The main differences between illuminated and non-illuminated push buttons lie in their functionality, construction, and applications.

An illuminated push button is a type of electrical switch that includes a built-in light source — typically an LED or small lamp — which lights up the button or its lens.

Here’s a breakdown:

🔹 Definition

An illuminated push button is a mechanical switch with a built-in light indicator. When pressed, it completes (or breaks) an electrical circuit, while the illumination provides visual feedback about the button’s status or function.

🔹 Main Components

-

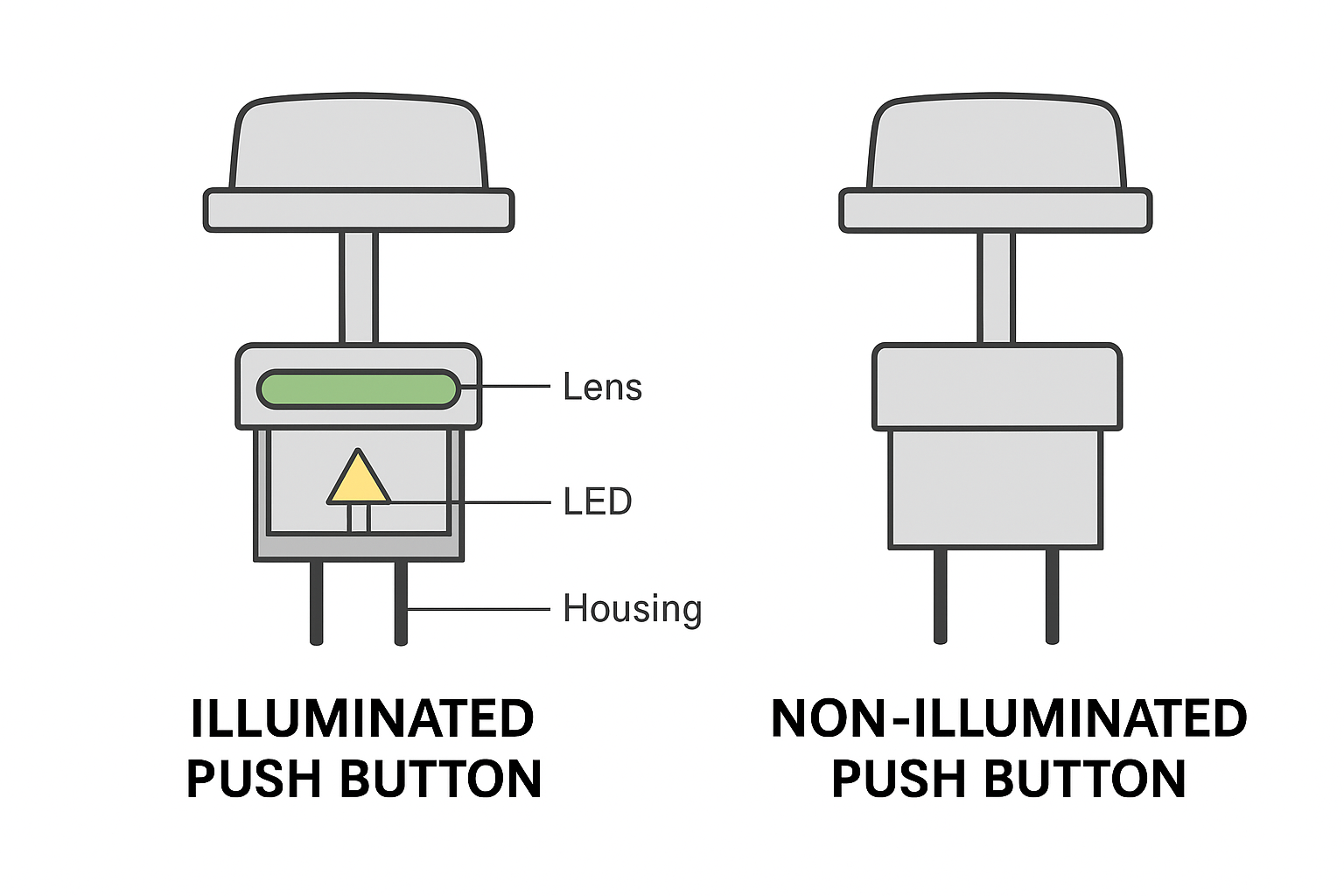

Actuator/Cap – The part you press (often transparent or translucent).

-

Lamp or LED – Provides illumination.

-

Lens – Distributes or colors the light.

-

Switch Contacts – Open or close the circuit when pressed.

-

Housing/Body – Encloses and protects internal parts.

Differences Between illuminated and non-illuminated Push Buttons

The main differences between illuminated and non-illuminated push buttons lie in their functionality, construction, and applications. Here’s a clear comparison:

| Aspect | Illuminated Push Button | Non-Illuminated Push Button |

| Lighting Feature | Has an internal light source (usually LED or incandescent lamp) that lights up when activated or as an indicator. | No built-in lighting; relies on external indicators or labels. |

| Purpose of Illumination | Provides visual feedback — can indicate power status, operation mode, fault condition, or simply make the button visible in low-light areas. | Purely mechanical actuation; no visual status indication. |

| Construction | Includes extra components such as a lamp/LED, lens, and sometimes a separate circuit for illumination. | Simpler design — only the switch mechanism without any light source. |

| Wiring | Requires additional wiring for the lamp circuit (power supply and sometimes control circuit). | Only has switch terminals; simpler wiring. |

| Cost | More expensive due to added light source and complexity. | Cheaper and easier to install. |

| Maintenance | Lamp or LED may need replacement over time (especially older incandescent types). | Minimal maintenance; fewer components. |

| Typical Applications | Control panels, machinery, industrial systems, automotive dashboards — where visual indication is needed. | Basic control applications, simple devices, or where indication is not necessary. |