In the complex world of electrical components, switches play a fundamental role in controlling the flow of power. Among the diverse array of switch types, Double Pole Single Throw (DPST) switches stand out as essential components, particularly vital in high-power or safety-critical applications where managing multiple circuits simultaneously is paramount. These devices are more than simple on/off mechanisms; they are crucial gatekeepers ensuring the safe, reliable, and efficient operation of demanding electrical systems, from heavy industrial machinery to common household appliances operating on higher voltages. Understanding the function and application of DPST switches is therefore critical for engineers, technicians, and procurement specialists tasked with specifying or purchasing the right components for their needs.

This guide aims to provide a clear, comprehensive understanding of DPST switches, demystifying their operation, highlighting their advantages, and guiding buyers towards making informed decisions. The core strength of a DPST switch lies in its ability to control two separate electrical circuits concurrently with a single action, offering a significant advantage in terms of enhanced safety and operational efficiency, especially when complete isolation is required.

Understanding Switch Basics: Poles, Throws, and the DPST Definition

Before delving deeper into the specifics of the DPST switch, it’s crucial to grasp the fundamental terminology used to classify switches: “poles” and “throws.” These terms define the internal configuration and functional capability of any switch, dictating how many circuits it can control and how it directs the electrical current within those circuits.

What Does “Pole” Mean in an Electrical Switch?

