How to Choose a High-Quality Toggle Switch for Your Application

Choose high-quality toggle switches for reliability and performance. Our switches feature durable materials, smooth operation, and excellent electrical conductivity. With customizable options, we cater to diverse applications, ensuring safety and longevity. As a leading in China, we offer competitive pricing, rigorous testing, and fast delivery. Trust our expertise to enhance your projects with superior toggle switches. Click to learn more!

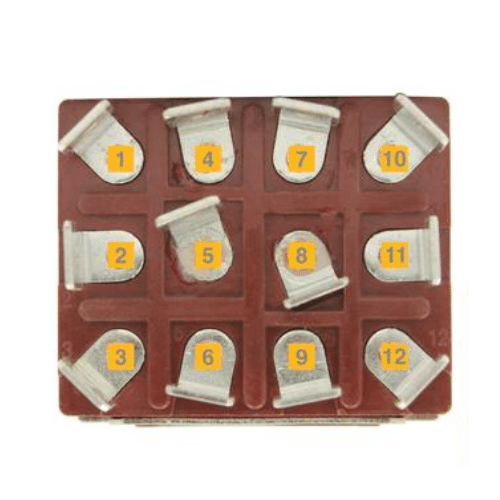

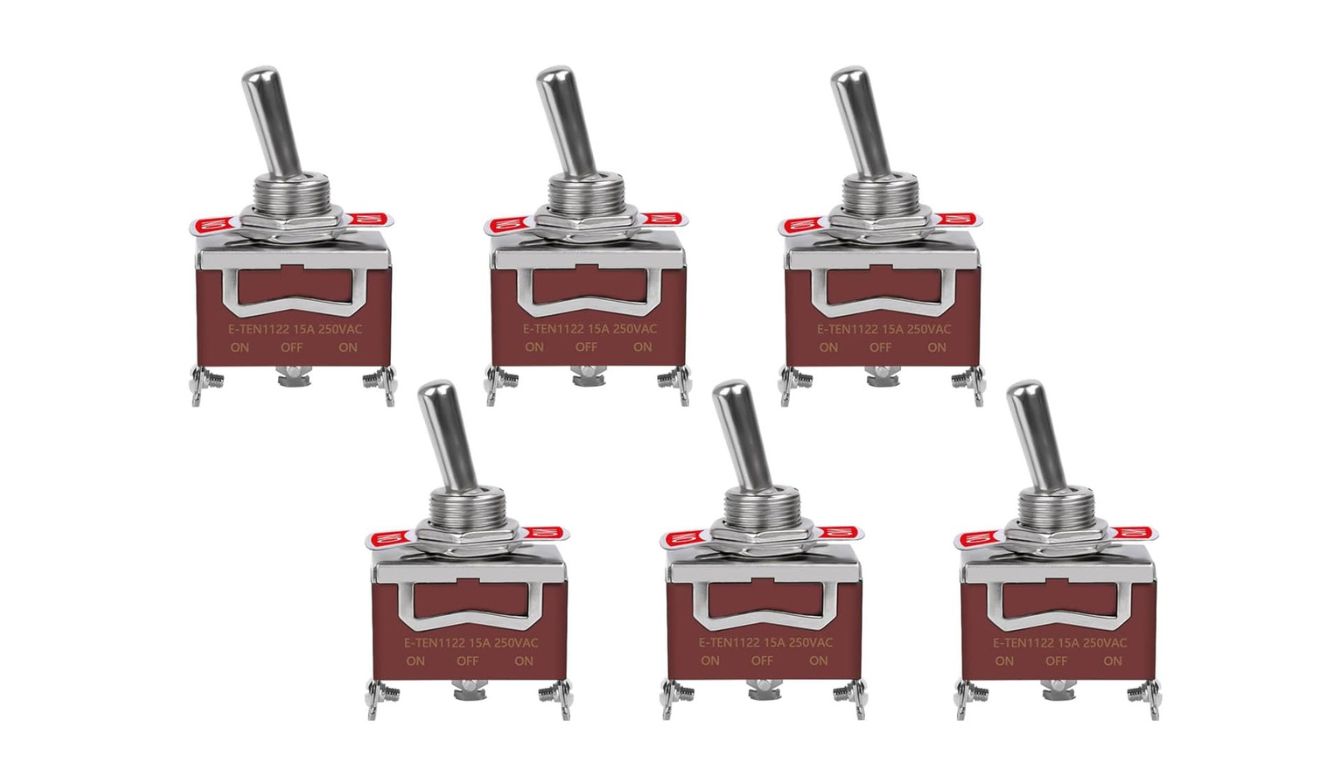

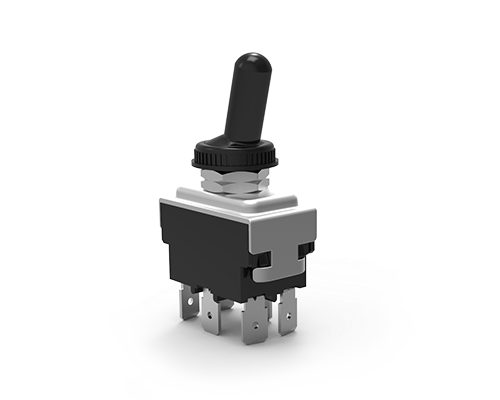

