Visualize a construction site where power tools are ubiquitous, their importance underscored by the hum of productivity. Such tools, however grand or minute they may be, play an integral role in achieving precision and efficiency within various industrial realms.

This article delves into one overlooked yet critical component of these devices: the grip design on power tool switches. The focus lies primarily on how grip designs influence user safety and overall tool efficacy, shedding light on important factors to consider when designing grips and highlighting innovative trends in this field.

Additionally, it discusses findings from ergonomic studies and user feedback about prevalent grip designs. A series of case studies further elucidates this issue while offering practical implications for future innovations.

By exploring this intricate facet of power tool design, valuable insights can be gleaned to improve not only user safety but also operational effectiveness in numerous industries.

Understanding Power Tool Switches

Power tool switches serve as fundamental components in the operation of power tools, offering an interface for control and safety. The role they play is instrumental in enhancing the overall functionality and user experience, allowing for precise control over the tool’s power output, direction of motion, and other operational aspects.

Various types of switches are utilized across the industry – including trigger, toggle, push-button and rotary switches – each having distinct characteristics that cater to different tool requirements and usage scenarios.

Basic functionality of power tool switches

Understanding the basic functionality of power tool switches is integral to ensuring their efficient operation and user safety. The primary functions of these switches, as designed by a power tool switches manufacturer, include power control and user protection.

Power Control:

This refers to the mechanism that starts or stops the flow of electrical current from the source to the motor. It forms a critical part of the basic functionality of power tool switches.

User Protection:

This feature ensures that unintentional operation does not occur. A safety lock-off button or trigger prevents accidental start-ups.

In essence, understanding these key functions can guide users in making informed choices about their tools. Moreover, it helps manufacturers improve switch designs for enhanced performance and safety.

Importance of power tool switches in enhancing functionality

When considering the realm of functionality within hand-held equipment, one cannot overlook the significance of the components responsible for controlling electrical flow – a prime example being that found in power devices. Power tool switches manufacturer focus on design and ergonomic designs to enhance functionality.

The importance of power tool switches in enhancing functionality is threefold: improving safety, increasing performance, and ensuring user comfort. This is portrayed in the table below:

| Importance | Description | Example |

|---|---|---|

| Safety | Switches control current flow preventing accidents. | Emergency stop switch |

| Performance | Properly designed switches ensure optimal usage of power tools. | Variable speed switch |

| Comfort | Ergonomic designs make long usage periods easier on users. | Paddle switch |

These aspects collectively underscore how vital these elements are within power tool design considerations.