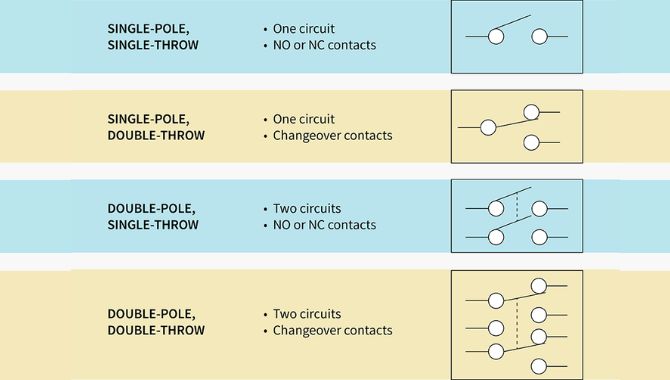

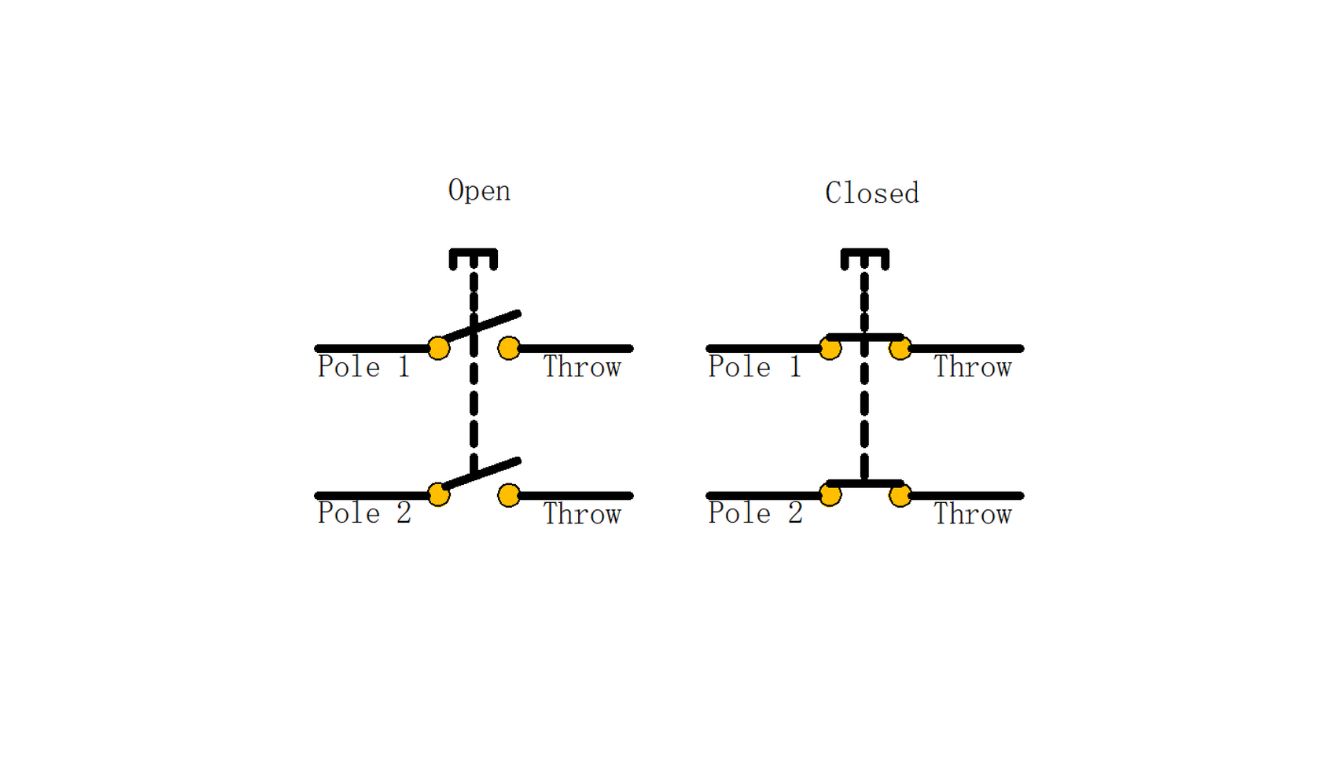

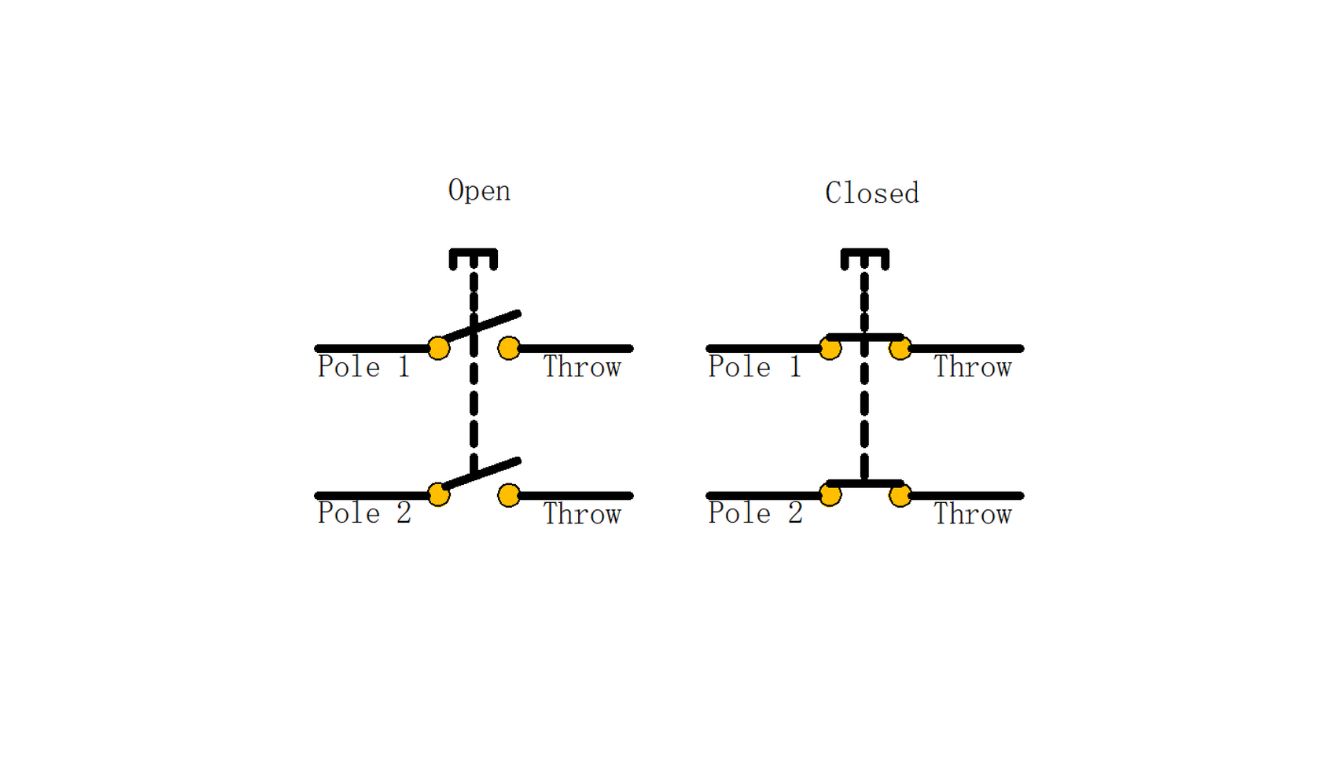

The term “pole” refers to the number of separate electrical circuits that a single switch can control or complete. Think of each pole as an independent pathway that the switch manages. A Single Pole (SP) switch, the most common type found in simple light switches, controls just one circuit. It makes or breaks the connection along a single electrical path. In contrast, a Double Pole (DP) switch, as the name implies, is designed to simultaneously control two independent circuits. It essentially acts like two separate single pole switches that are mechanically linked and operated by the same actuator (like a toggle or button). This capability is crucial in applications where two conductors need to be switched together, such as in 240-volt systems or for isolating both the live and neutral lines for safety.