Medium Toggle Switch

Our medium toggle switches are designed for durability and precision, ensuring reliable performance in various applications. Manufactured in China with high-quality materials, our switches offer smooth operation and long-lasting functionality. Key features include robust construction, easy installation, and a sleek design. Choose us for competitive pricing, excellent quality control, and prompt customer service.

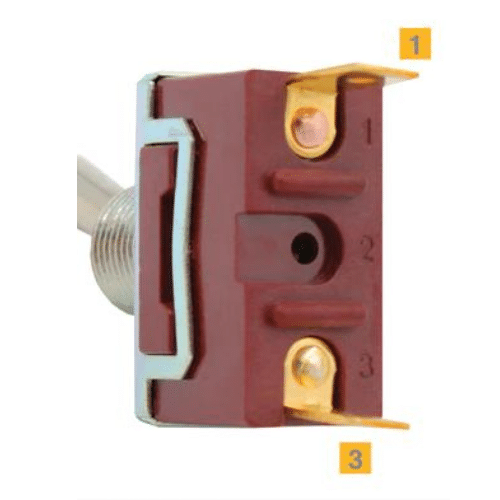

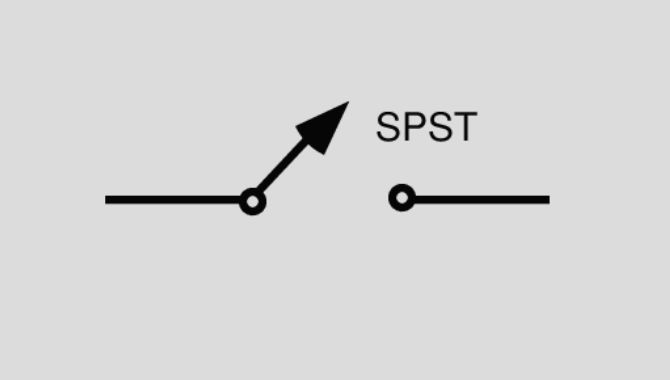

Toggle Switch SPST On-Off

Toggle Switch SPST (On)-Off

Toggle Switch SPST On-(Off)