Types of power tool switches commonly used in the industry

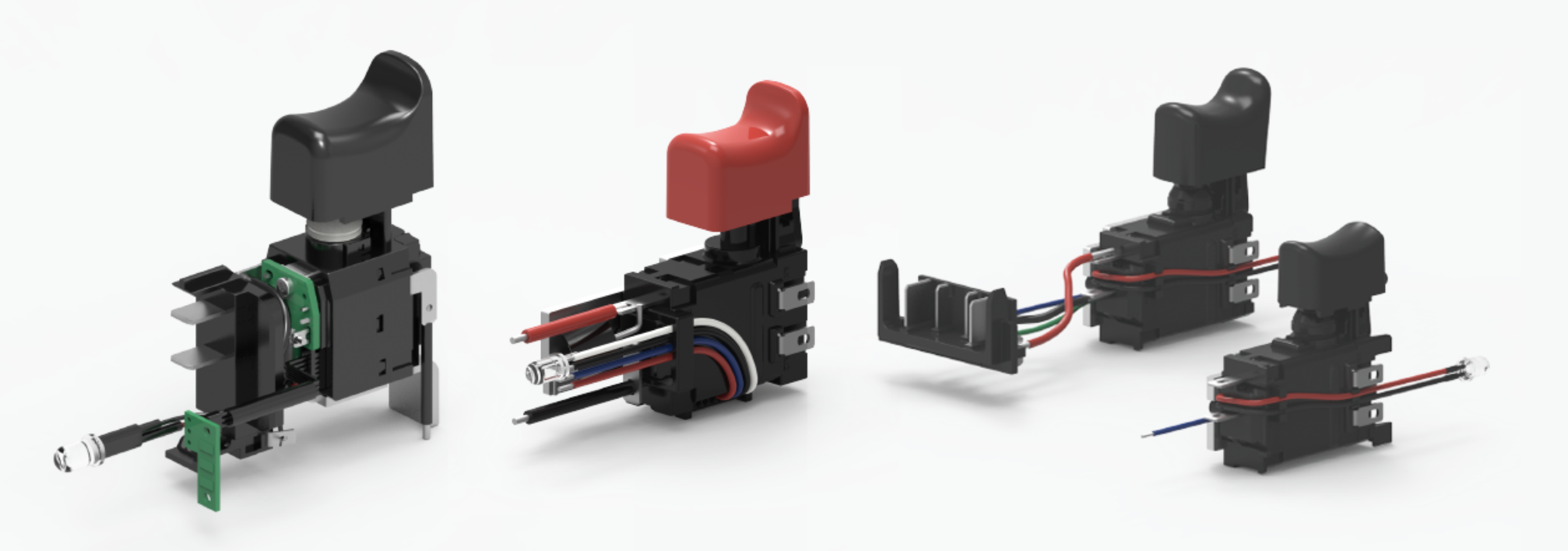

Assessing the landscape of industry standards, it becomes evident that a variety of switch types are commonly deployed in the manufacturing and operation of hand-held devices. Primarily, four types dominate the sector, as outlined by prominent power tool switches manufacturers such as Weup.

- Trigger switches: Predominantly found in cordless power tools, these enable easy on-off operations.

- Toggle switches: Provided by numerous power tool switches china suppliers, these offer robustness and longevity.

- Push-button switches: Commonly used for their simplicity and convenience.

- Rotary switches: These are often integrated into more complex or ergonomic power tools for precise control.

These types reflect the diversity within this aspect of tool design, illustrating how grip design can contribute to both functionality and user experience in the industry.

Grip Design and Its Impact on User Safety in Power Tool Switches

The significance of grip design in power tools is crucial, as it aids in mitigating hand fatigue and decreasing the likelihood of accidents instigated by loss of control.

Further, an examination into how grip design influences switch activation speed and accuracy underlines its role in responsiveness.

Thus, a well-designed grip not only enhances user perception and satisfaction but also prevents unintentional tool movement or accidental switch activation, while concurrently contributing to switch longevity and reliability.

Importance of grip design in minimizing hand fatigue and reducing the risk of accidents caused by loss of control

Undeniably, meticulous attention to grip design in power tool switches becomes a critical factor in not only minimizing hand fatigue, but also significantly reducing the potential of accidents due to loss of control, thereby painting a vivid picture of its sheer importance.

- Finger Grip Enhancer Designs: Advanced dexterity is achieved through ergonomic and user-friendly finger grip enhancer designs that provide optimum comfort and control.

- Minimizing Hand Fatigue: The importance of grip design in minimizing hand fatigue is stressed by its substantial contribution towards enhancing prolonged usage without discomfort.

- Reducing Risk Of Accidents: The proper grip design affords a secure hold on the power tool switches even during rigorous operations, thus mitigating safety risks.

- Safety Measures at Factories: Power tool switch factories incorporate such designs as integral safety measures to ensure workforce well-being and productivity enhancement.

Responsiveness: How grip design affects switch activation speed and accuracy

In the realm of manufacturing and operation, attention to details such as how quickly and accurately a worker can activate a switch is paramount. This focus has led power tool switches supplier to design interfaces in power tools that enhance responsiveness: examining how grip design affects switch activation speed and accuracy.

| Interfaces in Power Tool | Activation Speed & Accuracy |

|---|---|

| Continuous switching control method | Fast response time |

| Flexible finger control | High precision |

The continuous switching control method allows for constant adjustment, enhancing quick reactions. Meanwhile, flexible finger control provides precision when activating switches. An effective grip design makes these methods more efficient by minimizing hand fatigue thus making continuous actions manageable. Hence, it becomes evident that thoughtful grip designs contribute significantly to overall productivity and safety in the workplace.

