What is a 12V Rocker Switch?

A 12V rocker switch is an electrical switch designed specifically for 12-volt DC circuits that rocks back and forth when pressed, with one side of the switch raised while the other side is depressed. This seesaw-like action either opens or closes the electrical circuit, controlling the flow of power to various devices and equipment. These switches are widely recognized for their reliability, ease of use, and versatility across numerous applications.

12V rocker switches are essential components in various electronic systems, providing intuitive control and dependable performance in low-voltage applications. They are easily identifiable by their distinctive rocking mechanism and are often labeled with “ON” and “OFF” markings for clear operation status. Many models feature built-in LED indicators that illuminate when the circuit is active, providing visual confirmation of the switch position.

How Does a 12V Rocker Switch Work?

The operation of a rocker switch is straightforward yet highly effective. When pressed, the rocker mechanism toggles between positions, making or breaking electrical connections inside the switch housing. This simple mechanical action controls the flow of electricity through the circuit.

Structure and Operation

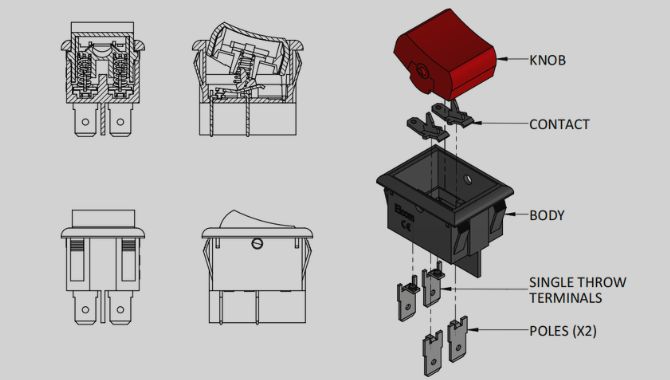

The internal structure of a 12V rocker switch typically consists of:

- A durable plastic or nylon housing that protects the internal components

- Metal contacts that connect or disconnect when the switch is operated

- Terminal points for connecting wires to the circuit

- A spring-loaded rocker mechanism that maintains position until changed

- Optional LED indicator with current-limiting resistor (in illuminated models)

When the switch is pressed, the rocker pivots around a central point, causing the internal contacts to either connect (ON position) or disconnect (OFF position). This requires minimal force and provides tactile feedback to confirm the action has been completed. The design ensures reliable operation even in environments with vibration or frequent use.

Types of 12V Rocker Switches

WEUP offers a comprehensive range of 12V rocker switches to meet diverse application requirements. Understanding the different types available helps in selecting the most appropriate switch for your specific needs.

Function-Based Classification

Single-Pole Single-Throw (SPST)

The most basic and commonly used type, SPST 12V rocker switches control a single circuit with simple ON/OFF functionality. They have two terminals and are ideal for basic power switching applications like turning lights or accessories on and off.

.jpg)

Single-Pole Double-Throw (SPDT)

SPDT 12V rocker switches have three terminals and can connect one circuit to either of two others. These switches are perfect for applications requiring selection between two different options, such as switching between two power sources or controlling reversible motors.

Double-Pole Single-Throw (DPST)

DPST switches feature four terminals that control two separate circuits simultaneously. They function like two SPST switches operated by a single rocker, making them ideal for applications where two circuits need to be powered on or off together.

Double-Pole Double-Throw (DPDT)

The most versatile option, DPDT 12V rocker switches have six terminals and can switch two separate circuits between two different states. They’re commonly used in complex applications like reversing motor direction or switching between multiple power sources.

Illumination Options

Non-Illuminated Switches

Basic 12V rocker switches without lighting elements, offering reliable operation at a lower cost for applications where visual indication isn’t necessary.

LED Illuminated Switches

These 12V rocker switches feature built-in LED indicators that light up when the switch is in the ON position, providing clear visual confirmation of the switch status. WEUP offers various LED colors including red, green, blue, yellow, and white to match your application requirements or color-coding needs.

Special Features

Waterproof Rocker Switches

Designed with sealed housings and rubber gaskets, waterproof 12V rocker switches offer protection against moisture, dust, and other contaminants. These switches are rated with IP65 or IP67 protection, making them ideal for marine, outdoor, and harsh environment applications.

