In the intricate world of electrical circuits and system design, switches act as the gatekeepers of current flow, directing power and signals precisely where they need to go. Among the diverse array of switch types available, the Single Pole Double Throw (SPDT) switch stands out as a remarkably versatile and fundamental component.

Its ability to route a single input to one of two possible outputs makes it indispensable in countless applications, from simple household gadgets to complex industrial machinery and sophisticated automotive systems. For procurement professionals, engineers, and designers, understanding the nuances of the SPDT switch is crucial for making informed purchasing decisions and ensuring optimal system performance. This comprehensive guide is designed specifically for potential buyers, offering a deep dive into what an SPDT switch is, how it works, its key benefits, common applications, and critical factors to consider when sourcing these essential components. Our goal is to equip you with the knowledge needed to confidently select and procure the right SPDT switches for your specific requirements, ensuring reliability and efficiency in your projects.

Decoding the Terminology: Understanding Poles, Throws, and SPDT

Navigating the specifications of electrical components often involves deciphering specific terminology. When it comes to switches, understanding the concepts of “pole” and “throw” is fundamental to grasping their function and selecting the appropriate type. Let’s break down these terms to clearly define what makes an SPDT switch unique.

What Does “Pole” Mean in an Electrical Switch?

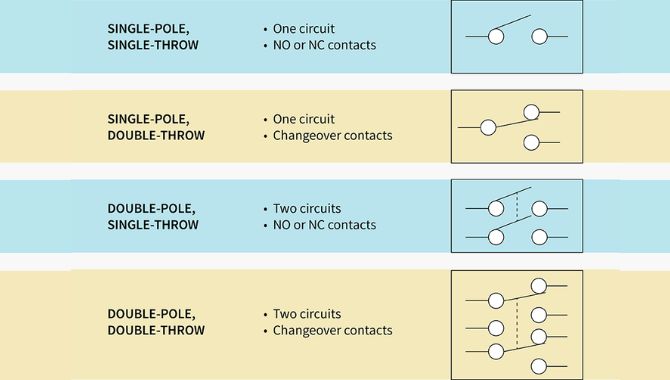

The term “pole” refers to the number of separate electrical circuits that a single switch can control or complete simultaneously. Think of each pole as an independent input pathway within the switch. A single pole switch, therefore, is designed to control just one electrical circuit. It acts like a single gate, managing the flow within one specific path. This is the most common configuration found in simple on/off switches, where the primary function is merely to make or break a single connection within a circuit.

What Does “Throw” Mean in an Electrical Switch?

While the “pole” defines how many circuits are controlled, the “throw” indicates the number of distinct output connections or positions that each pole can be connected to. It essentially describes the number of paths the input current from the pole can be directed towards. A “single throw” switch connects the pole to only one output terminal, creating a simple make-or-break (ON/OFF) scenario. Conversely, a double throw switch provides each pole with a choice between two different output terminals. This allows the input circuit controlled by the pole to be directed to one of two possible destinations.