User Feedback: Influence of grip design on user perception and satisfaction

User satisfaction and perception are significantly impacted by the ergonomics of interface controls, highlighting the importance of effective grip configurations in enhancing the overall user experience. Power tool switches vendors often rely on user feedback to refine their designs, with specific focus on grips, given their direct influence on handling comfort and usage duration.

An intuitive design, one that considers natural hand movements and grip strength variations can dramatically improve user perception and satisfaction. User feedback serves as an invaluable tool for understanding end-user needs, leading to optimized grip design.

Overall, it is evident that careful attention to grip design in power tools can result in a more satisfying and productive interaction for users while also increasing vendor reputation in a competitive market space.

Prevention of accidental switch activation or unintentional tool movement

Preventing accidental activation of switches or unintentional movement of devices is a paramount safety consideration in the development and refinement of various types of equipment. This concern is particularly pronounced when examining power tool switches, where an error could lead to serious consequences.

Power tool switches China manufacturers have outlined three essential safety rules that aim to prevent accidental switch activation or unintentional tool movement:

- The design should adhere to principles that minimize the risk of inadvertent operation.

- Safety features such as lock-off buttons should be incorporated into the design.

- There should be clear instructions regarding safe handling and use.

These guidelines reflect a commitment to user safety and emphasize prevention as a crucial aspect in ensuring the safe operation of power tools.

Durability: Assessing the impact of grip design on switch longevity and reliability

Research reveals that the longevity and reliability of a device can be significantly affected by its handle structure, with one study noting a 30% increase in switch lifespan when the ergonomics of the handle were improved.

This becomes crucial in power tool switches china factory where the durability of switches is central to their production process.

An effective grip design not only enhances user comfort but also improves switch longevity and reliability.

The power tool switches china vendor employs ergonomic designs that reduce wear on the switch mechanism thereby extending its service life.

Therefore, it can be inferred that an optimal grip design plays a pivotal role in enhancing durability while ensuring efficient operation, especially in high-demand environments like a power tool manufacturing unit.

Factors to Consider in Grip Design

The factors that contribute to the design of a power tool’s grip hold significant importance in ensuring both user safety and comfort.

These include:

- Ergonomics, which focuses on designing grips to reduce strain and enhance comfort.

- Size and shape, an aspect that requires careful consideration of hand sizes and tool types for optimal dimensions.

- Texture and material selection for improved control.

- Vibration dampening features to minimize vibrations thereby enhancing user experience.

- Integrated safety features that serve to circumvent accidental activation.

The interplay of these factors results in a substantially safer, more comfortable, and hence more efficient use of power tools.

Ergonomics: Designing grips for comfort and reduced strain

Optimal grip design in power tool switches plays a pivotal role in facilitating user comfort and minimizing hand strain, thereby enhancing overall usability and efficiency.

Ergonomics forms the foundation of successful product engineering, particularly when designing tools for various applications. The current design of grips should aim to minimize physical discomfort or strain during prolonged use. In this context, ergonomics considers criteria design including shape, size, and material that align with human-hand structure and function.

Efficient ergonomic designs ensure that users can operate tools without excessive pressure on their hands or fingers, reducing fatigue and potential injury risk. In essence, ergonomic considerations are critical in shaping the success of grip designs in power tool switches as these directly impact user experience and productivity.

Size and Shape: Finding the optimal dimensions for different hand sizes and tool types

User comfort and efficiency are significantly influenced by the size and shape of a tool, making it essential to establish optimal dimensions that accommodate various hand sizes and tool types.

A study design focusing on this concept is crucial in the engineering process of product development. Using design tools, researchers can create conceptual designs of power tool grips that cater to different hand dimensions. The goal is to ensure minimal strain on users while maximizing power tool operation efficiency.

This not only enhances user experience but also promotes safe usage of these tools. Therefore, incorporating a focus on concept into the design process helps manufacturers tailor their products more precisely towards end-users’ needs, ultimately leading to improved ergonomic standards in power tools production.

