Introduction

Perhaps you’ve been overwhelmed by the various types of mechanical switches on the market, not knowing exactly which type you have in hand, or how to choose the right mechanical switch to match various applicatioins. This article will fully explain what a mechanical switch is, what types of mechanical switches there are, and how to choose the appropriate mechanical switch.

Differences between Mechanical and Electrical Switches

Differences between Mechanical and Electronic Switches

When talking about switches, we should also mention that there are two main categories in the world of switches: one is the mechanical switch, also known as an electrical switch, which is the subject of this article; the other is the electronic switch.

Simply put, mechanical switches (or electrical switches) require manual or physical actions (such as moving, pressing, releasing, or touching) to perform the switching action. Electronic switches, on the other hand, control the switching action using semiconductor devices like transistors. Therefore, all switches that require manual operation are considered mechanical switches, while those that do not require manual operation are electronic switches.

Classification of Mechanical Switches

Mechanical switches can be further classified based on the number of contacts, actuation method, number of poles and throws, and operating methods, which is the main purpose of this article: to teach you how to identify the types of mechanical switches. Some popular types of mechanical switches include pushbutton switches, toggle switches, rocker switches, touch switches, slide switches, voltage selector switches, and refrigerator switches.

Classification of Electronic Switches

Electronic switches, also known as solid-state switches, do not have moving parts or physical contacts. Some examples of electronic switches include power diodes, MOSFETs, and SCRs. Other electronic switches include GTOs, DIACs, TRIACs, and IGBTs.