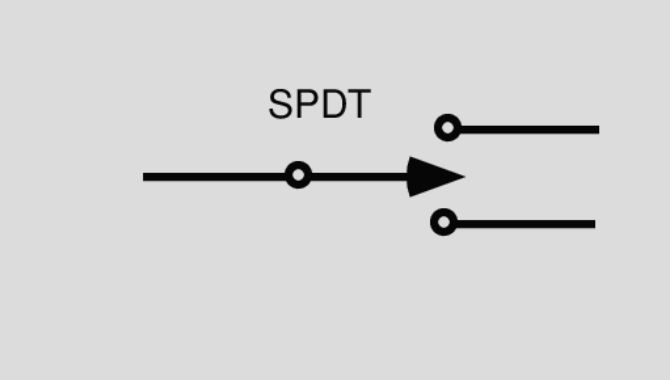

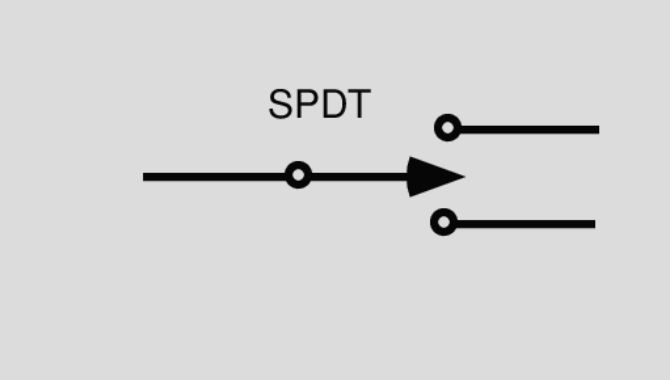

Defining the SPDT Switch: One Input, Two Output Choices

Bringing these concepts together, a Single Pole Double Throw (SPDT) switch is precisely what its name implies: it has one pole (controlling a single input circuit) and double throw capability (allowing that input circuit to be connected to one of two different output terminals). Imagine arriving at a fork in the road; you have one path leading you to the fork (the single pole), and you must choose one of two directions to continue your journey (the double throw). An SPDT switch performs this function for electrical current, providing a mechanism to select between two alternative paths for a single input signal or power source. It never connects the input to both outputs simultaneously, ensuring a clear selection between the two options.

How an SPDT Switch Works: The Core Mechanism

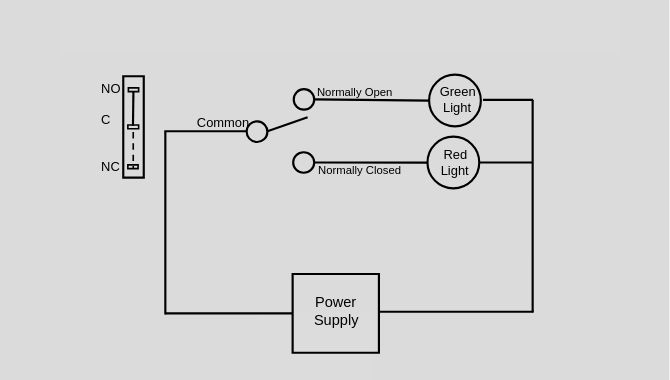

The magic of the SPDT switch lies in its internal construction, which typically involves three main terminals. The input circuit connects to the Common (C) terminal. This is the pivot point, the start of the fork in the road. The two possible output paths connect to the other two terminals. One is designated as Normally Open (NO), meaning it is disconnected from the Common terminal when the switch is in its resting or default state. The other is the Normally Closed (NC) terminal, which is connected to the Common terminal in the resting state.

An actuator (like a toggle, button, or lever) is used to physically move an internal contact. When the switch is actuated, this internal contact pivots. It breaks the connection between the Common (C) and the Normally Closed (NC) terminal and simultaneously establishes a new connection between the Common (C) and the Normally Open (NO) terminal. This characteristic action is often described as break-before-make, meaning the existing connection is broken before the new one is made. This prevents momentary short circuits between the two output paths during the switching transition, a critical feature for many sensitive applications. Releasing the actuator (in momentary switches) or moving it to its alternate position (in latching switches) reverses the connection state, connecting C to NC and disconnecting C from NO, or maintaining the C-to-NO connection depending on the switch type.

Anatomy of an SPDT Switch: Key Components You Should Know

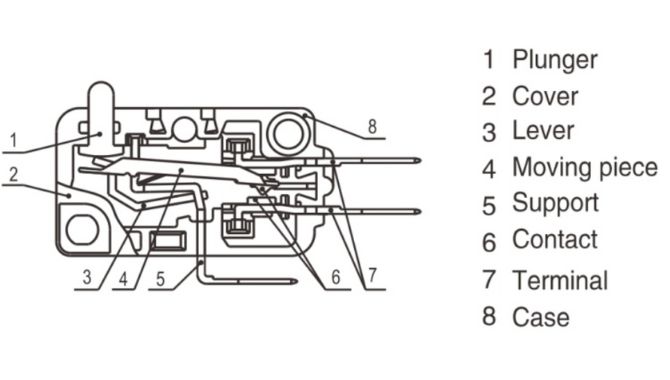

To fully appreciate the functionality and select the appropriate SPDT switch for your needs, it’s helpful to understand its core components. While designs can vary, most SPDT switches share a common internal structure responsible for their reliable operation.