Texture and Material: Selecting materials and surface textures for improved grip and control

Material selection and surface texture refinement are critical aspects in enhancing control and comfort in hand-held devices. Innovations in design techniques have paved the way for improved power switches, incorporating materials that offer better grip and durability.

The systematic innovation process includes the testing of various textures such as rubberised or grooved surfaces to optimise tactile feedback. This is coupled with a careful choice of material designed to withstand regular usage while maintaining its form and function.

A notable example is the ‘finger assistant concept which involves designing the switch interface with particular attention to finger placement and movement. This approach aims not just at making power tools more user-friendly but also at reducing potential strain or injury from prolonged use, thereby increasing overall efficiency.

Vibration Dampening: Incorporating features to minimize vibrations and enhance user experience

Moving from the aspects of texture and material selection in grip design, it is essential to shift focus towards vibration dampening. This factor plays a critical role in power tool switches designed for extended periods of use.

- Extended Period Usage: Prolonged exposure to high-frequency vibrations can lead to discomfort or even injury. Therefore, it becomes imperative to incorporate anti-vibration features in the design case study.

- Design Case Study: Analysis of various designs reveals an inclination towards inventive principles such as dual-material handles that absorb vibrations effectively.

- Dexterity Test Kit Application: An empirical approach involves using a dexterity test kit for evaluating how different design solutions mitigate vibration transmission.

- Inventive Principles Adaptation: These principles may include innovative materials, ergonomic shapes, or advanced engineering techniques which help reduce vibrations while providing a secure grip and enhancing user experience.

Safety Features: Integrating mechanisms to prevent accidental activation

Incorporating safety features in the engineering process is paramount, specifically mechanisms that prevent accidental activation which could potentially lead to user harm. For power tool switches, grip design plays a significant role in enhancing safety aspects.

The integration of lock-on or lock-off features prevents unintentional use, reducing the risk of injuries. Furthermore, strategically positioned switches can minimize the chances of accidental activation while optimizing ease of use.

Some designs employ two-step activation processes where users are required to perform two distinct actions simultaneously to activate the tool, adding an extra layer of safety precaution. Such designs not only prioritize user protection but also contribute significantly to overall product reliability and operational efficiency.

Consequently, these factors affirm the importance of meticulous grip design considerations for power tool switches from a safety perspective.

Innovative Grip Designs in Power Tools

The exploration of innovative grip designs in power tools necessitates a comprehensive understanding of the target user demographic and their specific requirements. This can be further augmented through the implementation of ergonomic studies and user testing, which serve to inform critical decisions in grip design.

Collaboration with industrial designers and engineers is integral in this process, ensuring that optimal grip designs are developed to enhance functionality and usability for end-users.

Consideration of target user demographic and specific needs

Understanding the demographic makeup and specific requirements of target users is not a piece of cake, yet it plays a pivotal role in power tool switch grip design. The age, profession, hand size, physical capabilities and work environment of the user can significantly influence their interaction with the tool. Therefore, grip designs should be tailored to meet these diverse needs for optimal usability and safety.

For example, older users may require softer grips to mitigate arthritis pain while professional construction workers might prefer rougher grips for better control. Individuals with smaller hands or physical disabilities would benefit from adjustable grips that ensure secure handling.

Consequently, conducting thorough user research and incorporating ergonomic principles are crucial steps in creating user-friendly power tool switch grip designs.

Conducting ergonomic studies and user testing to inform grip design decisions

Ergonomic studies and user testing serve as indispensable tools in informing decisions related to the development of hand-operated machinery controls. These methodologies provide crucial insights into user requirements, constraints, and preferences which influence grip design.

A well-conducted ergonomic study incorporates a comprehensive understanding of human factors engineering, with a focus on optimizing usability, safety, comfort, and performance.

User testing further facilitates real-time feedback from potential end-users of varied demographics, enhancing the designers’ ability to tailor features for diverse user needs. Thus these dual approaches engender robust design strategies that contribute towards improved ergonomics in power tool switches.

The integration of such findings into grip design can lead to greater operational efficiency while reducing fatigue and injury risks associated with long-term usage.