Types of Mechanical Switche

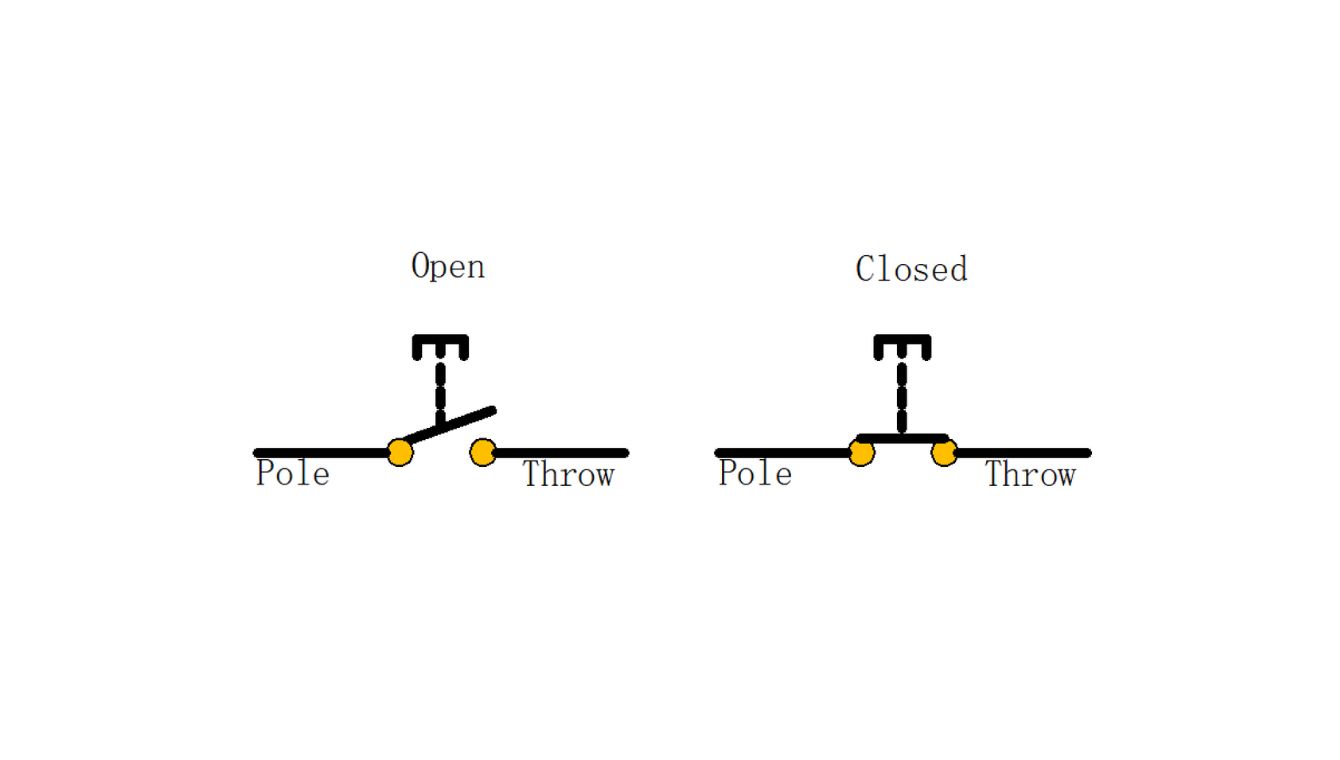

SPST Switches

As the most familiar and simplest type of basic mechanical switch, the SPST switch is often referred to as a “One Way” or “Single Way” single-pole single-throw switch, featuring simple ON and OFF functions. This type of switch contains one input contact and one output contact, mainly used in household lighting, small load appliances, and electronic devices such as computers. It can control a single operation in the circuit, that is, by connecting or disconnecting to control the power supply of the circuit.

Typically, the contacts of an SPST switch can be in the OFF position under a Normally Open (NO) state, or in the ON position under a Normally Closed (NC) state. When the circuit is closed, i.e., in the ON position, it indicates that current is flowing and the circuit is powered. When the circuit is open, i.e., in the OFF position, it indicates that the current is interrupted and the circuit is powered off.