Toggle Switch SPST On-Off

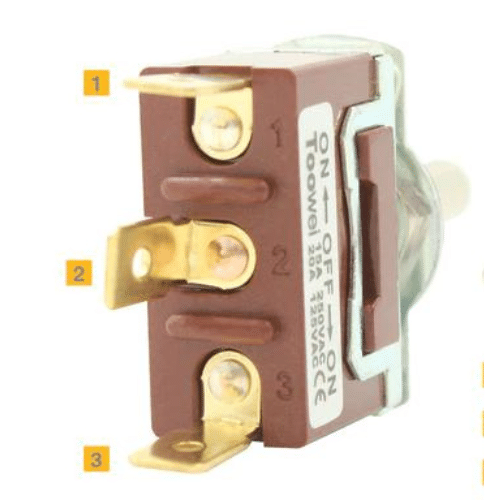

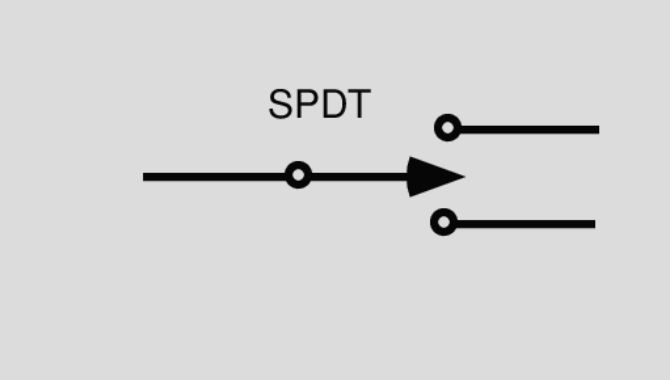

Toggle Switch SPDT On-Off-On

Toggle Switch SPDT On-Off

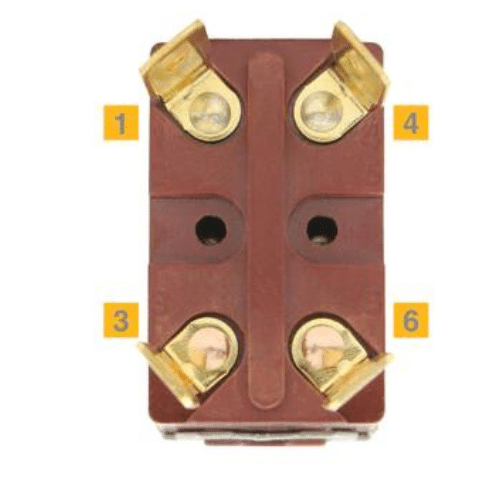

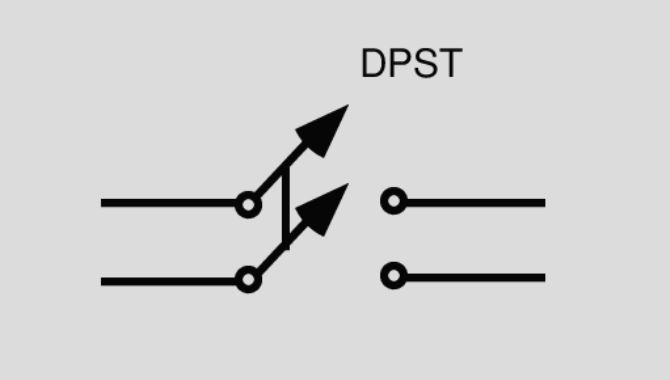

