and ensure compliance with relevant safety standards and regulations. Regular maintenance and troubleshooting will help ensure the continued reliable operation of these critical components.