Just as a conductor guides the orchestra to harmonious synchronization, the National Electrical Code (NEC) governs electrical installations within the United States, ensuring safety and efficiency. This article delves into the impact of NEC on power tool switch installation. Illuminating the intricate nuances of the NEC, its application in understanding power tool switches will be explored. The focus will be placed on NEC requirements for power tool switch installation along with wiring methods. In addition, common mistakes to avoid while complying with these standards will be highlighted. A comprehensive analysis of benefits that stem from adhering to NEC guidelines concludes this exploration. This discourse aims not only to inform but also equip readers with practical knowledge about power tool switch installations under NEC regulations.

Introduction Power Tool Switch Installation

The National Electrical Code (NEC), established by the National Fire Protection Association, provides a comprehensive set of standards aimed at ensuring safe electrical installations across various settings. Compliance with the NEC is integral to maintaining safety and efficiency in electrical installations, thus reducing potential hazards linked with improper installation or use. In particular, correct power tool switch installation as per NEC guidelines plays a crucial role in preventing accidents and enhancing utility value, clearly illustrating the practical implications of this regulatory framework.

The National Electrical Code (NEC) and its purpose

Established primarily to safeguard lives and properties against potential hazards arising from improper electrical installations, the National Electrical Code (NEC) serves as a critical regulatory benchmark governing all aspects of electrical work, including power tool switch installation.

The NEC is instrumental in:

- Setting forth clear and stringent national standards for all types of electrical wiring projects, thereby ensuring electrical requirements are met.

- Promoting installation safety requirements which help reduce risks associated with power tool switch installation.

- Dictating minimum standards that must be adhered to by professionals in the field, hence enhancing overall safety.

- Providing guidelines that aid in minimizing any chances of electrocution or fire outbreaks due to faulty wiring.

In essence, the NEC plays an integral role in shaping safe and efficient power tool switch installations across various domains.

Importance of compliance with the NEC for electrical installations

Adherence to the guidelines set forth by NEC proves vital for ensuring safety in all aspects of electrical work, akin to a lighthouse guiding ships safely to shore amidst potentially treacherous conditions. The importance of compliance with the NEC cannot be overstated, particularly when dealing with power tool switch installation.

The table below highlights key points regarding why it’s essential to adhere to NEC standards:

| Importance | Effect |

|---|---|

| Safety | Prevents electrical accidents |

| Reliability | Ensures consistent performance |

| Regulation adherence | Avoids legal penalties |

Invariably, any deviations from these national electrical code regulations during electrical installations can lead to unsafe situations and potential regulatory repercussions. Hence, strict compliance with the NEC is critical for maintaining both safety and functionality in every aspect of electricity usage.

Significance of proper power tool switch installation

Ensuring the correct setup of machines with high-energy output, such as those utilized in construction and manufacturing processes, holds paramount significance for both operator safety and equipment functionality. The national electrical code provides a comprehensive framework for power tool switch installation that ensures the safe operation of these devices.

- It minimizes risks associated with improper connection or damage to the electrical circuit.

- Complying with codes guarantees standardized practices across different regions, promoting uniformity in safety measures.

- A correctly installed switch can prevent possible electrocution or fire hazards.

- Proper setup also aids in maintaining the device’s longevity by preventing undue stress on its components.

- Lastly, it instills confidence amongst operators about their safety while using these tools.

Thus, understanding the significance of proper power tool switch installation is essential in any high-energy output environment.

Understanding the National Electrical Code (NEC)

The National Electrical Code (NEC) boasts a rich history, having been established in the 1890s with the primary purpose of standardizing electrical safety measures across different jurisdictions. Crucial organizations such as the American National Standards Institute and the National Fire Protection Association play integral roles in its development and maintenance, ensuring it reflects modern electrical practices. Covering an extensive range of areas related to electrical installations and equipment, the NEC undergoes regular updates and revisions to keep pace with technological advancements, providing comprehensive guidelines that influence power tool switch installation among other applications.