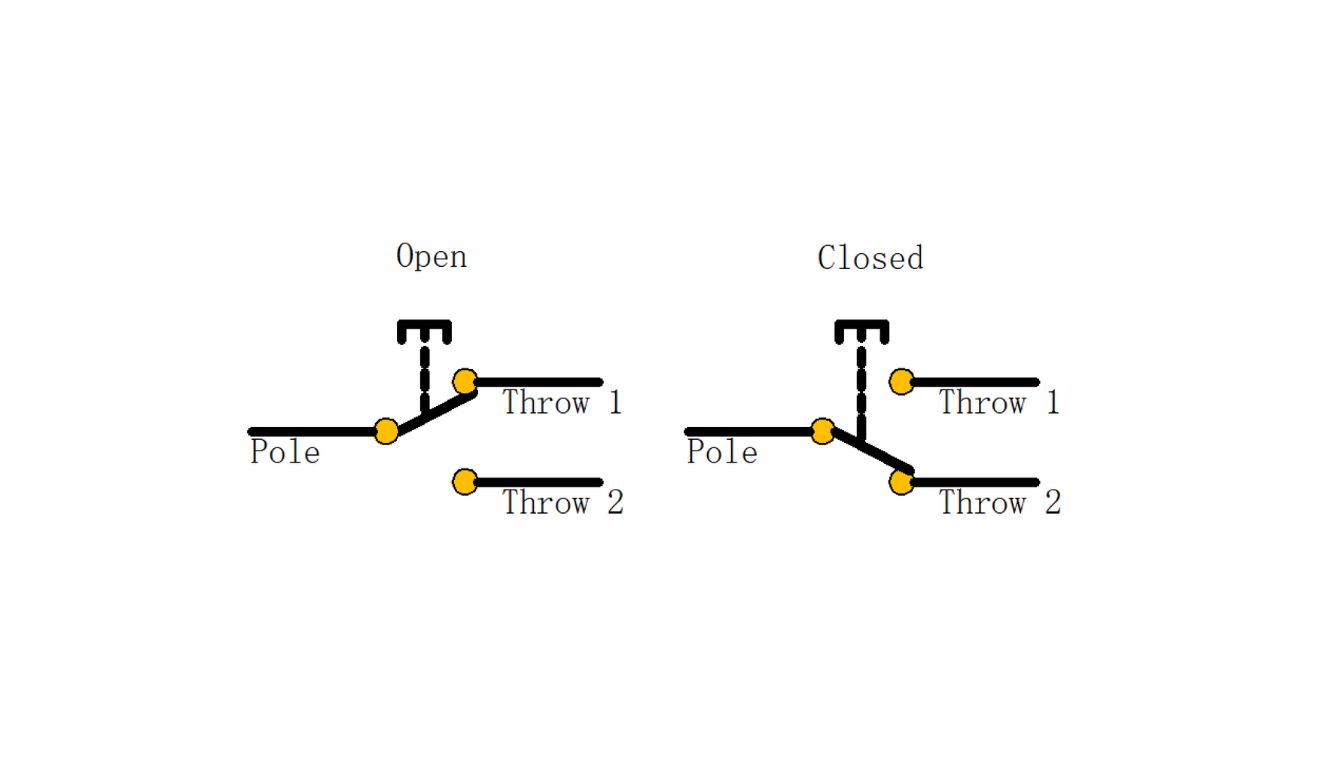

SPDT Switches

SPDT switch, also known as Single Pole Double Throw or Selector switch, has three terminals and an additional ground terminal. One terminal serves as the common input terminal, while the other two are the output terminals, also known as travelers. This switch is designed with two ON positions and one OFF position, allowing for switching between one input and two different output selections, thereby enabling control of two circuits simultaneously. In many circuit applications, SPDT switches are widely used for selectively providing current or signals to two loops using their switching function. In the United States, this type of two-way switch is also known as a three-way switch.

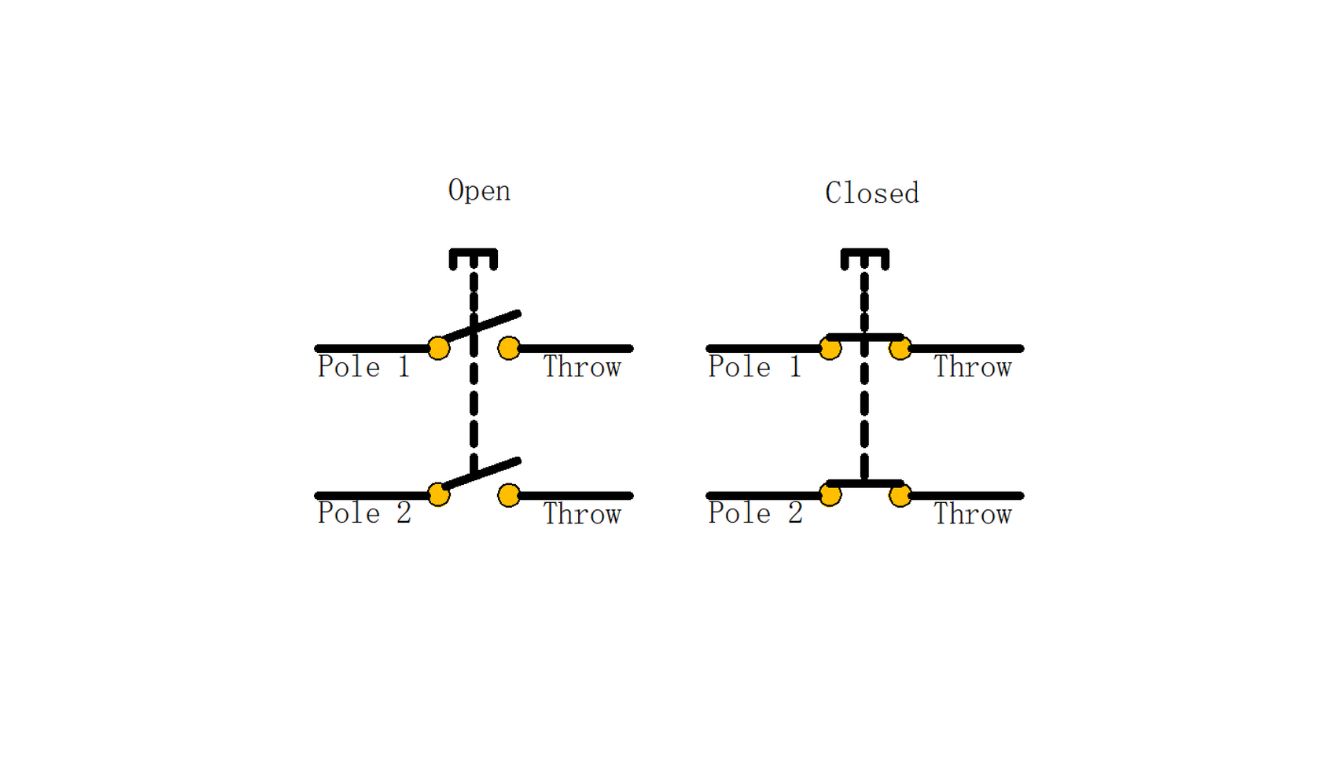

DPST Switches

Double-Pole Single-Throw (DPST) switches are equivalent to a combination of two Single-Pole Single-Throw (SPST) switches and can control two independent circuits. It operates both circuits simultaneously with a common actuator lever, having four terminals: two input terminals, and two output terminals. The output terminals can be either normally open or normally closed.