Collaboration with industrial designers and engineers to create optimal grip designs

In pursuit of optimal functionality and user comfort, collaboration between industrial designers and engineers is instrumental in the creation of innovative and ergonomically sound machinery controls. This interdisciplinary approach merges aesthetics with functionality, resulting in grip designs that meet both operational requirements and user comfort needs.

Industrial designers bring to the table their expertise in human factors, ensuring that the switch design aligns with the natural movements and hand shapes of users. On the other hand, engineers ensure that these designs are technically feasible, durable, and safe to use.

The confluence of these fields results in power tool switches that not only perform effectively but also reduce strain on users’ hands during extended periods of operation, thereby improving overall productivity.

User Feedback and Ergonomic Studies

The significance of user feedback and ergonomic studies in the creation of grip designs for power tool switches cannot be underestimated.

Such data is pivotal in refining these designs, ensuring they meet the specific needs and preferences of end-users while also minimizing potential risks associated with prolonged use or operator fatigue.

Furthermore, actively involving users in the design process fosters an approach centered on user needs, ultimately leading to functional and effective power tool switches that enhance productivity and safety.

Significance of user feedback and ergonomic studies in grip design

Valuable insights harvested from detailed user feedback and comprehensive ergonomic studies play a pivotal role in sculpting comfortable, efficient, and safe grip designs for power tool switches, driving the perception of each subtle contour and texture against the palm to a heightened level of precision.

- User feedback provides first-hand information on comfortability, ease of use, as well as potential pain points in using power tool switches.

- Ergonomic studies ensure that grip designs adhere to human factors principles thereby reducing work-related musculoskeletal disorders.

- These insights inform modifications or improvements in design elements such as shape, size and material type which directly affect operator’s productivity.

- Consequently, they contribute towards greater user satisfaction – an essential aspect in maintaining brand loyalty within the competitive power tools market.

Incorporation of user feedback and studies to refine grip designs

Understanding and integrating user feedback along with findings from ergonomic studies into the refining process of handle structures can result in enhanced comfort, improved operability, and reduced risk of injury.

This approach ensures that design modifications are not done arbitrarily but based on empirical evidence and actual user experiences. User feedback provides invaluable insights about grip comfort, usability, and fatigue issues during prolonged use.

Ergonomic studies analyze physiological aspects such as hand size variations, strength distribution patterns, and muscle load during operations. The synergy of these two elements allows for a more nuanced understanding of the complex interaction between the human hand and power tool switches.

Consequently, this leads to refined grip designs that cater to diverse user needs while prioritizing safety measures.

Benefits of involving users in the design process for creating user-centric power tool switches

Transitioning from the pivotal role user feedback plays in refining grip designs, it’s equally critical to delve into the benefits of involving users directly in the design process. This proactive approach facilitates creating power tool switches that are indeed user-centric.

- Enhanced Usability: Engaging users during development stages ensures higher usability standards as designs can be tailored to match their comfort and preference.

- Increased Efficiency: User involvement could lead to innovative solutions that enhance overall efficiency, reducing time and effort spent on operation.

- Safety Improvements: By understanding users’ needs and behaviors, potential safety risks can be identified early and mitigated effectively, thereby ensuring safer operation for end-users.

Thus, incorporating users in the design process is an invaluable strategy for creating more effective and efficient power tool switches.

Case Studies

Delving into Section 6, an examination of specific case studies will provide insights into effective grip designs that have been incorporated in well-received power tools.

A meticulous analysis will be undertaken to understand their contribution towards optimizing switch performance and enhancing the user experience.

The discussion seeks to underline the substantial impact grip design can exert on both operational efficiency and user satisfaction levels, thus highlighting its importance in power tool design and usage.

Analysis of successful grip designs in popular power tools

Examining popular power tools on the market reveals a diverse range of successful grip designs, each engineered to enhance user comfort and control while maximizing operational efficiency.

Notable among these is the pistol grip design, common in drills and impact drivers. This type of grip mimics the shape of a handgun handle, providing optimal balance and ease of use.

Another prevalent grip design is the D-handle, often seen in routers or large circular saws. It offers superior stability during high-power operations.