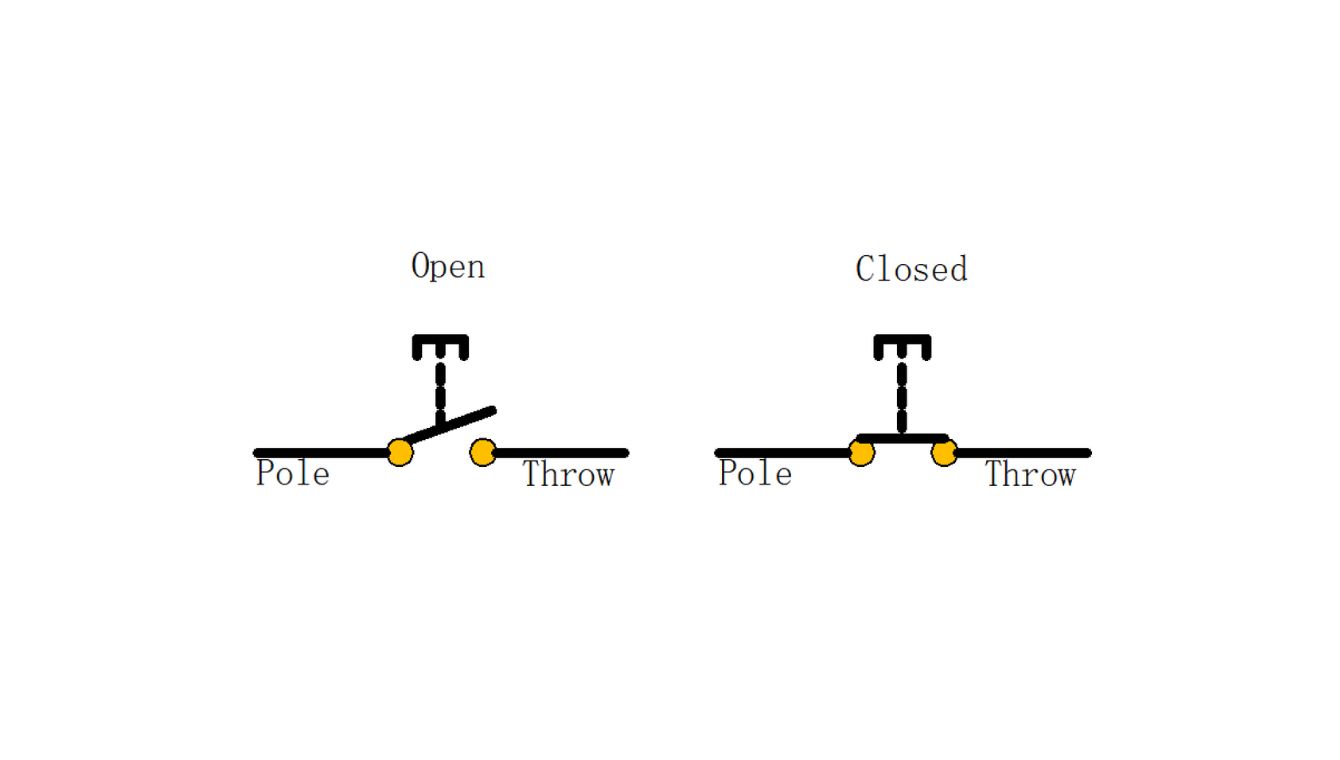

What Does “Throw” Mean in an Electrical Switch?