The Terminals: Connection Points (Common, NO, NC)

As previously mentioned, the terminals are the critical connection points where the switch interfaces with the external circuit. In a standard SPDT switch, you will find three essential terminals:

- Common (C): This is the input terminal. It’s the central point where the signal or power source for the single pole connects to the switch. The current flows into the switch via the Common terminal.

- Normally Open (NO): This is one of the two output terminals. In the switch’s default or unactuated state, this terminal is disconnected from the Common terminal. When the switch is activated, the internal mechanism connects the Common terminal to the NO terminal, completing this circuit path.

- Normally Closed (NC): This is the second output terminal. In the switch’s default or unactuated state, this terminal is connected to the Common terminal, allowing current to flow through this path. When the switch is activated, the connection between the Common and NC terminals is broken.

Understanding the roles of these three terminals (C, NO, NC) is fundamental to correctly wiring and utilizing an SPDT switch in any circuit design.

The Actuator: Triggering the Switch

The actuator is the part of the switch that a user (or a mechanical force) interacts with to change the switch’s state – to move the internal contact between the NO and NC positions. The type of actuator significantly influences how the switch is used and integrated into a device. Common actuator types for SPDT switches include:

- Toggle Switches: Feature a lever that is moved back and forth.

- Rocker Switches: Pivot on a central point when pressed on one side.

- Slide Switches: Have a sliding knob or button that moves linearly.

- Pushbutton Switches: Activated by pressing a button (can be momentary or latching).

- Rotary Switches: Use a rotating knob to select different positions (though less common for simple SPDT, often used for multi-pole/multi-throw variants).

- Microswitches (Snap-Action Switches): Often actuated by a small amount of physical force via a lever or plunger, providing rapid switching action.

The choice of actuator depends heavily on the application’s user interface requirements, mounting style, and the required operational feel. Considering the actuator type is crucial when sourcing SPDT switches.

Internal Contacts & Housing Materials

While less visible, the internal components play a vital role in the switch’s performance and longevity. The internal contacts, which physically make and break the electrical connection, are typically made from conductive metals like copper alloys, often plated with materials like silver or gold to improve conductivity and resist corrosion and wear. The quality of these contacts directly impacts the switch’s current-carrying capacity, electrical resistance, and operational lifespan.

The housing encloses the internal mechanism, providing structural support and protection from the environment. Housing materials range from standard plastics (like nylon or PBT) for general use to more robust materials or sealed designs for harsh environments requiring resistance to dust, moisture (IP ratings), or higher temperatures. For buyers, considering the contact and housing materials is essential when sourcing SPDT switches for demanding applications where reliability and durability are paramount.

Why Choose an SPDT Switch? Key Benefits for Your Application

The enduring popularity of the SPDT switch stems from a combination of functional advantages that make it a highly effective solution for various circuit control challenges. Understanding these benefits can help buyers justify its selection over other switch types.

Unmatched Versatility: Controlling Two Circuits from One Source

The primary benefit of an SPDT switch is its inherent ability to direct a single input signal or power source to one of two distinct outputs. This fundamental capability allows for simple yet powerful control logic, enabling functions like selecting between two modes of operation, routing audio signals, switching between power sources (though often requiring specific types like center-off), or activating one of two different indicator lights based on a condition. This versatility makes it a go-to component for designers needing basic routing or selection functionality.