Momentary Rocker Switches

Unlike standard latching switches that maintain their position, momentary 12V rocker switches return to their default position when released. They’re perfect for temporary activation applications like horn buttons or temporary lighting.

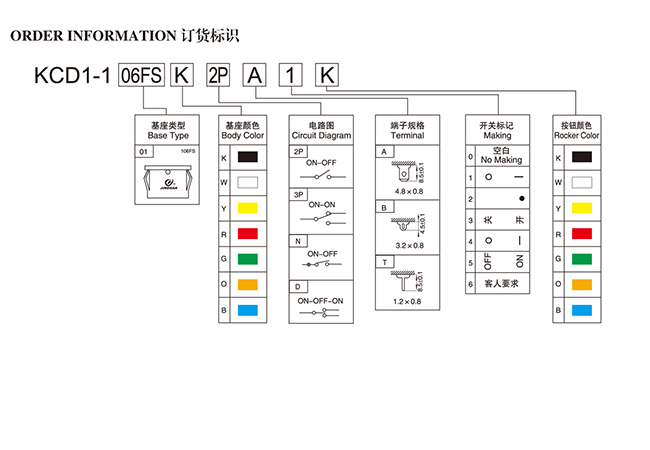

Product Parameters

Parameter | Specification |

|---|---|

Product Item | WEUP KCD1 |

Rated Voltage | 12V DC |

Current Rating | 10A, 15A, 20A (model dependent) |

Contact Configuration | SPST, SPDT, DPST, DPDT |

Contact Way | Solder pin / Quick connect terminals |

Install Method | Panel mount / Snap-in |

Illumination | LED / Non-illuminated |

LED Color Options | Red, Green, Blue, Yellow, White, Black |

Shell Material | High-quality ABS plastic |

Base Material | PA66 nylon (flame-retardant) |

Terminal Material | Brass / Copper |

Waterproof Rating | IP65 / IP67 (waterproof models) |

Operating Temperature | -25°C to +85°C |

Life Cycle | 10,000+ operations |

Certifications | CE, RoHS, UL (as applicable) |

Applications of 12V Rocker Switches

12V rocker switches are versatile components used across numerous industries and applications. Their reliability, ease of use, and durability make them ideal for controlling various electrical systems operating on 12V DC power.

Automotive Applications

In automotive systems, 12V rocker switches are extensively used for:

- Controlling auxiliary lighting systems

- Operating power windows and door locks

- Managing entertainment systems

- Activating heating and cooling systems

- Powering accessories like USB chargers and 12V outlets

Marine Applications

Marine environments demand reliable and waterproof components, making specialized 12V rocker switches essential for:

- Navigation and anchor lighting control

- Bilge pump operation

- Marine electronics power management

- Windlass and winch control panels

- Cabin lighting and accessory power

Recreational Vehicles (RVs)

RVs and campers utilize 12V rocker switches for numerous systems:

- Interior and exterior lighting

- Water pump control

- Awning and slide-out operation

- Battery management

- Climate control systems

Industrial Equipment

In industrial settings, 12V rocker switches provide reliable control for:

- Control panels for machinery

- Safety systems

- Conveyor and material handling equipment

- Monitoring and testing equipment

- Portable power tools and equipment

Home and Commercial Applications

12V rocker switches are also found in various home and commercial applications:

- Low-voltage lighting systems

- Security systems

- HVAC controls

- Small appliances

- DIY electronics projects

How to Wire a 12V Rocker Switch

Proper wiring of your 12V rocker switch ensures safe and reliable operation. Follow these guidelines for different switch configurations:

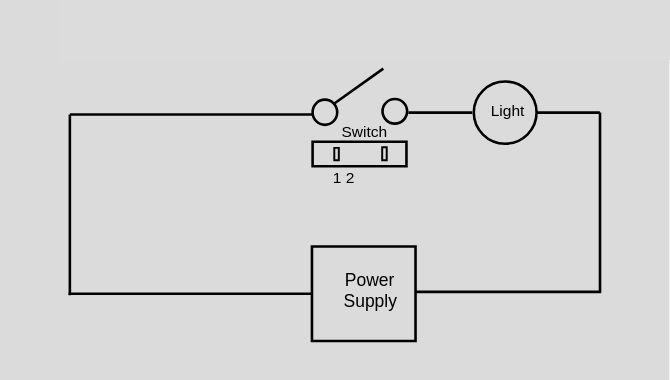

Basic ON/OFF Switch Wiring (SPST)

- Identify the two terminals on your SPST 12V rocker switch

- Connect the positive wire from the power source to one terminal

- Connect the other terminal to the positive wire of your device/load

- Ensure the negative/ground wire connects directly from the power source to the device

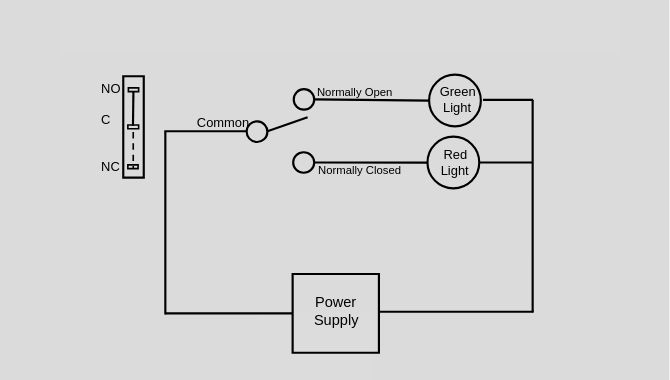

Three-Terminal Switch Wiring (SPDT)

- Locate the three terminals on your SPDT switch (common, normally open, normally closed)

- Connect the power source to the common terminal

- Connect one device to the normally open terminal

- Connect a second device to the normally closed terminal (if needed)

- This configuration allows switching power between two different devices

Illuminated Switch Wiring

- Identify all terminals on your illuminated 12V rocker switch

- Connect the power terminals as described above based on switch type

- For switches with separate illumination terminals, connect the positive illumination terminal to a power source

- Connect the negative illumination terminal to ground

- Some illuminated switches may have built-in connections that automatically power the LED when the switch is on

![Okay, wiring a 3-prong 12V illuminated rocker switch is a common task. These switches typically have: Power In (Supply/Line): Where 12V+ from your battery/power source connects. Load Out (Accessory): Where 12V+ goes to the device you want to control (light, fan, etc.). Ground (Negative): For the switch's internal LED illuminator. Common Pin Identification (Always verify if possible!): Brass/Gold Pin: Often the Ground terminal. Silver Pins (x2): One is Power In, the other is Load Out. The middle silver pin is frequently the Power In. The silver pin furthest from the Ground pin (or closest to where the "ON" position rocks down) is often the Load Out. Here's the typical wiring diagram: +-----------------------+ | 12V Power Source | | (Battery / Power Supply)| +----------+------------+ | (+) | [FUSE]](https://www.cweup.com/wp-content/uploads/2025/05/How-to-wire-a-3-prong-12v-Illuminated-rocker-switch.jpg)

How to Choose the Right 12V Rocker Switch

Selecting the appropriate 12V rocker switch for your application involves considering several important factors:

Current and Voltage Requirements

- Ensure the switch is rated for 12V DC operation

- Select a switch with a current rating that exceeds your circuit’s maximum current draw

- For high-current applications, choose heavy-duty models rated for 15A or 20A

Environmental Considerations

- For outdoor or marine applications, select waterproof 12V rocker switches with appropriate IP ratings

- Consider temperature extremes in your application environment

- For dusty environments, choose sealed switches with dust protection

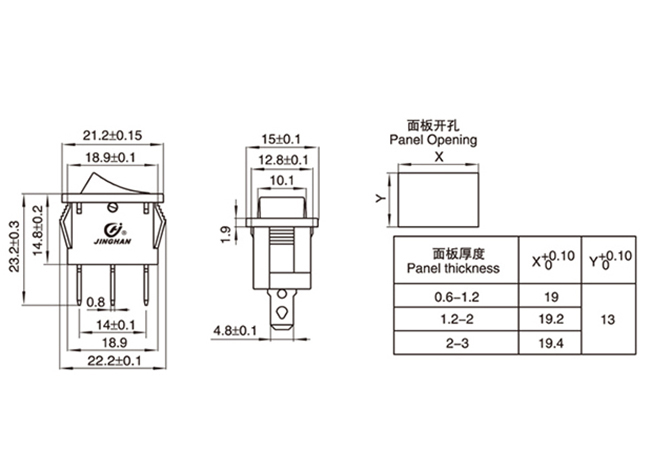

Physical Dimensions and Mounting

- Measure the available space for switch installation

- Determine the panel thickness and required mounting hole size

- Consider the depth clearance behind the panel

- Choose between snap-in or threaded mounting options based on your installation requirements

Illumination Needs

- Decide if illumination is necessary for your application

- Select appropriate LED color for visibility and indication purposes

- Consider whether you need the LED to indicate when the switch is ON or OFF

Aesthetic Considerations

- Choose switch color and style that matches your control panel design

- Consider labeled switches for clear function identification

- Evaluate the ergonomics and ease of operation

Reliability Requirements

- For critical applications, select switches with higher cycle ratings

- Consider switches with gold-plated contacts for low-current applications

- Evaluate the manufacturer’s reputation and warranty offerings

WEUP 12V rocker switches are designed to meet the highest standards of quality and reliability, ensuring optimal performance across all these considerations.

WEUP 12V Rocker Switches: Superior Quality and Value

WEUP is committed to providing exceptional 12V rocker switches that exceed industry standards and customer expectations. Our switches are engineered with a focus on quality, durability, and customer satisfaction.

Uncompromising Quality

WEUP 12V rocker switches are manufactured using premium materials and undergo rigorous testing to ensure consistent performance and reliability. Each switch is inspected for proper operation, ensuring that only the highest quality products reach our customers.

Long-Lasting Durability

Built to withstand the test of time, WEUP switches are designed for extended service life even in challenging environments. Our switches feature robust construction with high-grade plastics and reliable internal components that maintain consistent performance through thousands of operations.

User-Friendly Operation

WEUP prioritizes ergonomic design in all our 12V rocker switches, ensuring smooth and effortless control. The tactile feedback provides clear confirmation of switch activation, while optional illumination enhances visibility in low-light conditions.

Versatile Compatibility

Our 12V rocker switches are compatible with various electrical systems and can be integrated into diverse applications. Whether for automotive, marine, industrial, or recreational use, WEUP switches provide reliable performance across the board.

Safety First

All WEUP 12V rocker switches incorporate built-in protection against electrical hazards. Our switches comply with international safety standards and are designed to provide peace of mind during operation.

Troubleshooting Common Issues

Even high-quality 12V rocker switches may occasionally experience issues. Here are solutions to common problems:

Switch Doesn’t Illuminate

- Verify power is reaching the switch

- Check for proper wiring of illumination terminals

- Ensure the LED is not damaged

- Confirm the circuit has proper grounding

Intermittent Operation

- Check for loose wire connections

- Inspect for corrosion on terminals

- Verify the switch is rated for your application’s current

- Ensure the switch is properly mounted and not moving in its housing

Switch Feels Stuck or Stiff

- Check for physical obstructions around the rocker

- Ensure the mounting hole is properly sized

- Verify the switch is not damaged internally

- For new switches, note that some initial stiffness is normal and will improve with use

Overheating

- Immediately disconnect power

- Verify the switch is properly rated for your application’s current

- Check for loose connections causing resistance

- Ensure proper ventilation around the switch

Safety Considerations

When working with 12V rocker switches, always follow these safety guidelines:

- Disconnect power sources before installation or maintenance

- Use appropriate wire gauge for your current requirements

- Ensure all connections are secure and properly insulated

- Install fuses or circuit breakers to protect against overcurrent

- Follow manufacturer’s specifications and recommendations

- Use waterproof switches for wet environments

- Regularly inspect switches and wiring for signs of wear or damage

Conclusion

12V rocker switches are essential components in numerous electrical systems, providing reliable control and intuitive operation. WEUP offers a comprehensive range of high-quality switches designed to meet diverse application requirements while ensuring durability, safety, and ease of use.

Whether you need switches for automotive, marine, industrial, or recreational applications, WEUP has the perfect solution to meet your needs. Our commitment to quality and customer satisfaction ensures that you receive products that perform reliably for years to come.

For more information about our 12V rocker switch offerings or to request a free sample, please contact our team. We’re dedicated to helping you find the ideal switching solution for your specific requirements.

Contact Information

Email: [email protected] Phone: +86-13285879777

Request a Free Sample Today!