What is a Custom Rocker Switches?

A custom rocker switch is a specially designed electrical switch that is tailored to meet specific requirements, preferences, or specifications outlined by a customer. These switches are customized in terms of their design, features, dimensions, and functionalities to fit the unique needs of a particular application or industry.

Custom Rocker Switches

With Full Product Certification

Customized in a Rocker Switch

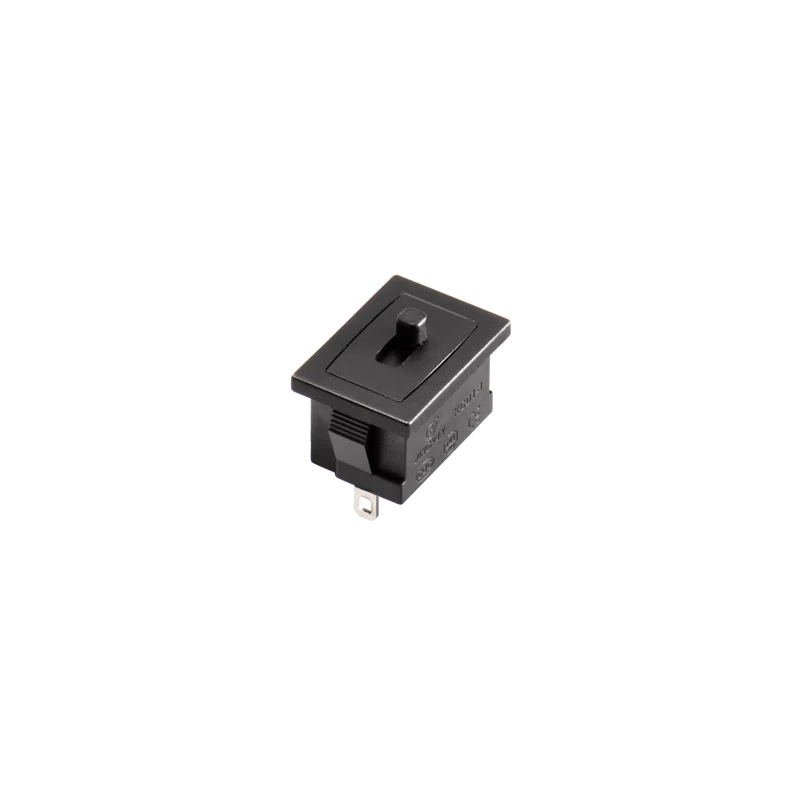

The physical appearance of the rocker switch, including its shape, size, and color, can be customized to match the aesthetic or branding requirements.

Custom rocker switches can be designed to handle specific current and voltage ratings according to the electrical specifications of the application.

For applications exposed to harsh environments, custom rocker switches can be designed with specific sealing and environmental protection features, such as water resistance or dustproofing.

Custom rocker switches may include illumination features, such as LED indicators, for visual feedback on the switch status. The color and intensity of the illumination can be customized.

Custom rocker switches may include illumination features, such as LED indicators, for visual feedback on the switch status. The color and intensity of the illumination can be customized.

The materials used in the construction of the switch can be chosen based on the environmental conditions and durability requirements of the application.

Custom rocker switches can include logos, symbols, or branding elements that align with the customer’s brand identity.

Custom rocker switches can be designed and manufactured to meet specific industry standards and certifications, ensuring compliance with safety and regulatory requirements.

Customization can include specific mounting options (panel mount, snap-in, etc.) and terminal configurations that suit the installation needs.

Custom Rocker Switch Cover

custom rocker switch cover is a personalized or specially designed cover for rocker switches, typically used in various settings like vehicles, boats, machinery, and electronic panels. These covers are not just functional components; they also offer an opportunity for customization and personalization.

Advantages and Disadvantages of Custom Switches

- Tailored to Application Needs:

- Custom switches can be designed to precisely match the requirements of a specific application, ensuring optimal performance and functionality.