Operational Flexibility: ON/ON and ON/OFF/ON Configurations

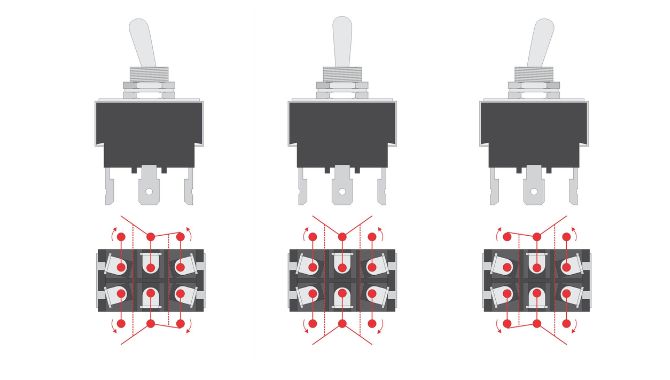

SPDT switches typically come in two main operational configurations:

- ON/ON: In this type, the common terminal is always connected to one of the two output terminals (either NO or NC, depending on the actuator position). There is no ‘off’ position where the common is disconnected from both outputs. This is ideal for selecting between two active states or modes.

- ON/OFF/ON: Some SPDT switches feature a third, central actuator position where the common terminal is disconnected from both the NO and NC terminals. This provides a true ‘off’ state in addition to the two ‘on’ states, offering further control flexibility, particularly useful for applications requiring a neutral or disconnected state.

This operational flexibility allows buyers to choose the exact switching behavior needed for their application. Need help determining the right configuration? Contact our experts!

Efficient Signal Routing and Selection

Whether it’s selecting between two sensor inputs, choosing an audio source, or directing a control signal, the SPDT switch provides an efficient and straightforward method for signal routing. Its simple mechanism minimizes complexity and potential points of failure compared to more elaborate electronic switching solutions, especially for basic selection tasks.

Reliability and Durability When Sourced Correctly

s use robust materials for contacts and housings, ensuring consistent performance even under demanding conditions. As a buyer, focusing on ensures you leverage this potential for Electromechanical switches like the SPDT, particularly those designed for industrial or commercial use, can offer excellent reliability and long operational lifespans, often rated for tens of thousands or even millions of actuation cycles. However, this is heavily dependent on sourcing quality components. Reputable s use robust materials for contacts and housings, ensuring consistent performance even under demanding conditions. As a buyer, focusing on SPDT switches from trusted ensures you leverage this potential for durability.

Cost-Effectiveness for Specific Control Needs

For applications requiring the simple redirection of a single circuit to one of two outputs, the SPDT switch often represents the most cost-effective solution. Compared to using multiple SPST switches with complex logic, or employing more advanced electronic switches or relays, a single SPDT switch can achieve the desired functionality with fewer components, reduced wiring complexity, and lower overall cost, especially in high-volume production.