Brief history and purpose of the NEC

Established in 1897, the National Electrical Code (NEC) serves as a fundamental guideline for electrical installation procedures across the United States, with its key purpose being to safeguard people and property from potential electrical hazards. This includes power tool switch installation, among others. The NEC was introduced by the National Fire Protection Association (NFPA), with an aim to provide a standardized set of rules that ensures safe practices during design, installation and inspection of electrical equipment. The brief history and purpose of the NEC have been instrumental in reducing risks related to electricity use. By encapsulating principles pertinent to various aspects like power tool switch installations, it continues to guide electricians towards safer operations while providing a harmonized approach for mitigating electrical risks nationwide.

Key organizations involved in developing the NEC

In the realm of electrical safety, prominent organizations such as the National Fire Protection Association (NFPA) and the American National Standards Institute (ANSI) play pivotal roles in drafting and refining the guidelines encapsulated within the NEC. These institutions ensure that manufacturers, including power tool switch manufacturers, adhere to strict safety standards throughout production.

The following table illustrates how these entities impact various stages of power tool switch production:

| Stages | NFPA Role | ANSI Role |

|---|---|---|

| Designing | Ensures designs meet NEC requirements | Reviews designs for standard conformity |

| Manufacturing | Monitors manufacturing processes among power tool switch china factories | Ensures adherence to safety standards among power tool switch china vendors |

| Distribution | Regulates distribution channels for power tool switch suppliers | Certifies quality control practices amongst power tool switch china vendors |

| Installation & Usage | Provides installation guidelines for users and professionals alike | Sets usage standards to prevent electrical hazards |

Thus, NFPA and ANSI contribute significantly towards maintaining electrical safety in the realm of power tool switches.

Scope and coverage of the NEC

Covering a substantial range of electrical installations, the scope of NEC encompasses diverse areas such as residential, commercial and industrial systems. The National Electrical Code (NEC) is an essential document that governs the installation and maintenance of these electrical systems, including power tool switch installation.

- Residential Systems: NEC provides guidelines for safe installation of electrical systems in homes.

- Commercial Systems: It also covers rules for power installations in businesses and commercial establishments.

- Industrial Systems: Industrial settings have unique needs, and the NEC outlines standards for these environments too.

- Qualified Person Requirement: The code stipulates that only a person who has skills and knowledge related to the construction and operation of electrical equipment should perform installations.

The scope and coverage of the NEC ensure safety across all types of electrical systems installations.

Updates and revisions to the NEC

Regular revisions and updates ensure that the NEC remains a dynamic and responsive resource, accommodating technological advancements and emerging trends in electrical systems. Power tool switch manufacturers are directly influenced by these changes as they modify their designs to comply with the updated national electrical code. The code revisions also alter the procedures for power tool switch installation, necessitating technicians to adapt to new methods of installations. The updates and revisions to the NEC reflect the latest safety standards and best practices within the industry, inherently shaping power tool manufacturing processes. Hence, each revision of this electrical code significantly impacts how power tools switches are designed, installed, and used, reinforcing its relevance in maintaining safe conditions in residential, commercial, or industrial settings.

Understanding Power Tool Switches

Understanding power tool switches is pivotal to electrical safety, emphasizing the significance of their function in controlling the flow of electricity and subsequently safeguarding users from potential hazards. The exploration of different types of power tool switches often used highlights a diverse spectrum which includes push-button switches, toggle switches and trigger switches among others, each possessing unique characteristics that cater to specific applications. This comprehensive understanding not only facilitates effective use but also aids in ensuring adherence to established safety guidelines.

Power tool switches and their significance in electrical safety

Power tool switches, akin to the gatekeepers of electrical safety, play an indispensable role in preventing accidental start-ups and protecting users from potential electrical hazards. As a fundamental component of every power tool, the switch ensures control over the machine’s operation.

- Power Tool Safety Switch: An effective power tool safety switch prevents unintentional activation, thereby reducing potential accidents.