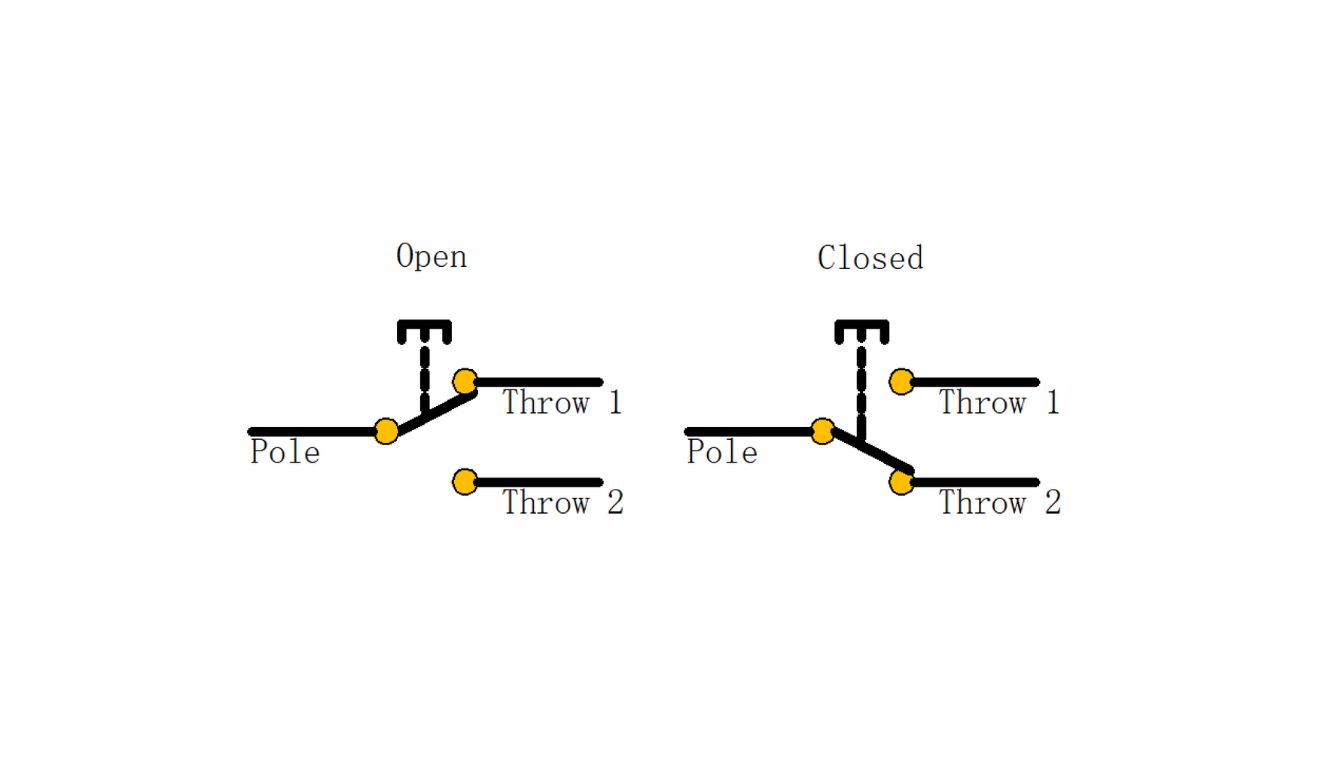

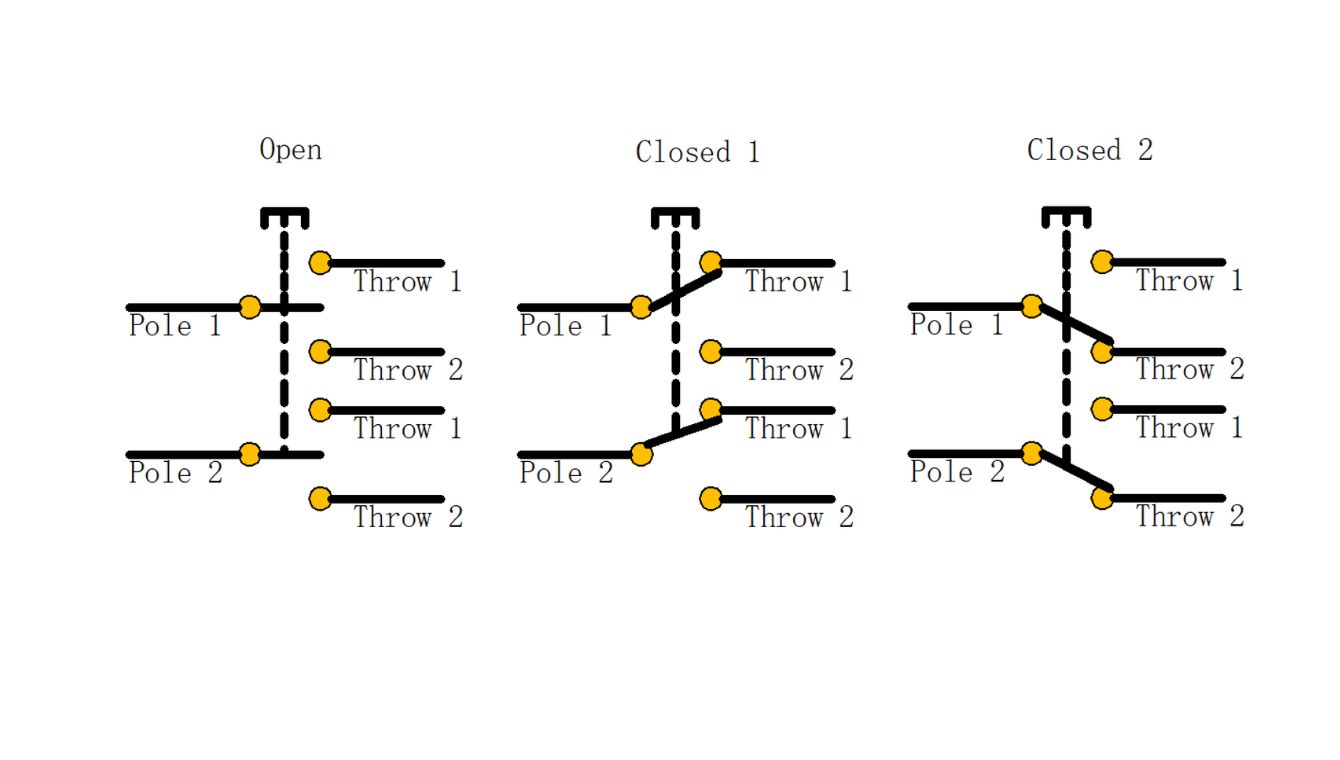

While “pole” defines how many circuits are controlled, “throw” indicates the number of distinct ON positions or output connections each pole can connect its input to. A Single Throw (ST) switch offers a simple ON/OFF functionality. In the ON position, it connects the input terminal to a single output terminal, completing the circuit. In the OFF position, the connection is broken. There is only one path for the current to take when the switch is engaged. Conversely, a Double Throw (DT) switch provides two ON positions for each pole. It allows the input terminal of a pole to be connected to one of two different output terminals. This enables the switch to alternate the connection between two different circuits or paths, often including a center OFF position in some configurations.

Defining the DPST Switch: Bringing Poles and Throws Together

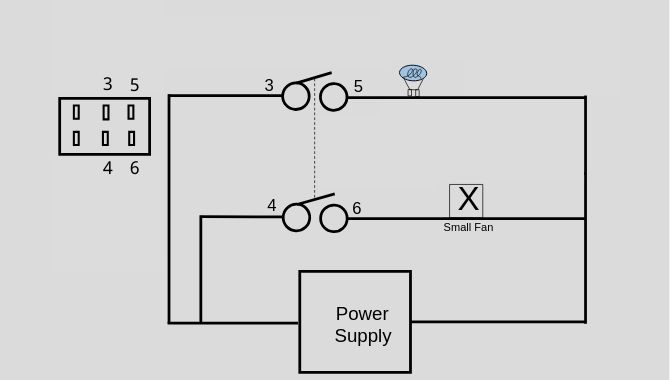

Now, combining these concepts gives us the precise definition of a Double Pole Single Throw (DPST) switch. It features Double Pole construction, meaning it controls two separate and electrically isolated circuits simultaneously. It also has a Single Throw configuration, meaning each of these two poles has only one ON position, providing a straightforward ON/OFF control for both circuits concurrently. When a DPST switch is activated (turned ON), it completes both circuits. When it is deactivated (turned OFF), it simultaneously breaks or opens both circuits. This simultaneous action is key to its functionality. Structurally, a DPST switch typically features four terminals: two input terminals (often labeled L1 and L2 for Line 1 and Line 2) and two corresponding output terminals (often labeled T1 and T2 for Load 1 and Load 2). This four-terminal setup allows it to effectively make or break connections in two parallel paths with a single user action.