- Optimized Performance:

- Customization allows for fine-tuning electrical specifications, materials, and features to achieve the best possible performance in a given environment.

- Unique Features and Functions:

- Custom switches can incorporate special functions or features that may not be available in standard switches, providing a competitive edge.

- Aesthetic Customization:

- The appearance of custom switches can be tailored to match the overall design and branding of the product, contributing to a cohesive and visually appealing product.

- Compliance with Standards:

- Custom switches can be designed to meet specific industry standards and regulatory requirements, ensuring compliance and safety.

- Enhanced Durability:

- By selecting materials and construction methods based on the application’s demands, custom switches can be more durable and have a longer lifespan.

- Application-Specific Size and Mounting:

- Customization allows for the selection of optimal size and mounting options, ensuring seamless integration into the product or system.

- Flexibility for Future Changes:

- Custom switches can be adapted to changes in technology or application requirements, providing long-term flexibility.

- Higher Upfront Costs:

- Customization often involves higher upfront costs for design, tooling, and manufacturing, which can impact the initial budget.

- Longer Lead Times:

- Developing custom switches may take more time compared to sourcing off-the-shelf switches, potentially delaying the product development timeline.

- Limited Availability:

- Custom switches may have limited availability, making it challenging to replace or upgrade components in the future.

- Expertise Required:

- Designing custom switches requires expertise in electrical engineering, manufacturing, and compliance standards, which may not be readily available in all organizations.

- Complexity in Supply Chain:

- Custom switches can introduce complexity into the supply chain, particularly if specialized components are needed.

- Risk of Over-Engineering:

- In some cases, customization might lead to over-engineering, where features or specifications exceed actual application requirements, potentially increasing costs unnecessarily.

- Potential Compatibility Issues:

- Custom switches may pose compatibility challenges with other components or systems, especially if not well-integrated into the overall design.

- Market Acceptance:

- The market might have established preferences for certain standard switches, and introducing custom switches may require additional marketing efforts.

Find more related articles

.jpg)

equip yourself with the knowledge shared in this article to smoothly rock your way towards an optimal electrical solution! how does rocker switch work

.jpg)

Discover why thermoplastic is a top choice for rocker switches and the benefits it provides. WEUP Rocker Switches manufacturer! Get all the details here!

.jpg)

Discover the secret behind how rocker switches bring life to your home appliances. Unleash their power and revolutionize the way you experience convenience! WEUP Rocker Switches manufacturer!

Related Product

Custom Rocker Switch FAQs

Custom rocker switches, often used in a variety of applications from automotive to marine to industrial settings, offer a tailored control solution. Here are some frequently asked questions about custom rocker switches:

Custom rocker switches are switches that can be customized in terms of design, functionality, labeling, and size to fit specific needs and applications. They are commonly used where standard switches do not meet all the requirements.

Yes, one of the main features of custom rocker switches is the ability to have personalized labels. This is particularly useful for clarity in control panels with multiple switches.

Absolutely. They can be designed in various sizes to fit specific panels or spaces.

Custom functionalities can include different switching actions (like momentary or maintained), varying electrical ratings, and the inclusion of LED lights for status indication.

Yes, many custom rocker switches are designed to be waterproof or water-resistant, making them ideal for marine, outdoor, or industrial applications.

Consider the environment (e.g., wet, dusty), electrical requirements (e.g., voltage, current), mounting style, and the specific function of the switch. Consulting with a manufacturer or an expert can be very helpful.

Yes, they often come with options for backlighting or indicator lighting, which can be customized in color and intensity.

Yes, they can have different types of actuation like single throw or double throw, and the actuation force can also be customized.

Wiring depends on the specific type and functionality of the switch. It’s important to follow the manufacturer’s wiring diagram and instructions.

They can be made from a variety of materials, including plastics, metals, and rubber for waterproofing.