Toggle Switch DPST On-Off

Toggle Switch DPST (On)-Off

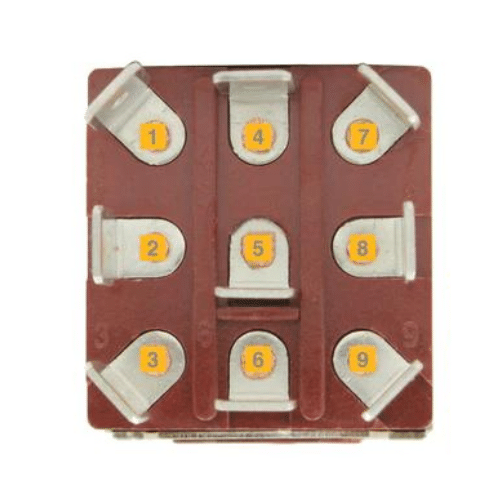

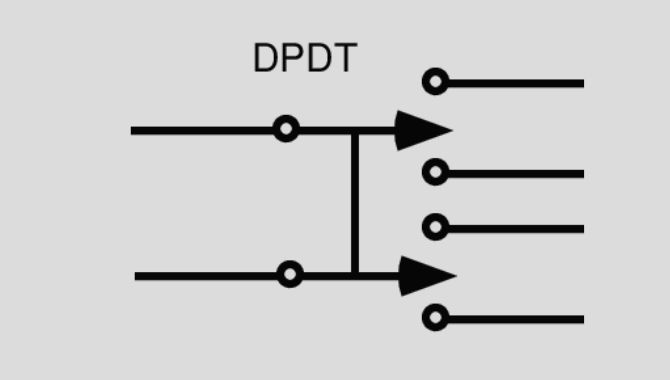

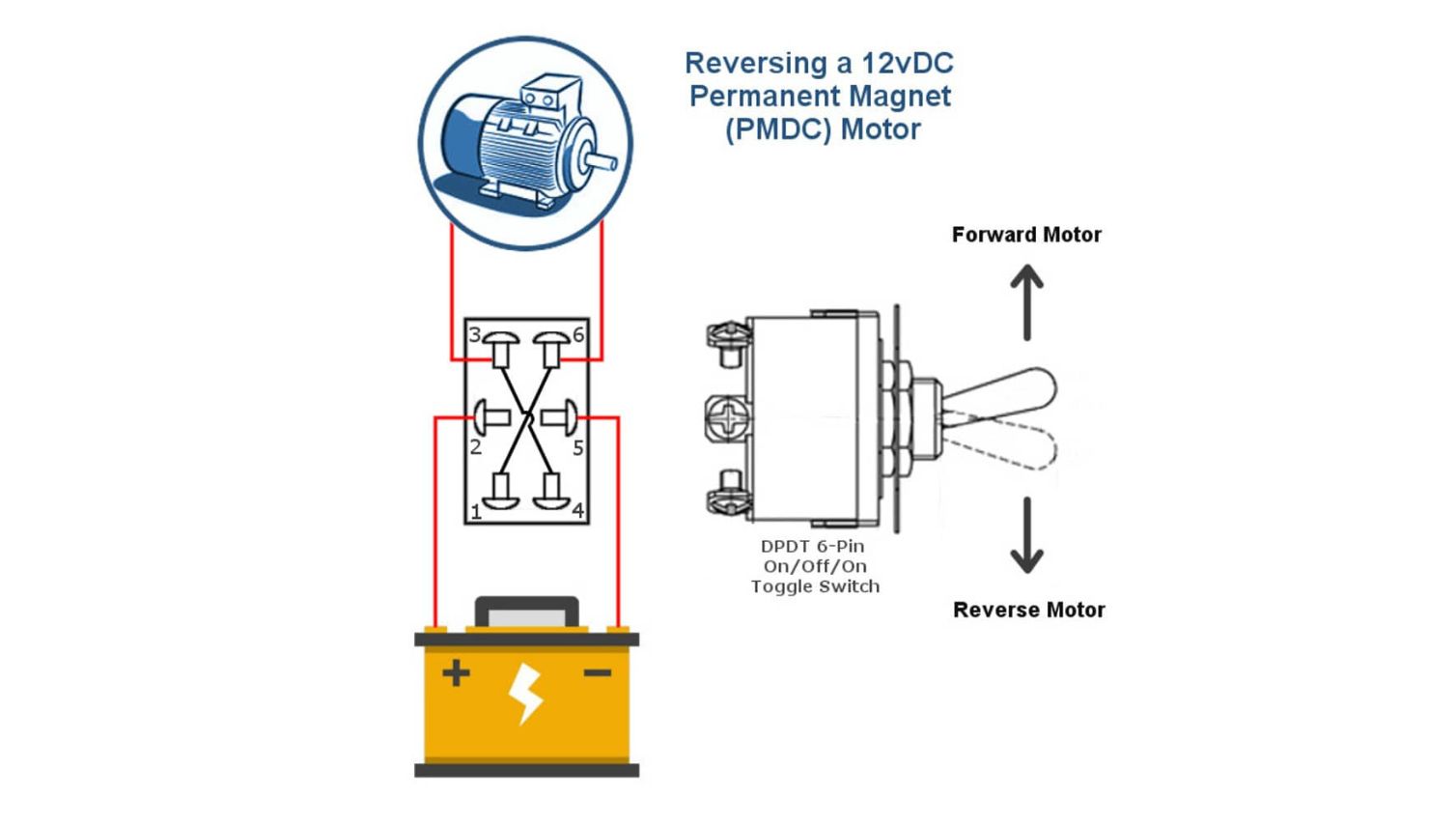

Toggle Switch DPDT On-Off-On

Toggle Switch DPDT On-On

Toggle Switch DPDT (On)-Off-(On)

