A PID temperature controller maintains a desired temperature by continuously adjusting a heating or cooling element based on the difference between the measured temperature and the setpoint. It uses three control actions: Proportional, Integral, and Derivative, which work together to minimize temperature fluctuations and maintain a stable temperature.

- The temperature controller measures the current temperature using a sensor (e.g., thermocouple, RTD).

- It calculates the error, which is the difference between the measured temperature and the desired setpoint.

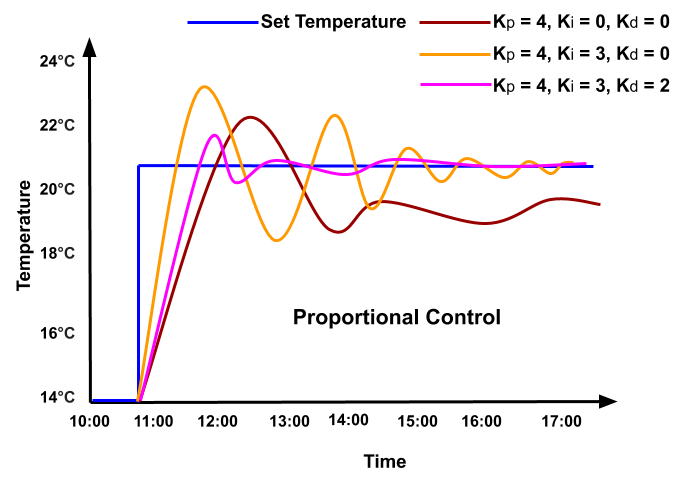

- Proportional (P):