- Power Tool Switch Manufacturer: Manufacturers are obliged to adhere to stringent standards set by the National Electrical Code when designing and installing these switches.

- Electrical Safety: Strict compliance with these codes guarantees optimal electrical safety for end-users.

- National Electrical Code: This regulatory framework governs all aspects of power tool switch installation, ensuring not only user protection but also improved efficiency of power tools.

Thus, understanding these facets can significantly enhance awareness about responsible usage and maintenance of power tools.

Different types of power tool switches commonly used

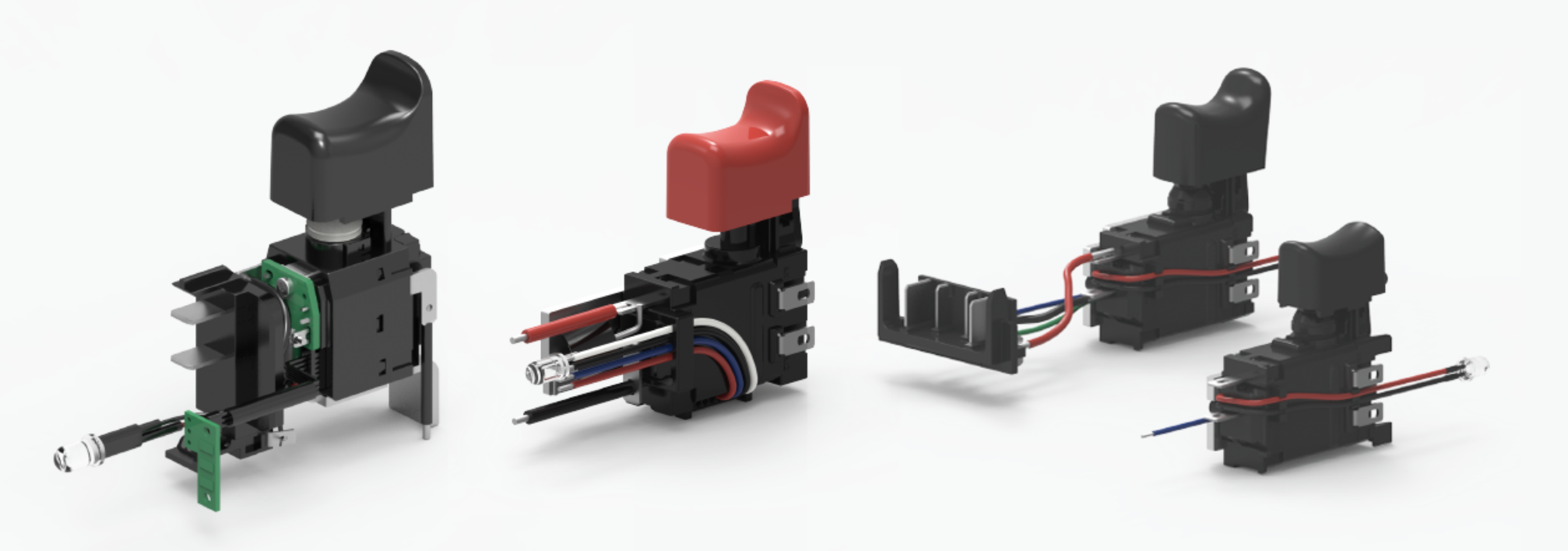

Building upon the understanding of the significance of power tool switches in electrical safety, it is essential to delve into the different types that are commonly used. These switches, often produced by a variety of power tool switch manufacturers, vary greatly in their design and function.

| Switch Type | Description |

|---|---|

| Toggle Switches | They are widely manufactured by power tool switch factories due to their simplicity and durability. |

| Push Button Switches | This type is frequently distributed by power tool switch vendors for its ease of use and quick response time. |

| Rocker Switches | Preferred by many users for its visible status, these are supplied extensively by power tool switch China suppliers. |

| Slide Switches | Known for their compact size, these switches are common products from different types of power tool switch manufacturers globally. |

Each type offers distinctive features tailored to various operational needs and safety requirements.