Toggle Switch Cover

- Flip-up covers that must be lifted before accessing the toggle

- Boot covers that allow operation while providing environmental protection

- Safety covers that require deliberate action to access the switch

Yellow Toggle Switch Cover

Purple Toggle Switch Cover

Blue Toggle Switch Cover

Red Toggle Switch Cover

Gray Toggle Switch Cover

White Toggle Switch Cover

Black Toggle Switch Cover

Green Toggle Switch Cover

Carbon Fiber Toggle Switch Cover

Transparent Blue Toggle Switch Cover

Transparent Red Toggle Switch Cover

Transparent Green Toggle Switch Cover

Transparent Yellow Toggle Switch Cover

Transparent White Toggle Switch Cover

Toggle Switch Cover

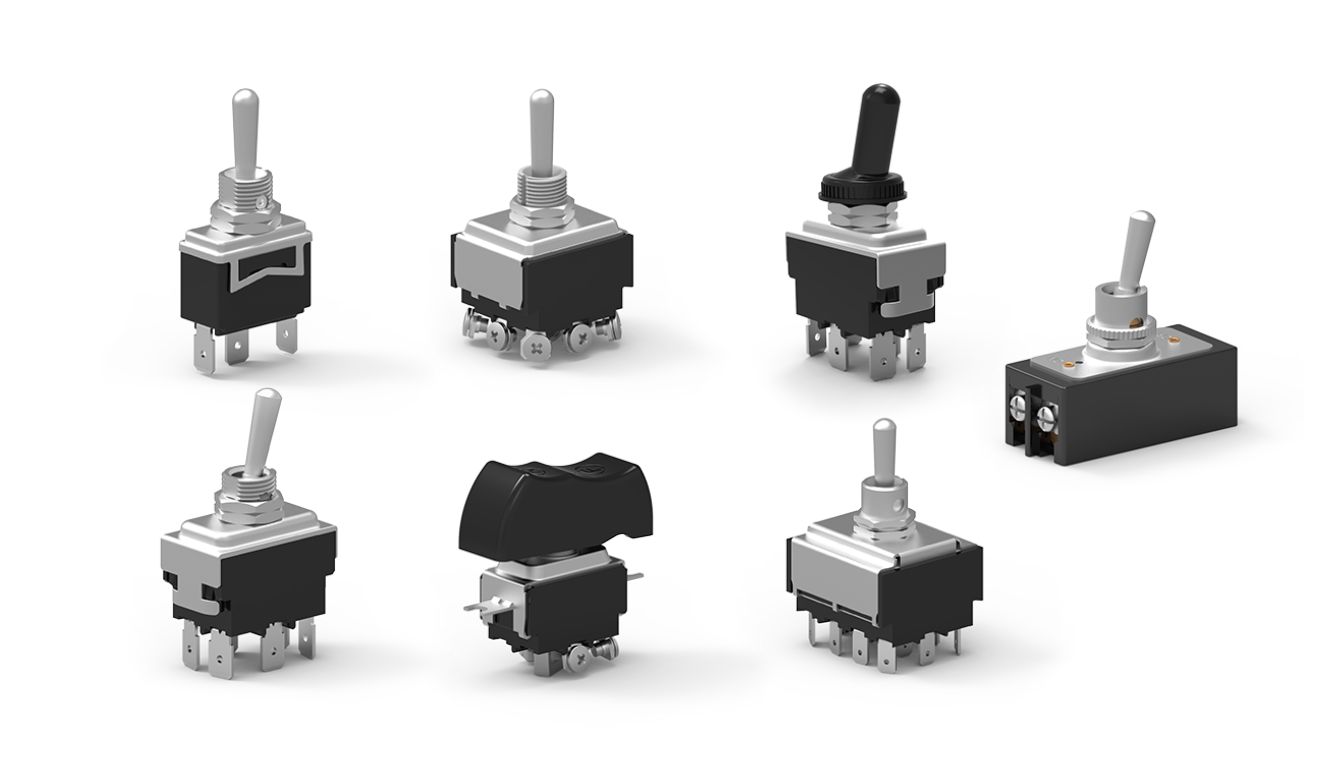

Classification by Pole & Throw Configuration

Toggle switches are essential electrical components used to control circuits. Our offerings include SPST (Single Pole Single Throw), SPDT (Single Pole Double Throw), DPST (Double Pole Single Throw), and DPDT (Double Pole Double Throw) switches.

Advantages of our products include high durability, reliable performance, and customizable designs. Manufactured with quality materials, our switches ensure long-lasting operation in various applications. Explore our range for innovative solutions that meet your needs!

With Full Product Certification

What are Toggle Switches?