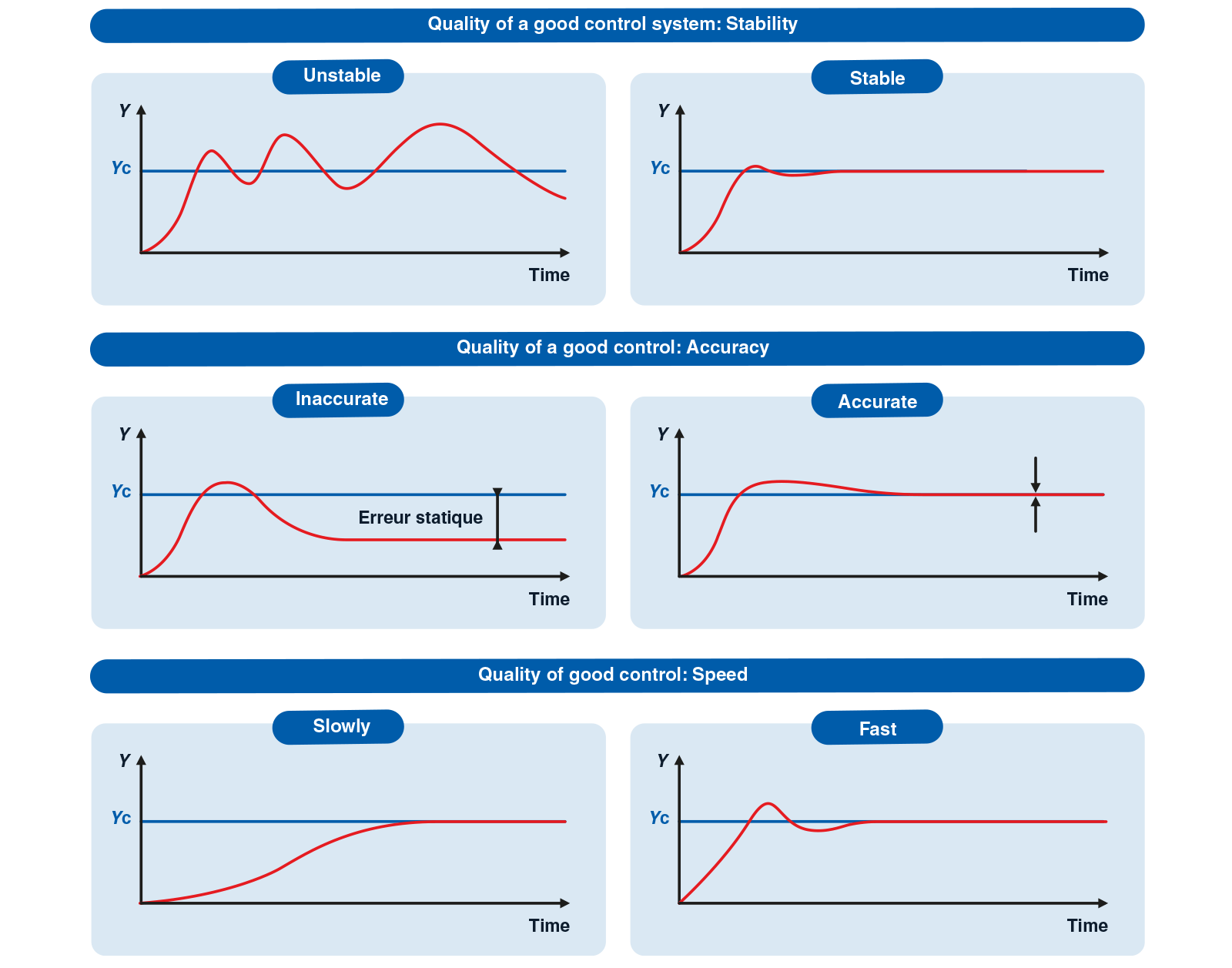

The controller applies an output proportional to the current error. A larger error results in a larger output. However, relying solely on proportional control often leaves a steady-state error (the temperature doesn’t exactly reach the setpoint).

- Integral (I):

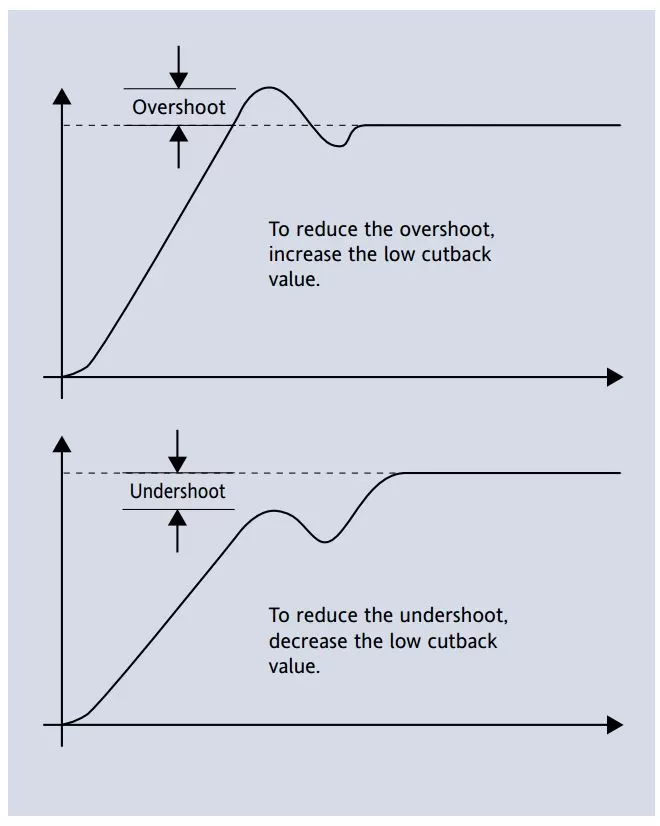

The integral action sums the error over time. This helps eliminate the steady-state error by continually adjusting the output until the error is zero. However, it can also cause overshoot (the temperature temporarily goes above the setpoint) if not tuned properly.

- Derivative (D):

The derivative action anticipates future temperature changes based on how quickly the error is changing. It helps stabilize the system by reducing overshoot and oscillations. The derivative component helps the controller react more quickly to changes in temperature.

- The PID controller combines the proportional, integral, and derivative terms to calculate a control signal. This signal is used to adjust the output to the heating or cooling device (e.g., a heater or a fan).

- The controller continuously monitors the temperature, recalculates the error, and adjusts the output accordingly to maintain the desired setpoint.