NEC Requirements for Power Tool Switch Installation

Section 4 explores the specific requirements and considerations set by the National Electrical Code (NEC) for power tool switch installation. This section aims to provide a comprehensive overview of relevant sections within the NEC that pertain directly to this field. In-depth analysis will be provided, elucidating particular directives and guidelines stipulated by the NEC, thereby fostering an understanding of how these regulations impact switch installations for power tools.

Regulations within the National Electrical Code crucially inform the procedures for power tool switch installation, with specific sections delineating requirements and restrictions. Specifically, Section 110 of the national electrical code outlines general rules for electrical installations. This section emphasizes that all electrical equipment should be installed in a safe and secure manner to minimize potential hazards.

Another relevant section is Article 430 which provides detailed guidelines on the installation of motors and their corresponding switches. These principles are particularly pertinent when dealing with power tool switch operations. Furthermore, Section 240 focuses on overcurrent protection, ensuring power tools do not exceed their designated current capacity.

These sections collectively underscore the importance of adhering to the national electrical code when installing a power tool switch, thereby promoting safety and efficiency in usage.

Specific requirements and considerations

Delving into the specifics, one must not lose sight of the forest for the trees when considering requirements and considerations pertinent to this subject. The National Electrical Code (NEC) outlines specific standards that a weup power tool switch manufacturer must consider during power tool switch installation.

- NEC’s impact on electrical equipment:

- NEC necessitates certain safety features in all electrical equipment, including power tools.

- It demands strict adherence to guidelines related to wiring and grounding techniques.

- Specific Requirements and Considerations:

- Power tool manufacturers are required by NEC to ensure switches can withstand the operational load.

- Special consideration should be given to areas with potentially explosive atmospheres where the use of non-sparking tools is mandated.

Adherence to these regulations ensures secure installations while also mitigating potential hazards associated with electricity.

Wiring Methods for Power Tool Switches

The ensuing discourse will encompass the suitable methods for wiring power tool switches, in accordance with the specifications set forth by the National Electrical Code (NEC). A critical focus will be placed on understanding the significance of adhering to proper techniques during this process, as it serves to minimize potential electrical hazards. The pertinence and implications of such precautionary measures within diverse contexts will thus form a central theme within this discourse.

Appropriate wiring methods as per NEC guidelines

Ensuring safety and functionality in power tool switch installation, National Electrical Code (NEC) guidelines specify appropriate wiring methods. The code emphasizes several factors that must be considered during the installation process to ensure adherence to NEC guidelines.

- Firstly, the type of power tool switch is crucial as different switches require different wiring methods.

- Secondly, the electrical capacity of the device must be taken into account as this impacts the thickness and type of wire used.

- Thirdly, environmental factors such as humidity, heat and dust also influence the wiring method selected.

- Lastly, safety considerations including grounding, insulation and protection against short circuits are essential elements of NEC compliant installations.

In sum, compliance with national electrical code not only ensures safe operation but also prolongs the lifespan of a power tool switch.

Importance of using proper wiring techniques to minimize electrical hazards

Moving away from the comprehensive exploration of appropriate wiring methods as mandated by the National Electrical Code (NEC), attention must now be directed towards understanding the significance of employing such techniques in power tool switch installation. The use of proper wiring techniques, as stipulated by the NEC, is pivotal in decreasing potential electrical hazards. Incorrect or haphazard installations could lead to malfunctions and pose significant risks such as fires or electrocutions. The National Electrical Code serves as a beacon guiding safe and efficient workmanship within this field. Its adherence ensures that power tool switches are installed effectively, thereby fostering a safer environment for users. In essence, it underlines the connection between suitable wiring techniques and minimization of electrical hazards during power tool switch installations.