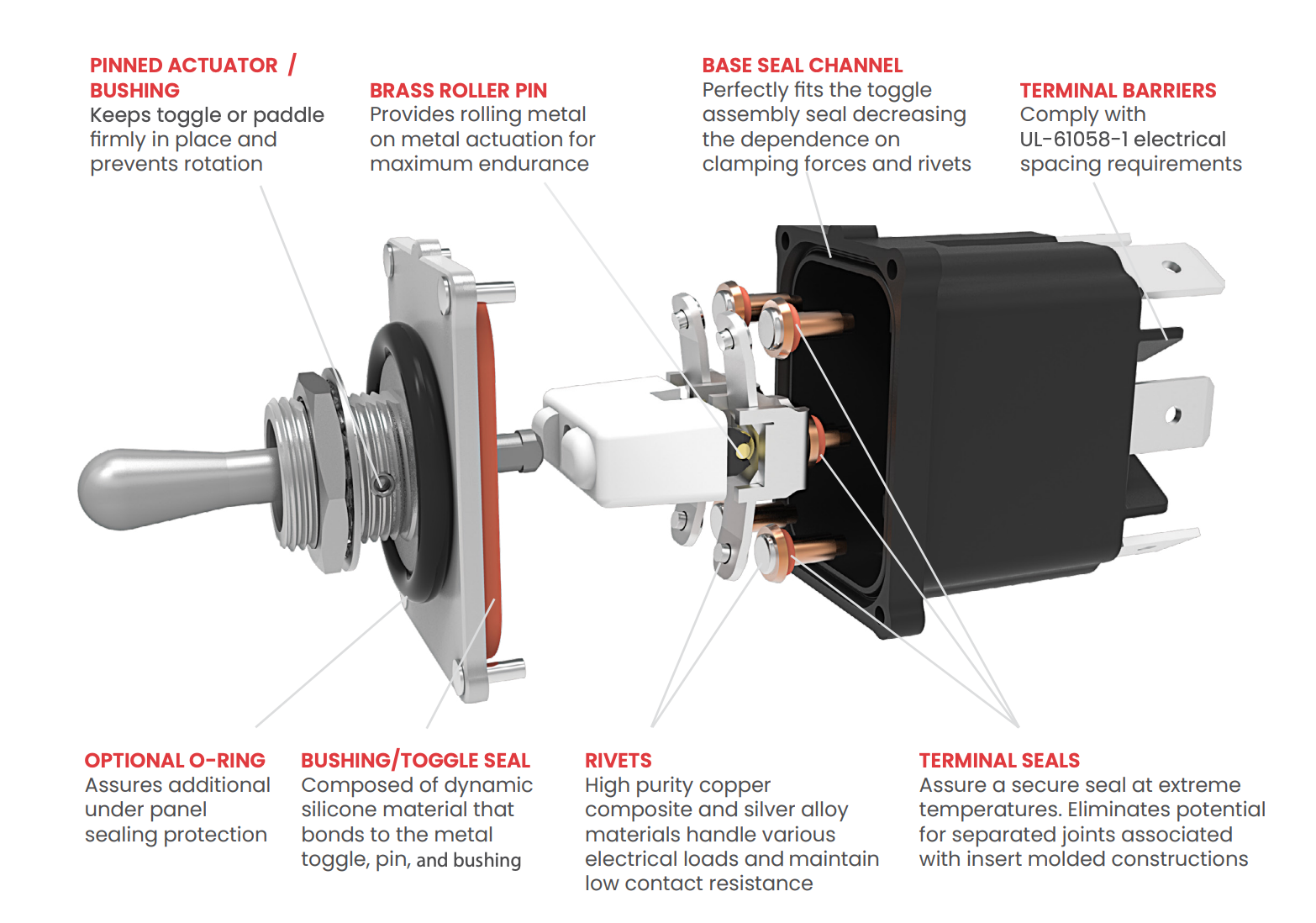

- Actuator (Lever or Handle): The external part that users manipulate to change the switch position. This lever typically pivots around a central point and can be moved between two or more positions.

- Contacts: The internal metal components that either connect or disconnect to complete or break the electrical circuit. These contacts are typically made from conductive metals like brass, copper, or silver, often plated with gold or nickel for better conductivity and corrosion resistance.

- Housing: The protective casing that contains the internal components and provides structural support. Housing materials vary depending on the application, with options including plastic, metal, or specialized materials for harsh environments.

How Do Toggle Switches Work?

The lever or handle of the switch is moved by the user, which in turn moves a contact point between two positions: one that completes the circuit and allows current to flow (on), and another that breaks the circuit and stops the current flow (off).

Why Choose WEUP as Your Trusted Toggle Switch Manufacturer?

Selecting the right toggle switch is a decision that extends far beyond a simple component purchase; it’s about forging a partnership with a supplier who understands your technical challenges, quality imperatives, and market demands. WEUP (cweup.com) stands out as a preferred partner for businesses worldwide, offering a compelling combination of quality, innovation, and dedicated customer support. Our approach is built on a foundation of engineering excellence and a deep commitment to helping our clients succeed in their respective fields, whether it’s automotive, industrial control, medical devices, or consumer electronics.

Uncompromising Quality and Reliability

At WEUP, our reputation is built upon the bedrock of quality toggle switches and unwavering reliability. We firmly believe that the performance of your end product is intrinsically linked to the quality of its components, and we spare no effort in ensuring our toggle switches meet the most stringent standards.