How Does a Double Pole Single Throw Switch Work? Mechanics Explained

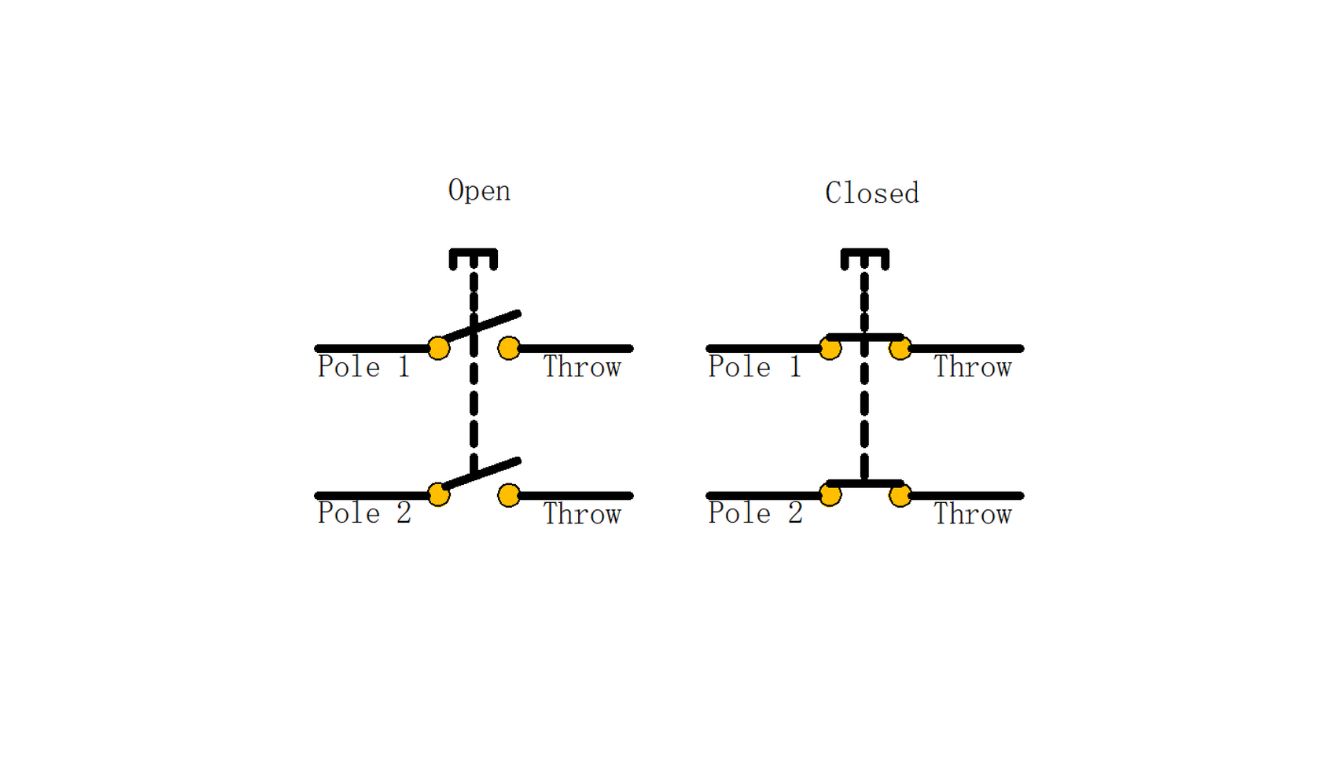

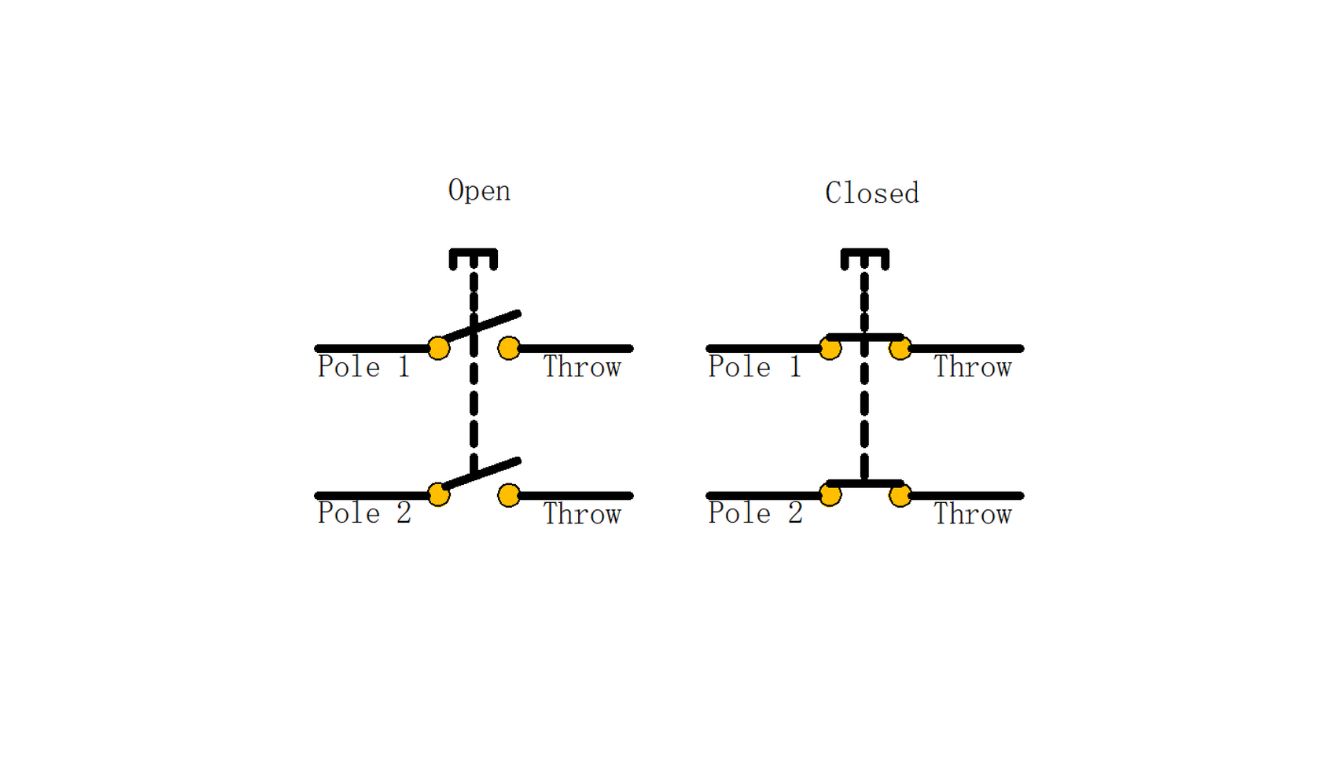

The defining characteristic of a DPST switch lies in its internal mechanics, which enable the simultaneous control of two independent circuits. Internally, the switch houses two separate sets of electrical contacts, essentially mirroring two SPST switches side-by-side. The crucial element is the mechanical interlock – a physical linkage connecting the movable parts (contact arms) of both sets of contacts. This interlock ensures that when the external actuator (which could be a toggle lever, a rocker button, a push-button, or a rotary knob) is operated, both sets of contacts move in perfect unison.

When the DPST switch is moved to the ON position, the actuator pushes both sets of movable contacts against their corresponding fixed contacts. This action closes both circuits simultaneously, allowing electrical current to flow through each independent path from its input terminal (e.g., L1, L2) to its respective output terminal (e.g., T1, T2). Conversely, when the switch is moved to the OFF position, the actuator pulls both sets of movable contacts away from their fixed counterparts, simultaneously breaking or opening both circuits. This immediate and concurrent interruption of current flow in both paths is fundamental to the safety and control functions provided by DPST switches, especially in applications requiring complete isolation.