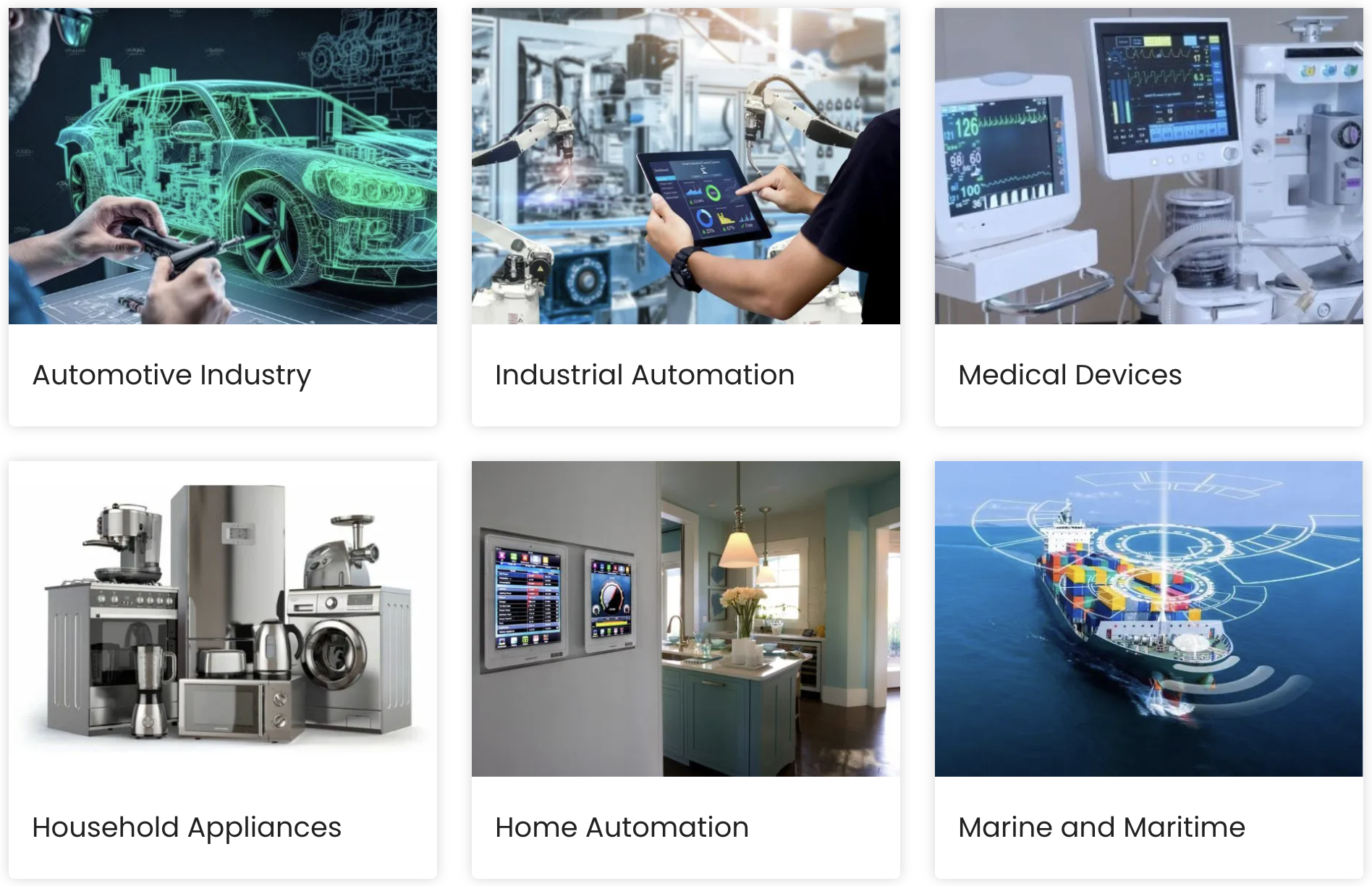

Real-World Applications: Where are SPDT Switches Making a Difference?

The theoretical benefits of the SPDT switch translate into practical advantages across a vast spectrum of industries and products. Its ability to provide a simple choice between two circuit paths makes it a fundamental building block in countless designs. If your application falls into one of the categories below, an SPDT switch might be the ideal solution. Here are just a few examples of where potential buyers might encounter or specify SPDT switches:

- Industrial Control Panels and Machinery: Used for mode selection (e.g., Manual/Auto), activating different process steps, or controlling indicator lights based on machine status. Their robustness makes them suitable for demanding factory environments.

- Automotive Systems: Found in power seat controls (directing motor polarity for forward/backward movement), turn signal indicators (though often integrated into more complex modules now), headlight selectors (high/low beam in simpler designs), and mode selection buttons on dashboards.

- Telecommunications Infrastructure: Utilized in older routing equipment or test setups for switching signal paths, though often replaced by solid-state solutions in modern high-speed networks.

- Consumer Electronics and Appliances: Commonly used as selector switches – think input selection on older stereos (Phono/Aux), function selection on kitchen appliances, or power mode switches.

- Audio Equipment: Guitar pickup selectors are a classic example, allowing musicians to choose between neck, bridge, or combined pickups. Also used in amplifiers or mixers for routing audio signals.

- Test and Measurement Devices: Employed in multimeters or oscilloscopes for selecting measurement ranges or input channels, providing a reliable way to alter the instrument’s internal circuitry.

- Reversing DC Motor Polarity: A very common application. By wiring the motor connections across the NO and NC terminals and feeding power to the common, an SPDT switch can easily reverse the direction of a DC motor, essential for actuators, robotics, and simple motion control.