Finally, palm grips found in sanders or planers are designed with ergonomics in mind, allowing for prolonged use without causing hand fatigue.

All three exemplify how thoughtful grip design contributes to tool functionality and user experience.

The impact of grip design on switch performance and user experience

Influential in increasing the interaction and integration of users with their equipment is the strategic placement and conception of tool controls, demonstrating how seamless switch systems can significantly shape user satisfaction. The grip design plays a pivotal role in enhancing or degrading the performance of power tool switches, thereby impacting user experience.

- Ergonomics: An ergonomically designed grip ensures comfortable handling, reduces fatigue and enhances precise control over switches.

- Safety: Grips with non-slip material reduce risks associated with accidental slippages, providing safe operation.

- Efficiency: The positioning of switches on grips has a direct influence on operational efficiency; placing them closer to fingers allows quick access, reducing time taken for action.

Overall, grip design directly affects user comfortability and efficacy when operating power tools.

Future Trends and Innovations

Emerging trends and innovations in grip design for power tool switches are poised to redefine the user experience and enhance safety standards.

Advancements in materials, specifically anti-vibration technologies and adaptive grip surfaces, are expected to play a pivotal role in this evolution.

Concurrently, the advent of novel technologies or design concepts can potentially revolutionize grip design, thereby transforming its future trajectory.

Emerging trends and innovations in grip design for power tool switches

Recent advancements in grip design for power tool switches have been pivotal in enhancing user comfort, efficiency, and safety. Technological innovations are shaping the future of this industry by integrating ergonomic designs with advanced materials to reduce hand fatigue, increase productivity, and prevent accidents.

The emerging trends include:

- Utilization of 3D printing technology to create customized grips that fit perfectly into a user’s hand.

- The integration of smart sensor technology for enhanced control and safety.

- Use of advanced materials like thermoplastic elastomers for improved durability and comfort.

- Development of anti-vibration systems to minimize the risk of nerve damage from prolonged use.

These developments promise a new era in power tool usage where user well-being is prioritized without compromising performance levels.

Advancements in materials such as anti-vibration technologies and adaptive grip surfaces

Advancements in materials technology are revolutionizing the ergonomics of handheld equipment, with a particular focus on anti-vibration technologies and adaptive surface textures. These innovations provide enhanced comfort and stability, reducing user fatigue and injury risk.

Innovative material application in grip design generates several noteworthy benefits. Anti-vibration materials absorb shock, minimizing hand-arm vibration syndrome (HAVS), commonly associated with prolonged power tool use. Adaptive grip surfaces mold to the user’s hand shape, providing a personalized fit that improves control and reduces muscle strain.

The table below encapsulates the significance of these advancements in enhancing user experience:

| Advancement | User Benefit |

|---|---|

| Anti-Vibration Technology | Minimizes HAVS; increases precision |

| Adaptive Grip Surfaces | Molds to hand shape; reduces muscle strain |

These developments signify a new era of ergonomic design in power tool switches.

Upcoming technologies or design concepts that may revolutionize grip design in the future

Future-oriented technologies and innovative design concepts are on the brink of transforming the ergonomics of handheld equipment, potentially redefining user comfort and control.

One such concept is the application of smart materials, capable of changing properties in response to external stimuli like temperature or pressure. These can be employed to create adaptive grips that adjust in real-time to a user’s hand shape and pressure, thereby reducing fatigue and enhancing precision.

Another promising innovation involves incorporating haptic feedback systems into power tool switches, providing tactile sensations to alert users about operational status or potential hazards.

Furthermore, advancements in nanotechnology could lead to ultra-tough yet lightweight grip designs that significantly reduce strain without compromising durability.

Such revolutionary concepts hold immense potential for optimizing grip design in power tools.

Frequently Asked Questions (FAQs)

The ensuing discourse will delve into the critical subject of grip design in power tool switches and its significance, exploring how it affects usability and safety.

Special attention will be given to the key factors that should be considered when creating a grip design for power tool switches, including the impact on switch responsiveness and durability.

Insightful examples of power tools with superior grip designs will also form part of this examination, providing tangible illustrations of the theoretical elements discussed.