The standard schematic symbol for a DPST switch visually represents this concept. It typically shows two parallel single-throw switches with a dotted line connecting their actuators, clearly indicating the mechanical interlock and simultaneous operation. Understanding this basic mechanism is key to appreciating why DPST switches are specified for applications demanding robust, synchronized control over dual electrical paths.

DPST vs. Other Common Switch Types: Choosing the Right Solution

Selecting the appropriate switch is crucial for system performance, safety, and cost-effectiveness. While the DPST switch offers unique advantages, understanding how it compares to other common switch types – SPST, SPDT, and DPDT – helps buyers pinpoint the exact solution for their specific requirements.

DPST vs. SPST (Single Pole Single Throw): When One Circuit Isn’t Enough

The most basic comparison is between DPST and SPST (Single Pole Single Throw) switches. An SPST switch is the simplest form, controlling just one circuit with a single ON/OFF action (two terminals). It’s like a standard light switch. The key difference is capacity: a DPST switch controls two independent circuits simultaneously using its four terminals. Choose DPST over SPST when you need to make or break connections in two separate paths concurrently, such as switching both live conductors in a 240V system or controlling two different functions with one action.

DPST vs. SPDT (Single Pole Double Throw): One Circuit, Two Paths

An SPDT (Single Pole Double Throw) switch controls a single circuit (one pole) but directs the current to one of two possible output paths (double throw). It typically has three terminals: one common input and two outputs. It’s used for changeover applications, like switching control between two different devices or selecting one of two power sources. This differs significantly from a DPST switch, which controls two separate circuits but only provides a single ON/OFF path for each (single throw). If you need to switch two circuits ON or OFF together, DPST is the choice. If you need to reroute a single circuit between two options, SPDT is required.

DPST vs. DPDT (Double Pole Double Throw): Two Circuits, Two Paths

A DPDT (Double Pole Double Throw) switch is like two SPDT switches combined, operated by a single actuator. It controls two separate circuits (double pole), and for each circuit, it can direct the current to one of two possible output paths (double throw). It typically has six terminals. DPDT switches are used for more complex tasks like reversing motor polarity or simultaneously switching two different signals between two different options. The primary difference from a DPST switch is the throw: DPST offers simple ON/OFF control for its two circuits (single throw), while DPDT provides changeover capability for its two circuits (double throw). Use DPST for simultaneous ON/OFF; use DPDT for simultaneous changeover.

Key Applications: Where are DPST Switches Indispensable?

The versatility and safety features of Double Pole Single Throw (DPST) switches make them indispensable in a wide range of applications, particularly where controlling higher voltages, managing significant electrical loads, or ensuring complete circuit isolation is critical. Understanding why DPST is the preferred choice in these scenarios helps buyers appreciate their value and specify them correctly.

High-Power Appliances & Equipment (240V Circuits)

Many heavy-duty appliances and pieces of equipment operate on 240V power, which typically uses two live conductors (two “hot” wires). Examples include large central air conditioners (AC) units, electric water heaters, commercial ovens, electric ranges/stoves, large pumps, and powerful motors found in workshops or industrial settings. For these applications, safety regulations and electrical codes often mandate the simultaneous disconnection of both live conductors when the device is switched off or needs to be isolated. An SPST switch would only break one conductor, leaving the appliance potentially live and hazardous. A DPST switch is the ideal solution here, as its double pole design ensures that both current-carrying conductors are completely and simultaneously disconnected from the power source with a single action, providing a crucial layer of safety for users and maintenance personnel.

Industrial Machinery Control Panels

In industrial environments, DPST switches are frequently used in control panels for machinery. They can serve as main power switches for smaller machines or specific subsystems, providing a clear ON/OFF control point. For instance, a DPST switch might control both the main motor power and a related control circuit simultaneously. Their ability to handle higher currents and voltages common in industrial settings, combined with their robust construction, makes them reliable choices for demanding operational conditions. They offer a simple yet effective way to completely energize or de-energize two separate parts of a machine or system via one control point.

Safety Disconnect & Isolation Switches

One of the most critical roles for DPST switches is serving as safety switches or isolation switches. During maintenance, repair, or emergency situations, it is absolutely essential to completely de-energize equipment to prevent electrical shock or accidental startup. A DPST switch, often housed in a lockable enclosure for lockout/tagout (LOTO) procedures, provides a reliable means to achieve this isolation. By breaking both poles of the supply circuit (e.g., both live lines in a 240V system, or live and neutral in some specific control scenarios), it ensures that the downstream equipment is truly and safely disconnected from the power source. This positive break in both lines offers a higher degree of safety assurance compared to single-pole switching.

Commercial Building Systems

Within commercial buildings, DPST switches find use in managing specific high-load circuits, such as large lighting arrays, commercial-grade kitchen equipment, or dedicated power circuits for specialized equipment. They can also be used to isolate entire sections of an electrical installation for maintenance or load management purposes. Their ability to handle substantial electrical loads reliably makes them suitable for the demands of commercial electrical infrastructure.

[Visual Suggestion: Insert high-quality photos showing DPST switches in various industrial, commercial, and appliance applications.]

The Buyer’s Advantage: Key Benefits of Using DPST Switches

For buyers specifying components for electrical systems, choosing a Double Pole Single Throw (DPST) switch offers several distinct advantages, particularly when dealing with demanding applications. Understanding these benefits reinforces why DPST is often the superior choice for safety, reliability, and compliance.

- Enhanced Safety:This is arguably the most significant benefit. By simultaneously disconnecting both poles (e.g., both live conductors in a 240V system, or live and neutral where required), DPST switches provide complete isolation of the downstream circuit or appliance. This drastically reduces the risk of electrical shock during maintenance, servicing, or in fault conditions compared to single-pole switching, which might leave one conductor energized. This enhanced safety is paramount in industrial, commercial, and high-power residential applications.