Our commitment to excellence is evident in every stage of our process, from meticulous design and material selection to precision manufacturing and rigorous quality control. We employ a comprehensive suite of testing procedures, which can include electrical lifecycle testing to simulate years of operation, environmental testing to ensure performance under extreme temperatures and humidity, and mechanical endurance tests to verify the robustness of our switch mechanisms.

We utilize only high-quality materials, carefully chosen for their conductive properties, mechanical strength, and resistance to wear and environmental factors, ensuring enhanced durability and consistent performance. Furthermore, WEUP adheres to relevant international certifications and standards, such as ISO for quality management, UL for safety, and RoHS for hazardous substance restrictions (please verify and replace with WEUP’s actual certifications), providing you with the assurance that you are partnering with a truly reliable toggle switch supplier.

Expertise in Custom Toggle Switch Solutions

We recognize that standard, off-the-shelf components don’t always meet the unique or complex requirements of specialized applications. That’s why WEUP excels in providing custom toggle switch solutions, tailored precisely to your needs. Our experienced engineering team collaborates closely with you, taking the time to thoroughly understand your specific application challenges, operational environment, and performance targets. This collaborative toggle switch design process allows us to develop solutions that are not just functional but optimized for your system.

The scope of customization is extensive; we can modify actuators (style, length, material, color), terminals (type, orientation, plating), internal and external wiring configurations, sealing levels (from dust-proof to fully waterproof IP-rated solutions), housing materials, electrical ratings, and even custom markings or symbols for enhanced usability. The benefits of such tailored solutions are manifold, including improved performance, easier integration into your product, enhanced user experience, and often, a more cost-effective outcome by eliminating the need for workarounds or additional components. If you’re looking for a toggle switch that can transform your unique vision into a tangible, high-performing component, WEUP is your ideal partner.