Grounding and Bonding Requirements

Understanding grounding and bonding requirements for power tool switches is paramount in the realm of electrical safety. These regulations, outlined by national and international standards, are designed to ensure that all electrical equipment, including power tools, have a safe path to discharge electricity in case of a malfunction or fault. Adequate grounding serves as an essential protective measure against potential electric shocks resulting from stray currents, hence making it crucial for the prevention of workplace accidents or injuries.

Grounding and bonding requirements for power tool switches

National Electrical Code regulations mandate grounding and bonding for power tool switches to create an effective fault-current path, mitigating the risk of electrical shock or fire. This is crucial as it ensures that any potential excess electricity is safely redirected away from users during operation. Grounding involves connecting a conductive object (the power tool switch in this instance) to the earth, thereby creating a direct pathway for electrical energy discharge.

Conversely, bonding requirements necessitate a permanent joining of metallic parts to form an electrically conductive path. This aids in ensuring continuity and the capacity to carry current under malfunction scenarios. The National Electrical Code meticulously delineates these installation procedures, guaranteeing safety standards are adhered to when installing power tool switches, thus promoting user safety and equipment longevity.

The importance of proper grounding to prevent electrical shocks

Proper grounding techniques play a crucial role in preventing electrical shocks, thereby ensuring the safety and well-being of individuals handling such equipment. The ground wire is an essential component that acts as a safe path, diverting the current away from the user in case of an accidental electrical contact. This is especially important for power tool switches where the risk of electrical shock is high.

The National Electrical Code stipulates the use of equipment grounding conductors to establish this protective measure. Additionally, installation of a ground fault circuit interrupter (GFCI) adds another layer of protection by automatically shutting off power when accidental contact with electricity occurs, thus minimizing potential harm. Therefore, adherence to these codes not only ensures compliance but also promotes safety during operations involving power tools.

NEC Guidelines for Enclosures and Protection

The National Electrical Code (NEC) provides comprehensive guidelines on enclosures and protection for power tool switches, setting standards that ensure optimal safety in their usage. These guidelines prioritize the enhancement of safety by minimizing potential risks associated with accidental contacts and electrical mishaps during operation. A thorough understanding of these regulations serves to promote safer workplaces, reduce equipment damage, and enhance overall productivity.

EC guidelines regarding enclosures and protection for power tool switches

Remarkably, NEC guidelines stipulate that nearly 80% of power tool switch installations require an enclosure for protection, highlighting the substantial emphasis placed on safety in electrical work. The National Electrical Code provides explicit rules about enclosures and protection for power tool switches to prevent potential hazards.

- The NEC mandates that a power tool on-off switch must be housed within an enclosure to guard against accidental activation or deactivation.

- This provision significantly reduces the risk of unintended operation, thereby enhancing worker safety.

- These enclosures also shield the power tool switch from external damage, contributing to prolonged equipment lifespan.

In essence, these NEC guidelines underscore the importance of meticulous planning and adherence during power tool switch installation to maintain both user safety and equipment integrity.

How enclosures enhance safety and prevent accidental contact

Incorporating enclosures in the design of electrical equipment significantly escalates safety measures by acting as a robust barrier against accidental contact. These protective structures, aligned with National Electrical Code regulations, are essential elements in power tool switch installation. Specifically, they provide a physical layer of protection that mitigates risks linked to inadvertent interaction with live components, thereby decreasing possibilities of electrical shock or short circuit.

Safety is thus substantially enhanced through this approach which also factors in user behavior and environment dynamics. By limiting access to only qualified personnel for maintenance or adjustments and preventing unauthorized ingress of foreign objects or substances, enclosures serve a crucial function in ensuring compliance with NEC guidelines and promoting safe operation of power tools.

Compliance Testing and Inspection

Section 8 focuses on the critical role of compliance testing and inspection in ensuring adherence to National Electrical Code (NEC) standards for power tool switch installations. This section aims to provide an overview of common tests and inspections that are performed to guarantee safe power tool operation, preventing potential hazards related to improper electrical wiring or equipment failure. Through rigorous testing protocols and meticulous inspections, compliance with NEC standards can be verified, thus promoting safety and efficiency in the use of power tools.