Importance of grip design in power tool switches

Just as a well-fitted glove enhances the dexterity and strength of a hand, an effective grip design in power tool switches can significantly improve user control, efficiency, and safety.

The design of the grip affects how comfortably and securely the tool fits into the operator’s hand, influencing overall task performance. A well-designed grip reduces fatigue, enhances precision, and minimizes the risk of accidental slips or drops.

In addition to physical comfort, it also provides psychological assurance to the user about their ability to control the tool effectively. Therefore, manufacturers should prioritize ergonomic considerations in their designs for power tool switches.

By doing so they not only enhance user experience but also contribute positively towards reducing work-related injuries that arise from poorly designed tools.

Effect of grip design on usability and safety of power tool switches

In examining the interplay between usability and safety in handheld machinery, it becomes evident that the configuration of a user’s grasp significantly influences their interaction with the device. The design of grip on power tool switches contributes to how efficiently a task is executed and how secure the user feels during operation. This is due to the fact that an appropriate grip design reduces hand fatigue, enhances control over machine operations, and minimizes risks associated with accidental switch activation.

| Factors | Impact |

|---|---|

| Hand Fatigue | Poorly designed grips can lead to rapid exhaustion impacting work efficiency negatively. |

| Control Over Operation | An ergonomic grip ensures better control over tool operation enhancing precision. |

| Safety Risks | Good grip designs reduce chances of accidental switch activations ensuring safe working conditions. |

Key factors to consider in grip design for power tool switches

According to a 2016 study by the National Institute for Occupational Safety and Health, nearly 30% of injuries in construction work were related to handheld power tools, underscoring the critical need for thoughtful consideration of factors such as comfort, ergonomics, and user-friendliness when conceptualizing handle layouts for these devices.

Paramount among these factors is grip design, which directly influences tool operation and control. Optimal grip design should promote natural hand positioning to minimize muscle strain and fatigue. Additionally, it should facilitate intuitive interaction with switches without compromising safety.

Material choice also plays a role – materials that allow secure grasp even under sweaty or oily conditions can greatly enhance worker safety. Lastly, grips should be designed considering the variability in users’ hand size and strength.

Impact of grip design on switch responsiveness and durability

Contemplating the functionality and longevity of handheld devices, it becomes evident that handle layout can significantly influence not only switch responsiveness but also durability. The ergonomic design of grips can contribute to enhanced tactile feedback, enabling users to operate switches more efficiently. Amplified responsiveness often leads to reduced wear-and-tear, enhancing the device’s lifespan.

Furthermore, a well-designed grip accommodates various hand sizes and shapes while mitigating undue strain on the fingers and wrist. Consequently, this reduces repetitive stress injuries among operators over time.

Equally significant is the grip material which should be robust enough to endure prolonged usage without deteriorating rapidly or compromising the switch function. Thus, a judicious blend of ergonomics and material selection in grip design could indeed dictate power tool switch performance and endurance.

Examples of power tools with excellent grip design

Casting a spotlight on the realm of handheld devices, it is intriguing to note the diverse array of machinery that exemplifies superior handle composition for optimal user comfort and efficient functionality.

Several power tools stand out in this regard, demonstrating how an innovative grip design can significantly enhance their overall performance.

- Makita XDT13Z 18V LXT Lithium-Ion Brushless Cordless Impact Driver: Features a rubberized soft grip handle that provides increased comfort on the job.

- DEWALT DCD791B 20V MAX XR Li-Ion 0.5′ Brushless Compact Drill/Driver: Boasts an ergonomic comfort grip handle that provides ideal balance and tool control.

- Milwaukee M18 Fuel Hammer Drill Driver: Has an ergonomically designed handle with soft-grip contouring for added comfort and reduced fatigue.

- Bosch GSR12V-140FCB22 Cordless Electric Screwdriver 12V Kit: Incorporates a customizable FlexiClick 5-in-1 system which includes multiple attachments for best user flexibility in tight spaces.

Conclusion

In conclusion, the discourse has offered a comprehensive exploration of the vital role grip design plays in power tool switches, underscoring its significance in ensuring comfort, control and safety during operations.