Circuit Control Mechanism

- Making Contact: When the switch is moved to the “on” position, the internal contacts physically touch each other, creating a conductive path for electricity to flow through the circuit.

- Breaking Contact: When moved to the “off” position, the contacts physically separate, creating an air gap that prevents electricity from flowing through the circuit.

Maintained vs. Momentary Operation

- Maintained Operation: In this standard configuration, the switch remains in whatever position it is placed until manually moved again. When flipped to the “on” position, it stays on until deliberately switched off.

- Momentary Operation: These specialized toggle switches include a spring mechanism that automatically returns the lever to its default position when released. They function similarly to a doorbell button, remaining activated only while held in position.

Classification by Style

- Flip-up covers that must be lifted before accessing the toggle

- Boot covers that allow operation while providing environmental protection

- Safety covers that require deliberate action to access the switch

- Control panels with space constraints

- Applications where protruding toggles could be damaged

- Aesthetic installations where a sleek appearance is desired

- Dark environments where switch status must be visible

- Complex control panels where quick status identification is important

- Applications where confirmation of power flow is necessary

- Automotive and aviation dashboards

- Marine applications

- Outdoor equipment

- Food processing machinery

- High-humidity environments

- Applications exposed to cleaning sprays or splashes

- Industrial machinery

- Construction equipment

- Military applications

- High-vibration environments

- Applications requiring extended operational life

Related Product

Toggle Switches FAQs

Toggle Switches are commonly used in various applications, and people often have questions about them. Here are five of the most popular FAQs for Toggle Switches:

Toggle switches are typically made from durable materials like metal and high-quality plastic for the housing, with internal contacts made of conductive materials such as copper or silver. These materials ensure that the switches are robust, reliable, and capable of withstanding frequent use.

Yes, toggle switches can be used in both AC and DC circuits, provided they are rated for the appropriate voltage and current of the application. It is crucial to check the switch’s specifications to ensure it is suitable for the specific electrical requirements.

The advantages of using toggle switches include their simplicity, reliability, and ease of use. They are widely available in various configurations, making them versatile for different applications. Toggle switches are also durable and can handle high levels of current and voltage, depending on their design.

Yes, waterproof toggle switches are available and are especially useful in outdoor, marine, or industrial environments where the switch may be exposed to moisture, dust, or other harsh conditions. These switches are typically sealed with rubber or silicone to prevent water ingress and ensure long-term reliability.

Yes, many 12V toggle switches, including those from WEUP, are designed to withstand harsh environments. There are waterproof and dustproof models available that meet IP67 standards, making them suitable for use in marine, automotive, and industrial settings where exposure to water and dust is common.

Maintaining a toggle switch involves regularly inspecting it for signs of wear, ensuring it remains clean and free from dust and debris, and checking that the connections are secure. In environments exposed to moisture or dirt, it’s also important to ensure that any seals or gaskets remain intact to prevent damage.

A maintained toggle switch stays in the position it is toggled to until it is toggled back. For example, if you flip it to the “on” position, it stays on until you flip it to “off.” On the other hand, a momentary toggle switch only stays in the “on” position as long as you hold it down. Once you release it, it returns to the “off” position. This is ideal for functions that require a temporary connection, such as activating a horn or a starter motor.

Yes, in many cases, a toggle switch can be replaced with a rocker switch, provided the electrical ratings (voltage and current) and the type of operation (such as SPST or DPDT) are the same. However, you’ll need to ensure the replacement switch fits the existing mounting hole or panel cutout.

For high-current applications, it’s important to select a toggle switch that is rated for the specific current you need to control. Look for switches with a higher amperage rating, durable materials, and robust construction. Some high-current switches are also equipped with features like arc suppression to handle the increased electrical load.

The IP (Ingress Protection) rating indicates the level of protection a toggle switch has against dust and water. For example, an IP67 rating means the switch is completely dust-tight and can be submerged in water up to 1 meter deep for a specified time. This rating is particularly important for switches used in outdoor, marine, or industrial environments.