Importance of compliance testing and inspection to ensure adherence to NEC standards

Ensuring adherence to the National Electrical Code (NEC) standards, compliance testing and inspection play a pivotal role in maintaining safety, enhancing efficiency, and promoting accountability in power tool switch installation. The stringent application of NEC standards during these processes ensures regulatory compliance and helps prevent potential hazards.

| Compliance Testing | Importance |

|---|---|

| Safety Assurance | Ensures that power tool switches are installed safely according to NEC standards. |

| Efficiency Improvement | Enhances operational efficiency by confirming all components function as expected. |

| Regulatory Adherence | Guarantees conformity with national electrical code requirements. |

Similarly,

| Inspection | Importance |

|---|---|

| Preventive Measure | Identifies potential issues before they escalate into major problems. |

| Quality Control | Affirms the quality of installation work is up to par with NEC standards. |

These steps validate the significance of adhering to NEC standards in power tool switch installations.

Common tests and inspections performed on power tool switch installations

Delving into the specifics, a variety of tests and inspections are routinely carried out to ascertain the reliability and efficacy of equipment interfaces, particularly in the context of power tool switch installations. Adherence to National Electrical Code (NEC) standards is checked rigorously.

- Dielectric Strength Tests: To ensure switches can withstand high-voltage electrical surges without failure.

- Continuity Checks: To ascertain seamless energy flow through power tool start switches.

- Insulation Resistance Inspections: For verifying adequate insulation levels as per NEC guidelines.

- Mechanical Endurance Testing: Assessing durability under prolonged use conditions.

These common tests and inspections not only validate compliance with the national electrical code but also build confidence in the safety measures adopted in power tool switch installation procedures thereby evoking an emotional response in audiences towards adherence to standardized practices.

Common Mistakes to Avoid

In the realm of power tool switch installation, a multitude of common errors emerge that may compromise the effectiveness and safety of the equipment. The subsequent section will elucidate these recurring mistakes and delineate potential repercussions that may ensue if not properly addressed or corrected. Moreover, this discourse aims to provide practical guidance to circumvent these pitfalls, thereby promoting not just efficiency but also ensuring adherence to safety protocols during the installation process.

Common mistakes made during power tool switch installation

Could it be that the frequent malfunctions of power tools are rooted in improper switch installation, a common mistake often overlooked during the assembly process? Indeed, adherence to the national electrical code can significantly mitigate such issues.

Common mistakes made during power tool switch installation not only compromise the functionality but also safety. This usually happens when replacing a power tool trigger switch or installing a power tool on-off safety switch.

| Mistake | Impact |

|---|---|

| Ignoring National Electrical Code | Can lead to dangerous installations and potential equipment malfunction |

| Incorrect wiring during replacement | May disrupt normal operation and affect safety |

| Overlooking on-off safety switches | Risks accidental activation causing injury |

| Bypassing grounding system | Increases chances of electrocution |

Avoiding these common pitfalls ensures safe and effective use of power tools.

Potential consequences of these mistakes and how to avoid them

Understanding the repercussions of these common errors and strategies to prevent them is crucial for ensuring optimized functionality and safety when using equipment. Improper power tool switch installation can have significant potential consequences, many of which are stipulated by the National Electrical Code (NEC). These may include:

- Electrical Safety Issues: Non-compliance with the national electrical code often results in issues such as short-circuiting or overheating, posing a risk to operators and surrounding infrastructure. This can be avoided by:

- Ensuring proper insulation of wires during installation.

- Regularly inspecting tools for signs of wear and tear.

- Operational Inefficiencies: Incorrect installations could lead to frequent equipment breakdowns, hampering productivity. To avoid mistakes, it’s advised to:

- Follow manufacturer’s guidelines for switch installation.

- Engage certified professionals for complex installations.