DPST switches are widely used in situations where it is necessary to control the switching on and off of two circuits at the same time, such as connecting or disconnecting the power supply and ground wires simultaneously. Their working principle is similar to that of double-pole circuit breakers. DPST switches ensure the safety and effective operation of circuits, especially in applications where it is necessary to cut off or connect both the power line and the neutral line simultaneously.

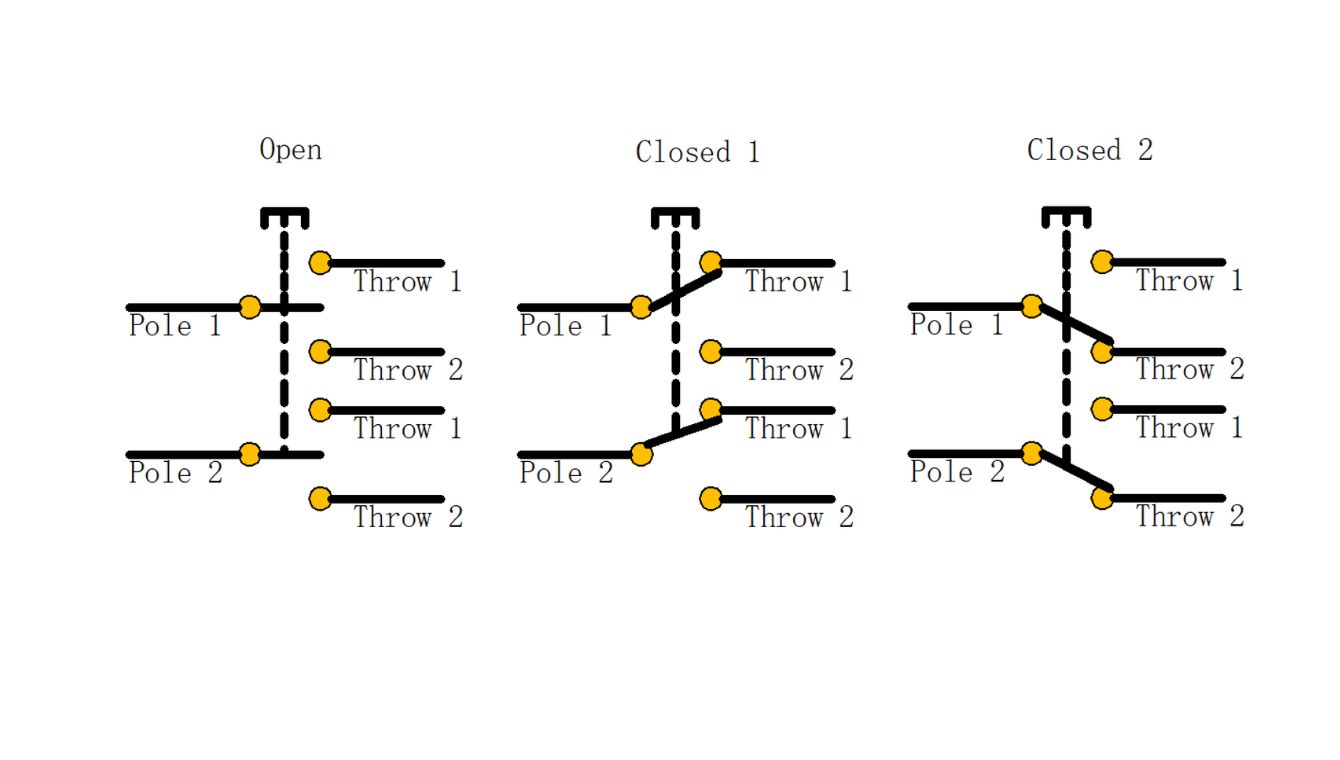

DPDT Switches

A DPDT (Double-Pole Double-Throw) switch is a type of switch that can control two independent circuits simultaneously, integrating the functions of two SPDT (Single-Pole Double-Throw) switches. This switch is designed with two stable ON positions, acting like a bidirectional ON/OFF switch. A DPDT switch has six terminals, including two input terminals, which are the two poles, and two sets of output terminals connected to each pole, making a total of four throw terminals.

When using a DPDT switch, the operator can change the connection state of the circuits by moving the lever to a different position. In one position, each of the two input terminals is connected to one set of output terminals. When the lever is switched to another position, the same input terminals will then be connected to the other set of output terminals. This design makes the DPDT switch very suitable for applications that require controlling the on or off state of two circuits at the same time. Although the DPDT switch uses a single control lever, it can independently open or close operations for each circuit.

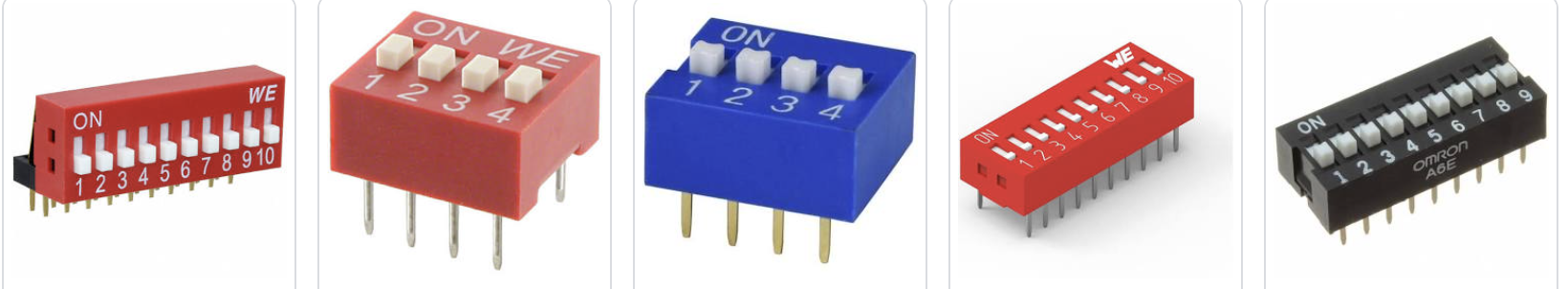

DIP Switches

DIP (Dual In-line Package) is a type of packaging for electronic components that integrates multiple electrical switches within a compact housing. This design makes it very useful in electronic prototyping, especially when assembling and testing circuits on a breadboard and printed circuit board (PCB). The arrangement of DIP switches allows them to be directly inserted into a breadboard or soldered onto a PCB, facilitating rapid iteration and modification of circuit designs.

Among the different implementations of DIP, electromechanical versions and digital versions are two common types. Electromechanical versions of DIP switches require the user to manually move an actuator to switch between the ON or OFF states, and these types of switches are suitable for situations where settings do not need to be changed frequently. Digital versions of DIP switches can respond to electronic signals and change states automatically, such automation in switching functions makes them play an important role in complex circuits or applications that require rapid switching based on program control.

Toggle Switches

Toggle switches are a common type of electrical switch that controls the connection and disconnection of circuits through manual manipulation of a mechanical lever or rocker. These switches have a latching feature, meaning they maintain their given state, either connected or disconnected, without the need for external force. Toggle switches come in a variety of designs, from simple Single-Pole Single-Throw (SPST) to more complex Double-Pole Double-Throw (DPDT) configurations, to meet different circuit control requirements.

These switches are not only widely used in household lighting control but can also handle applications with different current levels, up to and exceeding 30 amperes. The rated values, physical dimensions, and design styles of toggle switches vary according to their role and required functionality in specific circuits, ensuring both electrical safety requirements are met and suitability for various applications.

Rocker Switches

Rocker switches are electrical components that control the flow of current through a lever that can switch between two positions, hence their name “switch.” In their design, the switch has two fixed positions, “on” and “off,” which intuitively indicate the current working status. When the switch is in the “off” position, the circuit is interrupted, and the current cannot flow to the load; conversely, in the “on” position, the circuit closes, allowing the current to flow smoothly to the target device. Rocker switches are not only convenient and intuitive to use but are also widely used in household appliances, automobiles, industrial, and electronic devices.

In terms of wiring, rocker switches typically have three terminals: common terminal (COM), normally open terminal (NO), and normally closed terminal (NC). The common terminal connects to the power line, while the NO and NC terminals are used to connect the load as needed. If power needs to be supplied to the load when the switch is “on,” the power line should be connected to the COM terminal and the load line to the NO terminal; conversely, the load line should be connected to the NC terminal. Additionally, when choosing a rocker switch, factors such as voltage and current specifications, durability, and environmental considerations should be taken into account to ensure the best combination of safety and efficiency.

Rotary & Selector Switches

Rotary and selector switches are multi-position switches that control a common terminal connected to different circuits through a rotating action. These switches are common in situations where selective control of multiple circuits is needed, such as setting specific operation times or options. Their internal mechanism is similar to the rotary switch of a multimeter, relying on physical rotation to change the connection state of circuits and select different signal channels. This mechanical action is achieved by rotating a knob, thereby switching the connections between different output terminals and a common terminal.

The design of selector switches allows for multiple configurations to meet the needs of electrical systems with varying complexities. For example, they can be designed in different structural forms such as single-pole 12-throw (1P12T), double-pole six-throw (2P6T), triple-pole four-throw (3P4T), and four-pole three-throw (4P3T). Each structure contains a corresponding number of movable contacts and fixed contacts that connect or disconnect in sequence under the drive of the knob, thus achieving precise control over multiple circuits or functions.

Push Button Switches

Push button switches utilize the momentary characteristics of a spring mechanism to quickly connect and disconnect a circuit. When the user applies pressure to the button, the movable contact inside the switch rapidly connects to the stationary contact, thus closing the circuit and achieving an ‘ON’ state. As soon as the pressure is released, the spring mechanism immediately retracts the movable contact, and the circuit opens, returning to the ‘OFF’ state. This type of switch is commonly used in situations where temporary control of the electric current is required, such as the brief ringing of a doorbell.

Depending on different requirements, push button switches can be designed as normally open, normally closed, or double-action types. Normally open push button switches remain open when not pressed, while normally closed types are the opposite; double-action push button switches can control two independent circuit systems at the same time. Such switches are widely used in various devices, for example, an electric drill that uses a normally open push button switch starts working when the user presses the button, or a blower that uses a normally closed push button switch stops running when the button is released.

Micro Switches

Micro switches, also known as snap-action switches, are a type of electrical switch operated by mechanical means. They use a spring-loaded lever to open and close the contacts inside the unit. These switches are designed with three main terminals: common terminal, normally closed terminal, and normally open terminal. In the static state of the micro switch, the power is connected to the common terminal and energy is transferred through the spring touching the normally closed terminal. When the lever is moved, the power is switched to the normally open terminal, completing the circuit change.

Micro switches are widely used in the safety field due to their high reliability and low cost, especially in situations where interrupting a circuit is needed to prevent machines from starting or to ensure that doors cannot close when there is an obstacle. They are used in a wide range of applications from household appliances to industrial equipment, such as door interlocks in microwave ovens, leveling adjustments in vending machines, and door safety switches in elevators. Additionally, micro switches can be designed to be extremely sensitive for use in precision equipment that requires high-precision detection of gas flow and other variables.

Limit Switches

Limit switches are a type of electrical switch designed with a bumper-style arm that can respond to physical contact or pressure to manipulate a circuit. In some automated equipment like washing machines, this switch can detect the position and motion of mechanical parts, thus ensuring the machine starts, stops, or switches operation modes at the correct times. The switch can be directly pushed by mechanical motion, or it can be manually operated to allow precise control of the circuit in different situations.

Among various limit switches, the button limit switch is the most common type, which activates or cuts off the circuit when triggered by an object or part of the equipment. More complex are double limit switches, which come equipped with dual functions that can control two separate circuits simultaneously, enabling one circuit to be disconnected while another is connected. Such switches are particularly useful in situations where complex control logic is needed.

Relay Switches

Relay switches are electromagnetic devices that can control a large current with a smaller current. Their operating principle is to use the electromagnetic field generated by a coil to make the switch contact close or open, thereby controlling high-voltage circuits. This unique function allows relays to control complex or high-power circuits with only a weak signal and is also widely used in scenarios where one signal needs to control multiple circuits.

Another key role of relays is to act as a protective device, ensuring complete isolation between low-voltage and high-voltage circuits, especially in power systems, where relays can detect faults and cut off circuits to prevent damage. Different types of relays, such as solid-state relays (SSR), electromechanical relays (EMR), and others, have different switching characteristics based on application requirements, such as SSRs which can achieve instant-on, zero-cross switching, or analog signal control, among other functions.

Intermediate Switches

Intermediate switches are a special type of electrical switch commonly used for the control of a single electrical device from multiple locations. They allow users to control lighting devices, such as those at the top and bottom of a staircase, from two different places. This type of switch has four terminals, allowing the current to switch between two control points, thus enabling remote control of the electrical device.

In different regions, intermediate switches are known by different names. In the American market, they are called four-way switches, while in the UK and the EU they are usually referred to as three-way switches. The design of this switch makes it very suitable for lighting control in staircases, long corridors, or rooms with multiple entrances, simplifying the complexity of operating a single circuit across multiple locations. Additionally, intermediate switches are also known as crossover switches or cross switches, these names all refer to their ability to switch the current path between different control points.

Flow Switches

Flow switches are monitoring devices specifically designed to sense and respond to the flow of liquids or gases in a piping system. In gas applications, the device typically employs a rapid-acting mechanism, which includes a metal arm connected to a microswitch and a vane-like sensor element mounted on the arm. When the intensity of the airflow reaches a certain level, the force of the gas moves the sensor element and its connected metal arm, thereby triggering the microswitch to close or open the electrical contacts. This action changes the state of the circuit, thereby controlling the system or providing a signal indication.

On the other hand, flow switches also play a crucial role in liquid media. They perform their monitoring task by detecting whether the flow rate of the medium being transmitted through the pipeline exceeds predetermined limits. When the flowing liquid or gas reaches or exceeds the set threshold, an internal spring mechanism is activated, pushing the connected microswitch. Such design not only enables real-time monitoring of flow rates but also allows for a quick response in case of flow anomalies, ensuring safe operation of the system or adjusting as needed. Flow switches come in two basic types: normally closed and normally open, and are widely used in various fluid control systems such as pipelines and storage tanks.

Float Switches

Float switches utilize the principle of buoyancy to achieve precise control of liquid levels. Inside a water tank or other container, the float rises or falls with the change in liquid level. This vertical movement mechanically activates an electrical switch, thereby controlling the opening and closing of the circuit. When the liquid level drops to a set limit, the float, through a linkage, causes the switch to close, starting the pumping system. Conversely, when the liquid rises to the upper limit, the system cuts off the power supply through the float switch, stopping the pump.

These switches are widely used in the field of automation control, particularly playing a key role in liquid level monitoring and management. They not only protect equipment from damage and prevent liquid spillage but also save energy and optimize workflows by automatically controlling the operation of pumps. Due to their simple structure, reliable operation, and easy maintenance, float switches have become an indispensable part of industrial and household equipment.

Pressure Switches

Pressure switches are devices widely used in industrial environments, specifically designed to monitor and regulate pressure within a system. These switches can detect whether the pressure of liquids, air, or gases has reached a predefined threshold and respond accordingly. When the detected pressure exceeds or falls below this threshold, the pressure switch triggers a series of actions that open or close electrical contacts, thereby changing or controlling the operating state of the system. They are essential for ensuring the proper functioning of pneumatic equipment and hydraulic systems, as these systems rely on precise pressure control to maintain stability and efficiency.

In terms of construction, pressure switches can take various forms, including designs with metal bellows, pistons, and diaphragms. These different types of pressure switches are used to detect pressure changes with varying ranges and precision based on application requirements. Metal bellows-type pressure switches are suitable for high-precision pressure detection, while piston and diaphragm types are more appropriate for rough or medium precision pressure monitoring in industrial environments. Single-pole and double-pole describe the configuration of their electrical contacts, with single-pole switches controlling one circuit and double-pole switches controlling two circuits, selected based on the different needs of the application.

Joystick switches

Joystick switches are multi-directional control devices whose core component is a lever that can move freely in all directions. Each movement direction of the lever—up, down, left, right—is connected to the contacts of the switch, and when the operator pushes the lever, the corresponding circuits are connected or disconnected, thus allowing for precise control over mechanical or electronic equipment. This flexible switch design enables operators to easily control equipment as needed.

Such switches are widely used in fields that require multi-dimensional control inputs, such as game controllers, operating levers for construction machinery, handheld remote devices, and stabilizer controls for photography equipment. In heavy machinery like trucks, excavators, and cranes, joystick switches provide an intuitive control method that can precisely manipulate machinery for complex tasks, such as the delicate handling of cargo or operations in tight spaces.

Temperature & Thermal Switches

Temperature switches rely on the principle of thermal expansion and contraction in physics to control the opening and closing of circuits. Within the circuit, a bimetallic strip acts as the key temperature-sensitive element, which deforms with changes in temperature. When the ambient temperature rises to a certain preset threshold, the bimetallic strip bends due to thermal expansion, causing it to separate from the circuit’s contacts, thus breaking the circuit. This process is automatic, ensuring that when electrical equipment overheats, the power is promptly cut off to prevent damage.

When the temperature drops, the bimetallic strip contracts due to cooling and returns to its original state, causing the contacts to close and the circuit to reconnect. This self-resetting characteristic makes the bimetallic strip very effective in temperature control protection. Different types of temperature switches, such as normally closed (NC) and normally open (NO), close or open circuits under specific conditions according to their functional requirements. They are widely used in various types of electrical equipment, such as mercury-in-glass thermometers and thermal relays, mainly for monitoring and protecting motors from damage due to overload.

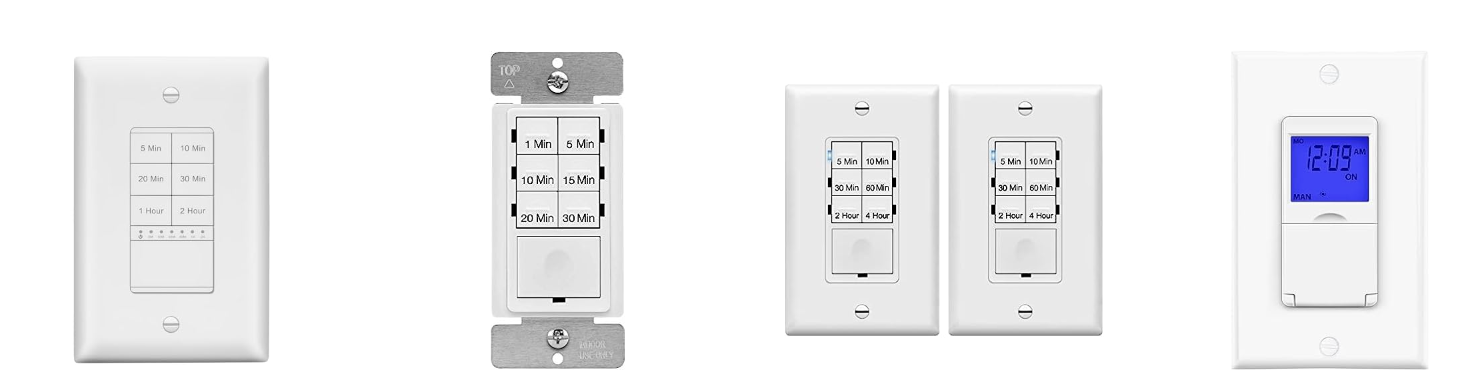

Timer switches

Timer switches are a type of switch device based on time control, capable of automatically switching the circuit state at specific times set by the user to connect or disconnect the electrical load. Their operation involves the measurement of preset time, and once the predetermined time is reached, the built-in mechanism triggers the corresponding operation. Digital timers and analog timers are the two common forms of these switches, each using different technological means to achieve time control functions to cater to various delay requirements.

In practical applications, mechanical timers complete the countdown through a spring mechanism, and after the time elapses, they change the contact state through physical actions to control the connected circuit. This type of timer switch is widely used in both life and industrial fields, such as being used in conjunction with contactors and relays for the control of power systems, timing start/stop of water heaters, automatic regulation of home heating systems, and timing functions for personal use in vehicles and household televisions, demonstrating the widespread importance of timer control technology in daily life.

Inclustion

As you can see, there are many types of mechanical switches. In this article, we have provided you with a detailed introduction to various types of mechanical switches, including their working principles, classification methods, and applications in different fields. We hope that through this in-depth understanding, you are now able to fully distinguish the types and characteristics of mechanical switches. In summary, whether in household appliances, industrial equipment, or electronic products, choosing the right mechanical switch is crucial. We hope this article can help you better understand how to choose the appropriate mechanical switch to meet your needs.