- Reliable High-Load Control:DPST switches are specifically engineered to handle the higher voltage and current levels associated with heavy electrical loads. Their internal components, contacts, and terminals are typically more robust than those found in standard single-pole switches. This ensures reliable operation without overheating or premature failure when controlling demanding equipment like large motors, heating elements, or industrial machinery. Buyers can trust DPST switches to manage significant power requirements dependably.

- Simplified Control:Despite controlling two circuits, a DPST switch provides a single point of actuation. This simplifies the user interface and operation compared to using two separate SPST switches that would need to be operated individually but ideally simultaneously. One flick of a lever or press of a button controls both circuits, reducing complexity and potential operator error.

- Code Compliance:In many jurisdictions, electrical codes mandate the use of double pole switching for specific applications, particularly for 240V appliances and as main isolation switches for equipment. Specifying a DPST switch ensures compliance with these safety regulations, avoiding potential issues during inspections and ensuring the installation meets legal safety standards.

- Durability and Robustness:Reflecting their common use in demanding environments, many DPST switches are built to higher durability standards. They often feature robust housings, reliable mechanisms, and materials designed to withstand the rigors of industrial or commercial use, leading to longer service life and reduced replacement costs.

These combined benefits make DPST switches a compelling choice for buyers prioritizing safety, reliability, and compliance when managing dual-circuit or high-power electrical control tasks.

Selecting the Right DPST Switch: A Buyer’s Checklist

Choosing the correct Double Pole Single Throw (DPST) switch is more than just finding a component that fits; it’s about ensuring safety, reliability, and optimal performance for your specific application. For buyers, navigating the various specifications can seem daunting. This checklist highlights the critical factors to consider when selecting a DPST switch to ensure you make an informed and appropriate choice.

- Electrical Ratings (Voltage & Current):This is paramount. The switch must be rated to handle the maximum voltage (measured in Volts, V) and current (measured in Amperes, A) of the circuit it will control. Always select a switch with ratings that comfortably exceed the normal operating parameters of your electrical load to provide a safety margin. Pay attention to whether the ratings are for AC (Alternating Current) or DC (Direct Current), as these can differ significantly for the same switch model. Overlooking ratings can lead to overheating, premature failure, or dangerous conditions.

- Actuation Type:How will the switch be operated? DPST switches come with various actuation Common types include:

- Toggle:A lever that is flipped up/down or left/right.

- Rocker:A pivoting button pressed on one side or the other.

- Push-button:Pressed to activate, may be momentary or latching (though DPST are typically latching ON/OFF).

- Rotary:Turned to select the ON/OFF position. The choice depends on the user interface requirements, space constraints, and the desired operational feel.

- Environmental Sealing (IP Rating):Consider the environment where the switch will be installed. Will it be exposed to dust, moisture, water splashes, or harsh chemicals? The Ingress Protection (IP rating) indicates the level of sealing against solids and liquids (e.g., IP65, IP67). Choose a switch with an appropriate IP rating to ensure longevity and prevent failures caused by environmental contamination.

- Operating Temperature Range:Switches have specified temperature ranges within which they can operate reliably. Ensure the selected DPST switch can withstand the minimum and maximum ambient temperatures expected in its installation location, whether it’s a hot engine compartment, a refrigerated area, or an outdoor setting.

- Certifications & Standards:For compliance and safety assurance, look for relevant certifications. Common marks include UL (Underwriters Laboratories), CE (Conformité Européenne), CSA (Canadian Standards Association), and RoHS (Restriction of Hazardous Substances). These certifications indicate that the switch has been tested and meets specific safety, quality, and environmental standards required in different regions or industries.

- Mounting Style:How will the switch be physically installed? Options include panel mount (through a cutout in an enclosure), DIN rail mount (common in control cabinets), surface mount, or PCB mount (directly onto a printed circuit board). Select the style that matches your mechanical design.

- Terminal Type:How will wires be connected? Common terminal types include screw terminals (wires secured by screws), solder lugs (wires soldered directly), or quick-connect/spade terminals (push-on connectors). Choose based on your assembly process and wiring preferences.

Carefully considering these factors will help you select a DPST switch that not only performs its function correctly but also ensures the long-term safety and reliability of your electrical system.

Unsure which DPST switch fits your needs? Download our Selection Guide or contact our technical experts today!

Installation & Safety Best Practices

While Double Pole Single Throw (DPST) switches are designed for enhanced safety, their effectiveness hinges on correct installation and adherence to proper procedures. Handling electrical components always carries inherent risks, and working with higher voltages or currents controlled by DPST switches demands particular caution. Following best practices is essential to ensure the safety of personnel and the reliable operation of the equipment.

- Emphasize Professional Installation:First and foremost, the installation of DPST switches, especially in mains voltage circuits or high-power applications, should always be performed by a qualified and licensed electrician. They possess the necessary training, knowledge of electrical codes, and experience to perform the installation safely and correctly.

- Correct Wiring:Proper wiring is critical. Ensure the LINE (input power) connections are made to the correct input terminals (e.g., L1, L2) and the LOAD (the device being controlled) is connected to the corresponding output terminals (e.g., T1, T2). Reversing connections or mixing poles can lead to malfunctions or dangerous situations. Always consult the switch ’s documentation and relevant wiring

- Secure Connections:Use the appropriate wire gauge for the current rating of the circuit. Ensure all wires are properly stripped and securely fastened to the switch terminals. Loose connections can cause overheating, arcing, intermittent operation, or complete failure, creating fire hazards or equipment damage.

- Grounding:Proper grounding is a fundamental safety requirement in electrical systems. Ensure the switch and associated enclosure or equipment are correctly grounded according to applicable electrical codes to provide a path for fault currents and reduce the risk of electric shock.

- Adherence to Codes:All electrical work, including the installation of DPST switches, must comply with local, national, and potentially international electrical codes and standards (e.g., NEC in the US, CEC in Canada, IEC standards). These codes dictate safe installation practices, required clearances, enclosure types, and more.

- Power Off:Never attempt to install or service a DPST switch while the circuit is energized. Always de-energize the circuit at the source (e.g., circuit breaker or main disconnect) and verify it is off using appropriate testing equipment before beginning work.

Disclaimer: The information provided here is for educational purposes only. Electrical installation and servicing must be performed by qualified personnel familiar with all applicable codes and safety procedures. Improper installation can result in serious injury, death, or property damage.

Frequently Asked Questions (FAQ) about DPST Switches

Here are answers to some common questions potential buyers and users have about Double Pole Single Throw (DPST) switches:

- Q1: Can a DPST switch control just one circuit?

- A: While a DPST switchis designed to control two circuits, you could technically use it to control just one by only connecting one pole (one input and its corresponding output terminal). However, this is generally not cost-effective or practical. If you only need to control one circuit, a simpler and usually less expensive SPST (Single Pole Single Throw) switch is the appropriate choice.

- Q2: Are DPST switches significantly more expensive than SPST switches?

- A: Generally, yes. Due to their more complex internal construction (two sets of contacts and a mechanical interlock) and often higher electrical ratings, DPST switchestend to be more expensive than their SPST counterparts with similar quality and ratings. However, the added cost reflects their enhanced capability and safety features, particularly for dual-circuit or high-power applications where they are necessary.

- Q3: What do typical terminal markings (L1, L2, T1, T2) mean on a DPST switch?

- A: These markings help ensure correct wiring. L1 and L2 typically represent the LINE or input connections for the two separate poles (where power comes infrom the source). T1 and T2 represent the corresponding LOAD or output terminals for each pole (where power goes out to the device being controlled). T1 is switched with L1, and T2 is switched with L2. Always refer to the ’s datasheet for specific terminal identification.

- Q4: How can I test if my DPST switch is functioning correctly?

- A: With the circuitsafely de-energized, you can use a multimeter set to continuity mode. Check continuity between L1 and T1, and separately between L2 and T2. In the OFF position, there should be no continuity (open circuit) across either pair. In the ON position, there should be continuity (closed circuit) across both pairs simultaneously. You should also check for isolation between the two poles (e.g., no continuity between L1 and L2, or L1 and T2) in both ON and OFF states.

- Q5: What is the difference between a DPST switch and a 2-pole circuit breaker?

- A: Both can interrupt two poles simultaneously, but their primary functions differ. A DPST switchis primarily for manual ON/OFF control. A 2-pole circuit breaker is primarily an automatic safety device designed to trip and interrupt the circuit automatically in response to overcurrent (overload or short circuit) conditions, although it can also be manually switched. While a breaker provides overcurrent protection, a DPST switch typically does not (unless it’s a specialized combination unit).

Your Partner for High-Quality DPST Switches

Navigating the specifications and selecting the ideal Double Pole Single Throw (DPST) switch requires careful consideration of your application’s unique demands, from electrical ratings and environmental conditions to safety standards and operational requirements. As we’ve explored, these switches are critical components for reliably controlling heavy loads, ensuring isolation in 240V circuits, and enhancing safety across industrial, commercial, and demanding residential settings.

At WEUP, we understand the importance of sourcing high-quality, reliable electrical components. We pride ourselves on offering a wide selection of DPST switches from leading s, backed by our technical expertise and commitment to customer satisfaction. Whether you need a robust switch for industrial machinery, a certified component for a commercial installation, or a dependable solution for a high-power appliance, our team is here to help you find the perfect match. We are dedicated to providing not just products, but solutions that ensure the safety, efficiency, and longevity of your electrical systems.

Ready to find the perfect DPST switch for your application? Browse our extensive catalog online, request a custom quote for specific requirements, or contact our knowledgeable sales team today for personalized assistance. Let us be your trusted partner for all your DPST switch needs.

| Voltage | Application |

| 12V | Automotive Electrical Systems UPS (Uninterruptible Power Supply) Solar Power Systems LED Lighting Portable Electronics |

| 24V | Automotive and Truck Applications Power Tools and Equipment Small Electric Vehicles Industrial Automation Equipment |

| 36V | Electric Bicycles and Scooters Power Tools Small Electric Vehicles |

| 48V | Electric Bicycles and Scooters Electric Vehicles (Light) Energy Storage Systems Power Tools |

| 110V-120V | Residential Power Systems Electronics Power Tools |

| 220V-240V | Commercial Power Supply Industrial Equipment Large Appliances |

Summary of Applications:

| Configuration | Applications |

|---|---|

| ON OFF | Ligh |

| ON ON | Circuit selecti |

| ON OFF ON | Fan spee |

| (ON) OFF ON | Vehicle |

| (ON) OFF (ON) | Motor direc |

Features

After selecting the voltage, you can choose the specific switch type for your application.

| Switch Type | Features |

Rocker Switch Rocker Switch | A rocker switch features a pivoting mechanism for on/off control, is durable, easy to operate, and comes in various configurations, sizes, and designs, suitable for both residential and industrial applications. |

Toggle Switch Toggle Switch | A toggle switch has a lever that moves up and down to control electrical circuits. It offers a reliable on/off mechanism, comes in various sizes, and is commonly used in industrial and household devices. |

Electromagnetic Switches Electromagnetic Switches | Electromagnetic switches use an electromagnet to control the opening and closing of circuits. They offer precise, remote operation, are commonly used in relays, solenoids, and automated systems for efficient switching. |

Micro Switch Micro Switch | A micro switch is a small, highly sensitive switch activated by minimal physical force. It provides precise, reliable operation in response to motion, commonly used in safety devices, appliances, and machinery controls. |

Push Button Switch Push Button Switch | A push button switch is a simple on/off mechanism activated by pressing a button. It is compact, easy to operate, and widely used in electronics, appliances, and control panels for various applications. |

Tactile Switches Tactile Switches | Tactile switches provide feedback through a slight “click” when pressed, offering a reliable and responsive action. Compact and durable, they are commonly used in electronic devices, keypads, and control panels. |

Related Resources

Single Pole Single Throw (SPST) Switch