Benefits of Complying with NEC for Power Tool Switch Installation

Adherence to the National Electrical Code (NEC) guidelines for power tool switch installation offers a plethora of benefits. Primarily, it fosters improved safety by reducing potential electrical hazards, thus minimizing liability in case of accidents or equipment malfunctions. Furthermore, compliance with NEC provisions ensures enhanced efficiency and longevity of power tools, thereby promoting cost-effectiveness and productivity within operations.

Discuss the advantages of following NEC guidelines for power tool switch installation

Following the guidelines of the National Electrical Code (NEC) for power tool switch installation ensures optimal safety, preventing electrical accidents and promoting efficient operation. Adherence to NEC guidelines offers several advantages. Firstly, it facilitates correct power tool switch installation, reducing potential mishaps that could result from improper setup. Secondly, understanding the diverse power switches types as stipulated by NEC allows for more informed selection and application of these components in various operational settings. Furthermore, compliance with the national electrical code safeguards against regulatory penalties or legal issues that may arise from non-compliance. Lastly, adherence to NEC standards enhances the longevity and performance of power tools due to proper switch installation practices. In essence, following NEC guidelines is both a safe and wise approach to power tool switch installation.

Improved safety, reduced liability, and enhanced efficiency

Meticulous compliance to established guidelines significantly amplifies safety measures, diminishes potential liabilities, and bolsters operational efficiency in various settings. This holds true particularly for the installation of power tool switches under the purview of the National Electrical Code (NEC). The NEC’s stipulations aim primarily at improved safety through precise standards that minimize risks associated with electrical hazards. Such adherence also contributes to reduced liability for both manufacturers and users by ensuring that equipment meets or exceeds regulatory expectations. Furthermore, a focus on enhanced efficiency is evidenced in these regulations, as they offer clear guidance on best practices for power tool switch installation. Consequently, this results in minimal downtime from switch failures and facilitates seamless operations. Thus, following NEC guidelines aids in creating a safer and more efficient environment while mitigating potential legal repercussions.

Conclusion

In conclusion, the importance of understanding and adhering to the National Electrical Code (NEC) for power tool switch installation has been emphasized. It is crucial, from a safety perspective, as well as from a legal standpoint, to ensure compliance with these regulations. The priority should not only be on accomplishing tasks but also on maintaining safety standards and following national electrical guidelines meticulously.

The importance of understanding and complying with the NEC for power tool switch installation

Comprehension and adherence to the National Electrical Code (NEC) prove vital for power tool switch installation, not only ensuring safety standards but also contributing to the reliability and efficiency of these tools. The NEC plays a crucial role in:

- Setting guidelines: It provides essential instructions for the installation and maintenance of electrical equipment, including power tool switches.

- Enhancing safety: By complying with the NEC, potential electrical hazards can be mitigated, thereby protecting users from possible injuries.

- Ensuring functionality: Proper installation according to the national electrical code helps ensure that power tools operate effectively and reliably.

- Promoting standardization: The NEC fosters uniformity in practices across installations, facilitating consistency in performance and safety measures of all types of electrical equipment.

Therefore, understanding and complying with the NEC is indispensable for safe and effective power tool switch installation.

Prioritize safety and adhere to national electrical standards

Following the recapitulation of the significance of comprehending and complying with the National Electrical Code (NEC) for power tool switch installation, it is imperative to underscore the need for prioritizing safety. The NEC, as a comprehensive set of electrical standards developed by the National Fire Protection Association, lays out stringent guidelines designed to ensure safety during electrical installations including those of power tool switches. Ensuring strict adherence to these standards not only facilitates regulatory compliance but also significantly minimizes potential risks linked with electrical mishaps. Therefore, when conducting power tool switch installations, paramount emphasis should be placed on aligning practices with the NEC requirements. This commitment towards safe installations underscores an acknowledgment and respect for these established national electrical codes. It simultaneously promotes a culture of safety which is integral in any technical undertaking involving electricity.