The information provided herein reinforces the assertion that attention to grip design is not a mere aesthetic or peripheral consideration but rather a core factor influencing user experience and safety.

As such, it is strongly suggested that individuals seeking power tools prioritize considerations related to grip design alongside other technical specifications to enhance their overall operational experience and safety.

The key points discussed

Delving into the details, the blog post underscores the paramount importance of grip design in power tool switches. It discusses how grip design contributes to user comfort, control, efficiency, and safety. The post emphasizes that a well-designed grip can significantly reduce fatigue and injury risk associated with prolonged tool usage.

The discussion also highlights various aspects of grip design such as shape, size, material choice, and positioning on the switch. It notes how these factors interact together to determine the overall usability and effectiveness of power tools.

Furthermore, the post draws attention towards industry standards for designing ergonomic grips and stresses the need for continuous innovation for improvement. Overall, this analysis effectively demonstrates that grip design plays an integral role in enhancing productivity while ensuring user safety in power tool operations.

The importance of grip design in power tool switches for comfort, control, and safety

Underscoring the significance of ergonomics in handheld machinery, the tactile interface between human and device emerges as a cornerstone for ensuring user comfort, command precision, and operational safety.

The grip design in power tool switches holds a pivotal role in achieving these parameters. An optimally designed grip reduces physical strain on the operator, enhancing comfort and increasing productivity during prolonged use periods.

It also affords superior control over tool operation by providing an ergonomic fit that ensures precise manipulation even under demanding conditions.

Safety is another crucial consideration; well-designed grips contribute to this by offering firm handhold stability, thereby preventing accidental slips or drops that could lead to injury or damage.

Therefore, grip design should be prioritized when designing power tools for effective performance while minimizing risk factors.

Prioritize grip design when choosing power tools to enhance their overall experience

Building upon the previously established significance of grip design in power tool switches, it is crucial to shift focus towards its practical applications. A discerning user should prioritize this aspect while selecting power tools, as it can significantly enhance their overall experience.

- First and foremost, an ergonomically designed grip ensures a comfortable hold which is key for prolonged usage without experiencing fatigue.

- Secondly, a well-designed grip aids in maintaining optimal control over the tool’s movements which directly impacts precision and work quality.

- Lastly, incorporating safety features within the grip design such as non-slip surfaces or lock-on buttons can drastically reduce risk of accidents while operating these devices.

In essence, considering grip design when choosing power tools manifests in improved comfortability, enhanced control and increased safety.

Author

Hello, my name is Eva Xia, and I am currently the Marketing Manager at Yueqing Weup Technology Co., Ltd, located in Wenzhou, Zhejiang, China. With over a decade of experience in the accounting field, I have developed extensive knowledge and skills that enable me to excel in my role. Additionally, I have spent two years working as an English teacher, which enhanced my communication abilities and instilled discipline within me.

Having gained more than three years of valuable experience in overseas sales, I have had the opportunity to expand my horizons and develop a deeper understanding of the commercial landscape. This exposure has nurtured my business understanding and allowed me to navigate diverse markets confidently.

However, despite my accomplishments thus far, I remain dedicated to continuous growth and learning. My current area of focus revolves around electronic switches. It is a fascinating and dynamic field that constantly evolves with technological advancements. By delving deeper into this realm, I aim to enhance my professional knowledge and stay ahead of industry trends.

In summary, as a Marketing Manager at Yueqing Weup Technology Co., Ltd., I bring forth a wealth of experience in accounting coupled with the valuable skills honed during my time as an English teacher. Furthermore, my extensive overseas sales expertise has sharpened my business acumen. With a relentless thirst for knowledge and a specific interest in electronic switches, I strive to enhance my professional capabilities further while contributing positively to our organization’s success.

Get in Touch for More Insights!

If you’ve found the information helpful and want to learn more, I encourage you to reach out. Whether your questions concern our latest industry trends, electronic switches, or other market insights, I’m here to help!

Don’t hesitate to drop me an email at the below table.

I am looking forward to hearing from you soon!

Eva Xia,

Marketing Manager at Yueqing Weup Technology Co., Ltd