- Safety Interlock Systems: Can be used in safety circuits where opening a guard or panel needs to switch a machine from a running state (connected via NC) to a safe or stopped state (connected via NO, perhaps activating an alarm or brake).

This list is far from exhaustive, but it highlights the sheer versatility of the SPDT switch. Its fundamental operating principle finds utility wherever a single source needs to be directed towards one of two possible outcomes. Unsure if an SPDT fits your specific application? Our technical team can help assess your needs.

SPDT vs. The Alternatives: Making the Right Switch Selection

While the SPDT switch is incredibly useful, it’s not the only option available. Understanding how it compares to its closest relatives – the SPST and DPDT switches – is crucial for buyers to ensure they are selecting the most appropriate and cost-effective component for their specific circuit requirements.

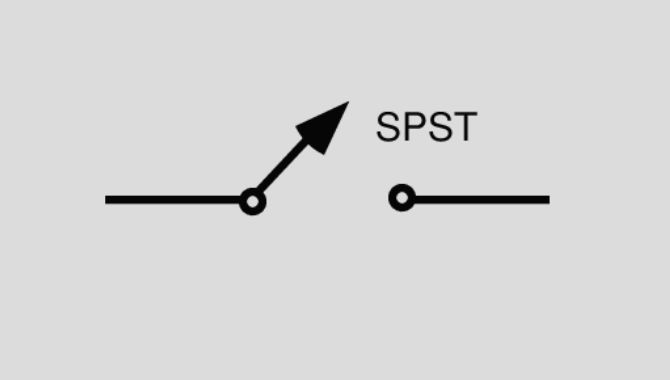

SPDT vs. SPST (Single Pole Single Throw): When You Need Options

The Single Pole Single Throw (SPST) switch is the simplest type, acting as a basic ON/OFF switch for a single circuit. It has only two terminals – one input (pole) and one output. It either completes the circuit (ON) or breaks it (OFF).

The key difference is choice: SPST offers no choice, only connection or disconnection. SPDT offers a choice between two different output paths (connecting the single pole to either the NO or the NC terminal).

Choose SPST when: You simply need to turn a single circuit ON or OFF. Choose SPDT when: You need to route a single circuit to one of two different destinations or select between two states.

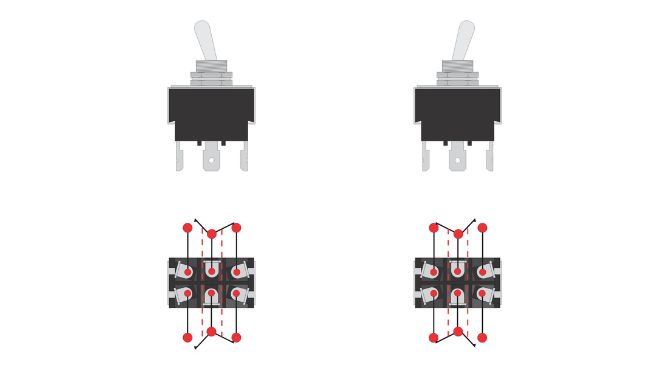

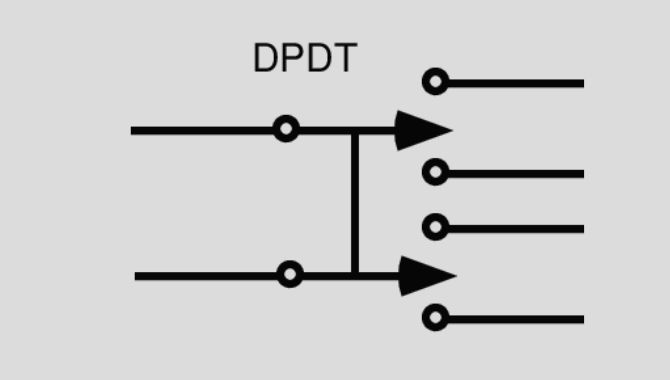

SPDT vs. DPDT (Double Pole Double Throw): Complexity vs. Necessity

The Double Pole Double Throw (DPDT) switch is essentially two SPDT switches mechanically linked and operated by a single actuator. It has six terminals: two independent Common (input) terminals, and each Common can connect to one of its two associated output terminals (two NOs and two NCs in total). A DPDT switch simultaneously controls two separate and isolated circuits, switching each circuit between two possible outputs.