Frequently Asked Questions (FAQs)

The ensuing discussion aims to address the frequently asked questions pertaining to the National Electrical Code (NEC), specifically its purpose and frequency of updates. Additionally, it seeks to elucidate any potential exemptions or exceptions within NEC regulations and the ramifications resulting from non-compliance. The conversation will also delve into the implications of incorrect power tool switch installation on tool performance, unveiling a comprehensive understanding of these critical aspects.

What is the purpose of the National Electrical Code?

Primarily, the purpose of the National Electrical Code is to provide a set standard for safe electrical installation practices across the nation. This code includes specific regulations pertaining to power tool switch installation. The code provides clear guidelines on how all components, including electrical wires and circuit breakers, should be installed and managed effectively. Emphasis is placed on ensuring overcurrent protection to prevent any potential risks or hazards related to electricity use. Following these guidelines ensures that power tools are safely connected and operate within specified parameters. In essence, the national electrical code aims not only at maintaining safety but also enhancing efficiency in power tool usage by dictating proper standards in switch installations and other associated practices.

How often does the NEC get updated?

In order to keep pace with the ever-evolving electrical industry and its technologies, updates to the NEC are made every three years. These revisions aim to enhance electrical safety in all areas of installation, including power tool switch installation.

The three-year cycle for NEC update ensures that the national electrical code remains current with advancements in technology and practices within the industry. This includes changes that may affect power tool switch installations, which are critical components in ensuring operator safety when using these devices. The regular review and revision process is crucial in maintaining a high standard of electrical safety across various applications.

Therefore, adherence to the most recent version of NEC is essential for professionals involved in power tool switch installation as it provides up-to-date guidelines on best practices and safety measures.

Are there any exemptions or exceptions to NEC regulations?

Despite stringent adherence to NEC regulations being paramount, certain nuances exist where exemptions or exceptions may be granted, akin to a riveting plot twist in an intricate novel, stirring emotions of surprise and relief among the audience. These exceptions primarily apply to installations that pre-date current codes. For power tool switch installation, the national electrical code may allow for existing switches to remain in use under specific conditions. This is often contingent upon the equipment maintaining safety standards despite not meeting modern requirements. Hence, while such exemptions provide some flexibility within regulations, they do not compromise on safety considerations inherent in NEC’s stipulations. It should be noted that these exemptions are relatively infrequent and must meet strict guidelines before approval, reinforcing the significant impact of NEC’s commitment to electrical safety.

What are the consequences of not following NEC guidelines?

Failure to adhere meticulously to the stipulations of NEC guidelines can usher in a plethora of repercussions, not merely limited to legal penalties but also encompassing potentially devastating safety hazards. The installation of power tool switches is one such area where these consequences become starkly evident. Neglect or ignorance towards the National Electrical Code may result in unsafe wiring conditions, which could lead to electrical malfunction, fire hazards, or even fatal accidents.

Moreover, noncompliance with these guidelines can attract hefty fines and potential litigation – a situation businesses would prefer avoiding. Thus, understanding and implementing the provisions set forth by the national electrical code is paramount for safe power tool switch installation. It not only ensures adherence to regulatory standards but also guarantees an environment conducive to worker safety and efficiency.

How can improper power tool switch installation impact tool performance?

Compromised integrity in the setup of control mechanisms for mechanical equipment can significantly hinder optimal performance, potentially leading to decreased productivity and increased maintenance costs. This is particularly true when it comes to power tool switch installation. Deviating from the national electrical code during this process can result in improper power tool switch installation, which directly impacts tool performance.

- Non-compliance with power tool rules could lead to inconsistent operational efficiency.

- Improper wiring might cause unexpected device shutdowns, hindering work progress.

- Inadequate insulation may contribute to overheating issues, reducing lifespan of the tools.

- Incorrectly installed switches may pose safety risks due to erratic operation or even electrical shock hazards.

- Overuse or misuse due to inadequate controls might lead to premature wear and tear of components.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd