Push button switches are life-saving interfaces in emergency systems, offering rapid, reliable activation when seconds count. Their design and functionality directly impact safety outcomes across medical, firefighting, and public security applications.

🚨 Why Push Button Switches Are Essential

1. Immediate Response Activation

- One-Press Activation: Simplifies operation under stress (e.g., cardiac defibrillators, fire alarms).

- Tamper-Resistant Designs: Prevent accidental triggering in high-stakes environments.

2. Fail-Safe Reliability

- Sealed & IP-Rated Switches: Resist water, dust, and chemicals (e.g., IP67 for fire trucks, ambulances).

- Redundant Circuitry: Backup contacts ensure function even with partial failure.

3. Universal Compliance

- Meets NFPA, IEC, and UL Standards: Critical for emergency equipment certification.

⚡ Key Applications in Emergency Services

| Application | Switch Type | Purpose |

|---|---|---|

| Hospital Crash Carts | Illuminated Mushroom (Emergency Stop) | Instant power cutoff for patient safety |

| Fire Alarm Pull Stations | Momentary Push-to-Break | Triggers building evacuation alerts |

| Ambulance Defibrillators | Tactile Medical-Grade | Delivers shocks with minimal delay |

| Police Vehicle Lights/Sirens | Latching Sealed Switch | Ensures sustained activation during pursuits |

| Industrial Emergency Shutdown (ESD) | Dual-NC Contacts | Halts machinery to prevent injuries |

🔧 Design Features for Emergency Use

- Color-Coding: Red (stop), Green (start), Yellow (caution) per ISO 3864.

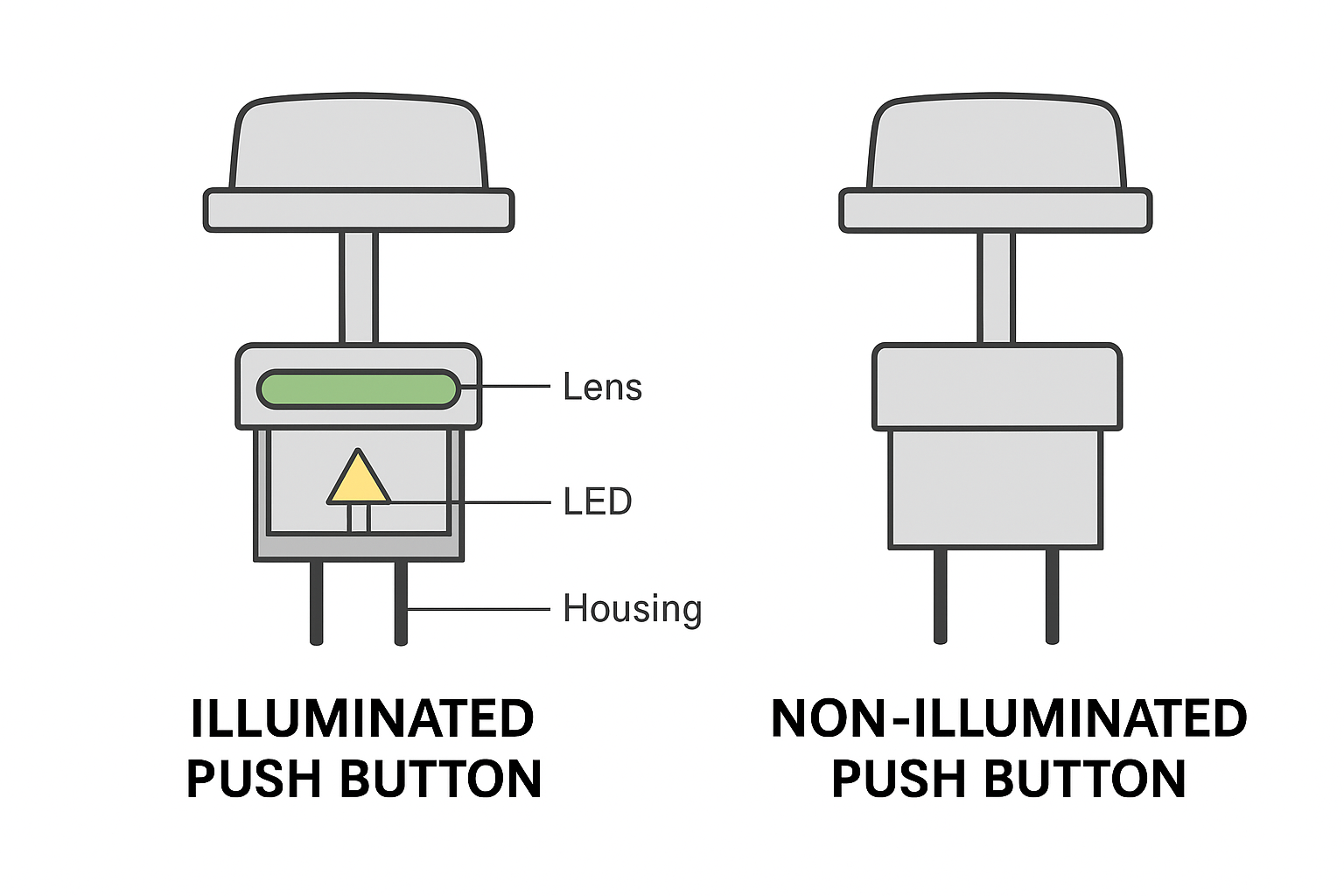

- High-Visibility Actuators: Glow-in-the-dark or LED-backlit buttons for low-light conditions.

- Anti-Vandal Construction: Metal housings resist blunt force (e.g., 16mm metal push buttons in prisons).

⚠ Risks of Non-Compliant Switches

- Slow Response Times: Cheap switches may stick or lag during crises.

- Corrosion Failures: Non-hermetic seals lead to malfunctions in humid/outdoor settings (e.g., marine emergencies).

- Electrical Noise: Poor EMI shielding can disrupt sensitive equipment (e.g., hospital ECG machines).

✅ Best Practices for Emergency System Integrators

- Prioritize Tactile Feedback: Audible “click” and haptic response confirm activation under stress.

- Test Under Simulated Conditions: Validate switches with vibration, temperature, and spill tests.

- Document Maintenance Logs: Replace switches per manufacturer’s lifespan recommendations (e.g., 50,000+ cycles for high-use panels).

🛠 Real-World Example: Defibrillator Switch Failure

A 2018 FDA recall involved AEDs (Automated External Defibrillators) with faulty membrane switches that delayed shock delivery. Post-recall models adopted tactile metal buttons with moisture-resistant seals.

Lesson: Switches in emergency devices must exceed general-use durability standards.

📢 Industry Outlook

- Voice-Activated & Gesture Controls are emerging, but physical push buttons remain critical for unconditional reliability.

- IoT Integration: Smart switches now transmit diagnostics (e.g., “Alarm Button #3 Needs Service”).

Need help selecting EMT-grade switches? Share your operating environment for tailored recommendations! 🚑🔌