The key difference is the number of circuits controlled: SPDT controls one circuit with two output options. DPDT controls two independent circuits simultaneously, each with two output options.

Choose SPDT when: You only need to control a single circuit and route it to one of two outputs. Choose DPDT when: You need to simultaneously switch two separate circuits (e.g., switching both the positive and negative lines of a power supply, or controlling two different signals with one action).

Identifying When SPDT is the Optimal Solution for Buyers

From a procurement perspective, the SPDT switch is the optimal choice when the application specifically requires a single input signal or power source to be directed to one, and only one, of two possible output paths at any given time. If the requirement is simpler (just ON/OFF), an SPST is likely more cost-effective. If the requirement is more complex (controlling two circuits simultaneously), a DPDT is necessary. Selecting the SPDT when its specific functionality matches the need ensures the most efficient design in terms of component count, wiring complexity, and often, cost. Need help comparing switch types for your project? Explore our resources or contact us!

Critical Factors When Sourcing SPDT Switches: A Buyer’s Checklist

Selecting the right SPDT switch goes beyond understanding its basic function. For procurement professionals and engineers, ensuring the chosen component meets all technical, environmental, and regulatory requirements is paramount. Here’s a checklist of critical factors to consider during the sourcing process:

Electrical Ratings: Matching Voltage and Current Needs

This is arguably the most critical specification. The SPDT switch must be rated to handle the maximum voltage (often specified in VDC and/or VAC) and current (Amperage) it will encounter in the circuit. Exceeding these electrical ratings can lead to switch failure, overheating, arcing, or even fire hazards. Always consult the datasheet and ensure the switch’s ratings provide a safe margin above the application’s operating parameters. Need help interpreting datasheets? Our team can assist.

Actuation Type: Momentary vs. Latching Action

The required actuation type depends entirely on how the switch needs to behave in the application:

- Momentary: The switch only maintains its actuated state (connecting C to NO) while the actuator is actively pressed or held. Upon release, it springs back to its default state (connecting C to NC). Ideal for functions like jog controls, reset buttons, or signaling.

- Latching: The switch stays in the position it was last moved to, even after the actuator is released. It requires a separate action to return it to the previous state. Suitable for ON/OFF functions, mode selection, or maintaining a specific circuit path.

Choosing the wrong actuation type will result in incorrect circuit behavior.

Physical Footprint and Mounting Style (PCB, Panel Mount)

Space is often a constraint in modern electronic designs. The physical dimensions (footprint) of the SPDT switch must fit within the available area. Equally important is the mounting style:

- PCB Mount: Designed to be soldered directly onto a Printed Circuit Board (through-hole or surface mount – SMT/SMD).

- Panel Mount: Designed to be installed through a cutout in an enclosure or panel, often secured with a nut or clips.

The mounting style dictates how the switch integrates mechanically into the final product. We offer various mounting options to fit your design.

Environmental Considerations (Temperature Range, Sealing/IP Rating)

Will the SPDT switch operate in extreme temperatures, be exposed to dust, moisture, or chemicals? The operating temperature range specified in the datasheet must encompass the application’s environmental conditions. For protection against solids and liquids, look for an IP (Ingress Protection) rating (e.g., IP65, IP67). Sealed switches are essential for harsh environments to ensure reliability and prevent premature failure. Browse our selection of environmentally sealed SPDT switches.

Required Certifications and Compliance (UL, RoHS, etc.)

Depending on the end market and application, specific certifications and compliance standards may be mandatory. Common requirements include:

- UL (Underwriters Laboratories) / cUL: Safety certification, particularly important for North American markets.

- CE: Conformity marking for products sold within the European Economic Area.

- RoHS (Restriction of Hazardous Substances): Restricts the use of specific hazardous materials.

Ensure the sourced SPDT switches meet all necessary regulatory and compliance standards for your target market. Our switches meet rigorous international standards.

How to Read an SPDT Switch Datasheet Effectively

The datasheet is the definitive source of truth for any component. When reviewing an SPDT switch datasheet, pay close attention to:

- Electrical Ratings (Voltage, Current – resistive vs. inductive loads)

- Contact Resistance

- Insulation Resistance

- Dielectric Strength

- Operating and Storage Temperature Ranges

- Mechanical Life (number of actuation cycles)

- Electrical Life (cycles under load)

- Actuation Force

- Terminal Type and Dimensions

- Mounting Details and Recommended Panel Cutout (if applicable)

- Materials Used (contacts, housing)

- Certifications and Compliance Information

Understanding how to navigate and interpret the datasheet is a critical skill for buyers.

Partnering for Success: Finding Your Ideal SPDT Switch Supplier

. Building a relationship with the right Sourcing components like SPDT switches, especially in volume, involves more than just finding the lowest . Building a relationship with the right SPDT switch supplier can significantly impact project success, product quality, and supply chain resilience.

Why Quality and Consistency Matter in Bulk Purchases

When procuring hundreds or thousands of switches, quality and consistency are non-negotiable. A reliable supplier implements stringent quality control processes to ensure that every SPDT switch meets the specified parameters. Inconsistent performance or high failure rates can lead to costly rework, field failures, and damage to your brand reputation. Partnering with a supplier known for quality minimizes these risks.

The Value of Technical Support and Customization Options

An ideal SPDT switch supplier acts as a partner, not just a vendor. Look for who offer accessible technical support to help answer questions about specifications, applications, or potential issues. Furthermore, some applications may require slight modifications or customization (e.g., specific wire lengths, custom actuators, unique markings). A supplier willing and able to provide customization options can be invaluable.

Ready to Source High-Quality SPDT Switches?

Navigating the world of SPDT switches requires careful consideration of technical specifications, application demands, and supplier reliability. Ensuring you select the right component is crucial for the performance and longevity of your end product.

We offer a wide range of reliable, high-performance SPDT switches designed to meet diverse industrial, commercial, and consumer application needs. Our commitment to quality, consistency, and customer support ensures you receive components you can trust. Explore our comprehensive catalog or contact our experienced technical team today for personalized guidance and to discuss your specific requirements. Let us help you find the perfect SPDT switch solution.

| Voltage | Application |

| 12V | Automotive Electrical Systems UPS (Uninterruptible Power Supply) Solar Power Systems LED Lighting Portable Electronics |

| 24V | Automotive and Truck Applications Power Tools and Equipment Small Electric Vehicles Industrial Automation Equipment |

| 36V | Electric Bicycles and Scooters Power Tools Small Electric Vehicles |

| 48V | Electric Bicycles and Scooters Electric Vehicles (Light) Energy Storage Systems Power Tools |

| 110V-120V | Residential Power Systems Electronics Power Tools |

| 220V-240V | C

ommercial Power Supply |

What are the conventional currents?

| Electric current | Application |

| 0.1A-1A | Tiny electrical flows, often used in low-power devices. |

| 6A | Mid-range currents suitable for more demanding consumer and automotive applications. |

| 10A-16A | Electric bicycles, scooters, higher-powered tools, residential appliances. |

| 20A | Energy storage systems, light EVs, larger power tools. |

| 30A | Small residential power systems, heavy-duty tools, and electronics. |

| 40A | Industrial equipment, HVAC systems, commercial appliances. |

Summary of Applications:

| Configuration | Applications |

|---|---|

| ON OFF | Ligh |

| ON ON | Circuit selecti |

| ON OFF ON | Fan spee |

| (ON) OFF ON | Vehicle |

| (ON) OFF (ON) | Motor direc |

Features

After selecting the voltage, you can choose the specific switch type for your application.